A kokarin samar da sabbin hanyoyin kera semiconductor da kuma tsarin metrology na sub-micron, "tushe" da "hanyar" su ne manyan ma'auni guda biyu. Yayin da masu tsara injina ke kokarin samar da ingantaccen aiki da kuma maimaituwa a matakin nanometer, zabi tsakaninJagorar ɗaukar iska ta granitekuma jagorar bearing na gargajiya ta zama muhimmin shawara a fannin injiniya. Bugu da ƙari, kayan da aka yi amfani da su a cikin injin da kansa - kwatanta granite da yumbu masu aiki mai ƙarfi - yana ƙayyade iyakokin zafi da girgiza na tsarin gaba ɗaya.

Kwatanta Jagororin Bearing Air Bearing na Granite da Jagororin Bearing na Roller

Babban bambanci tsakanin waɗannan tsarin guda biyu yana cikin hanyarsu ta tallafawa kaya da kuma sarrafa gogayya.

Jagororin Haɗakar Iska ta Graniteyana wakiltar kololuwar motsi mara gogayya. Ta hanyar amfani da siririn fim na iska mai matsewa—yawanci tsakanin microns 5 zuwa 20—ƙarar da ke motsi a zahiri tana shawagi a saman layin jagorar granite.

-

Babu Gogayya da Lalacewa:Saboda babu taɓawa ta zahiri, babu wani "tsari" (ƙararrawa mai tsayawa) da za a shawo kansa, kuma tsarin ba ya taɓa lalacewa. Wannan yana ba da damar yin nazari mai santsi da sauri akai-akai.

-

Matsakaicin Kuskure:Ɗaya daga cikin muhimman fa'idodin bearings na iska shine ikonsu na "matsakaici" fitar da ƙananan kurakurai na saman layin granite, wanda ke haifar da motsi madaidaiciya fiye da layin dogo da kansa.

-

Tsafta:Ba tare da buƙatar shafa mai ba, waɗannan jagororin sun dace da ɗaki mai tsabta, wanda hakan ya sa su zama misali don duba wafer da kuma samar da nunin faifai mai faɗi.

Jagororin Bearing na Nada, akasin haka, sun dogara ne akan taɓawar jiki ta na'urorin birgima na ƙarfe ko ƙwallo masu inganci.

-

Ƙarfin Load Mafi Kyau:Don aikace-aikacen da suka shafi manyan kaya ko ƙarfin yankewa (kamar niƙa daidai), bearings na birgima suna ba da ƙarfi mai yawa da ƙarfin ɗaukar kaya.

-

Sauƙin Aiki:Ba kamar bearings na iska ba, waɗanda ke buƙatar tsarin samar da iska mai tsafta da kuma tsarin tacewa akai-akai, bearings na birgima suna da "haɗin gwiwa da kunnawa."

-

Tsarin Karami:Bearings na inji galibi suna iya ɗaukar manyan kaya a ƙaramin sawun ƙafa idan aka kwatanta da babban yankin saman da ake buƙata don ingantaccen kushin ɗaukar iska.

Duk da cewa bearings ɗin naɗawa suna da ƙarfi kuma suna da araha ga daidaiton gabaɗaya, bearings ɗin iska sune zaɓin da ba za a iya sasantawa ba don aikace-aikace inda "lambobin sadarwa" shine maƙiyin daidaito.

Amfani da Jagororin Bearing na Iska: Inda Daidaito Ya Haɗu da Sauƙi

Amfani da jagororin ɗaukar iska ya faɗaɗa fiye da dakin gwaje-gwaje zuwa samar da kayayyaki masu yawa a masana'antu.

A cikinMasana'antar SemiconductorAna amfani da bearings na iska a cikin lithography da wafer probing. Ikon motsawa a cikin babban gudu ba tare da girgiza ba yana tabbatar da cewa tsarin scanning bai shigar da kayan tarihi a cikin sikelin nanometer ba.

In Hotunan Dijital da Babban Tsarin Dubawa, saurin da iska ke yi akai-akai yana da matuƙar muhimmanci. Duk wani "haɗuwa" ko girgiza daga na'urar ɗaukar hoto zai haifar da "haɗewa" ko karkacewa a cikin hoton ƙarshe mai ƙuduri mai girma.

Injinan Aunawa Masu Daidaito (CMM)dogara da jagororin ɗaukar iska na granite don tabbatar da cewa na'urar na iya motsawa da taɓawa mafi sauƙi. Rashin gogayya yana bawa tsarin sarrafa na'urar damar amsawa nan take ga mafi yawan canje-canjen saman ɓangaren da ake aunawa.

Tushen Kayan Aiki: Granite vs. Ceramic don Tushen Inji

Aikin kowane tsarin jagora yana da iyaka saboda kwanciyar hankalin tushen da aka ɗora masa. Tsawon shekaru da yawa, granite shine matsayin masana'antu, amma yumbu na zamani (kamar Alumina ko Silicon Carbide) suna ƙirƙirar wani yanki a cikin aikace-aikacen da suka yi matuƙar aiki.

Tushen Injin Dutseya kasance zaɓin da aka fi so ga kashi 90% na aikace-aikacen da suka dace sosai.

-

Kayayyakin Damping:Granite ta fi kyau a zahiri wajen shan girgiza mai yawan gaske, wanda yake da mahimmanci ga ilimin metrology.

-

Ingancin Farashi:Ga manyan tushe (har zuwa mita da yawa), granite ya fi araha wajen samowa da sarrafawa fiye da yumbu na fasaha.

