Yayin da masana'antu na duniya ke ci gaba da tafiya cikin sauri zuwa ga daidaito mafi girma, saurin da ya fi girma, da kuma kwanciyar hankali mafi girma, kamfanonin kera sassan daidaito suna fuskantar matsin lamba mai yawa don ba kawai su samar da juriya mai ƙarfi ba, har ma da aminci na dogon lokaci. A cikin wannan mahallin, sassan granite masu daidaito sun zama ginshiƙi a cikin matakan motsi masu daidaito, tsarin metrology na ci gaba, da kayan aikin masana'antu masu inganci. Abubuwan da suka keɓance na musamman suna ba da damar matakan aiki waɗanda ke da wahalar cimmawa tare da tsarin ƙarfe na gargajiya.

Wannan labarin yana bincika kera sassan granite masu daidaito, muhimmiyar rawar da suke takawa a tsarin matakan motsi masu daidaito, da kuma yanayin masana'antu da ke tsara buƙata tsakanin kamfanonin kera sassan daidaito a Turai da Arewacin Amurka. Hakanan ya bayyana yadda ZHHIMG ke tallafawa abokan ciniki na duniya tare da mafita na granite da