-

Rashin ƙarfin zafi:Girman dutse mai girma yana nufin yana amsawa a hankali ga canje-canjen yanayin zafi na yanayi, yana samar da yanayi mai kyau don aunawa na dogon lokaci.

Tushen Injin YumbuAna amfani da (musamman Alumina) lokacin da ake buƙatar aikin "na ƙarshe".

-

Babban Rabon Tauri da Nauyi:Yumbu ya fi dutse tauri fiye da dutse mai nauyi iri ɗaya. Wannan yana ba da damar hanzartawa da rage matakan motsi ba tare da lalata tushen ba.

-

Tsarin Zafi Mai Tsanani:Wasu yumbu suna da ma'aunin faɗaɗa zafi (CTE) har ma ƙasa da granite, kuma mafi girman ƙarfin watsa zafi yana ba tushen damar isa ga daidaiton zafi da sauri.

-

Tauri:Yumbura kusan ba sa karce kuma suna jure wa lalacewar sinadarai, kodayake sun fi karyewa kuma sun fi tsada sosai don ƙera su a manyan tsare-tsare.

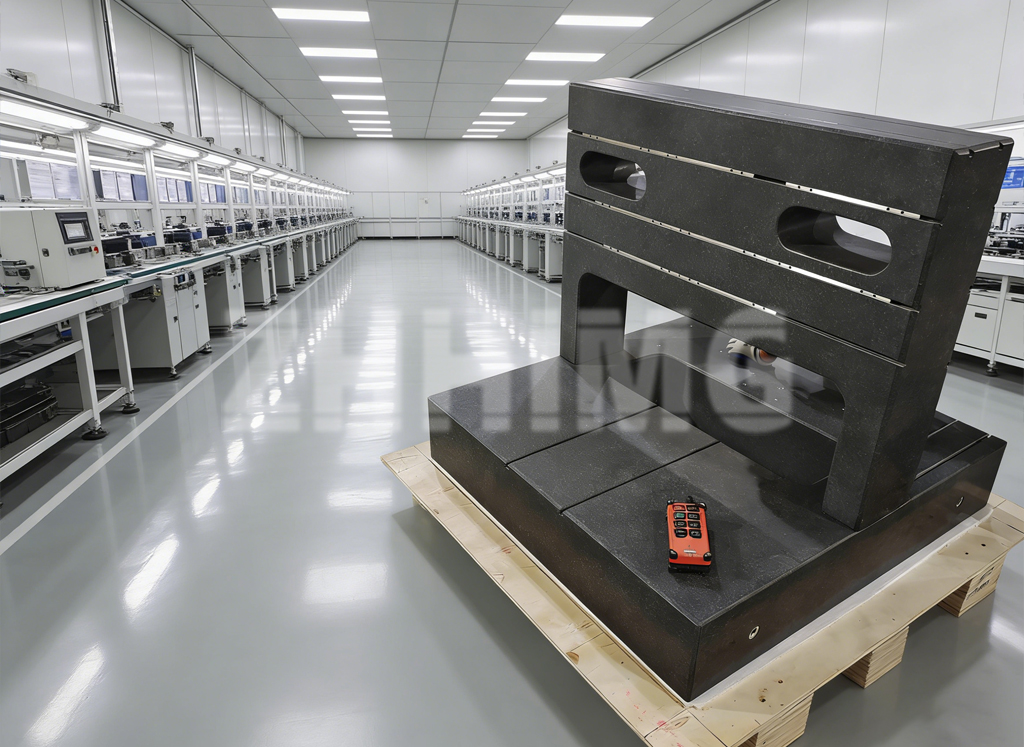

Alƙawarin ZHHIMG ga Kimiyyar Kayan Aiki

A ZHHIMG, mun yi imanin cewa mafi kyawun mafita ba kasafai ake amfani da hanyar da ta dace da kowa ba. Ƙungiyar injiniyanmu ta ƙware wajen haɗa waɗannan fasahohin ta hanyar haɗaka. Sau da yawa muna amfani da nauyin girgiza-damtse na tushen granite don tallafawa motsi mara gogayya na jagorar ɗaukar iska, wani lokacin muna haɗa kayan yumbu a wurare masu mahimmanci na lalacewa ko tauri.

A matsayinmu na babban masana'anta, muna samar wa kasuwar duniya da tabbacin yanayin ƙasa na dutse mai daraja da kuma ƙwarewar fasaha ta tsarin motsi na zamani. Cibiyar kera mu ta haɗa ƙwarewar gargajiya ta amfani da hannu—ƙwarewa da ake buƙata don cimma daidaiton da ake buƙata don bearings na iska—tare da injinan CNC na zamani da kuma laser interferometry.

Kammalawa: Injiniyan Nasararka

Zaɓi tsakanin granite da yumbu, ko tsakanin iska da bearings na inji, a ƙarshe yana ƙayyade iyakokin aiki na fasahar ku. Ga injiniyoyi a fannin sararin samaniya, semiconductor, da metrology, fahimtar waɗannan bambance-bambancen shine mabuɗin ƙirƙira. ZHHIMG Group na ci gaba da tura iyakokin abin da zai yiwu a cikin motsi daidai, yana tabbatar da cewa injin ku yana tsaye akan tushe na cikakken kwanciyar hankali kuma yana motsawa cikin daidaito mara misaltuwa.

Lokacin Saƙo: Janairu-22-2026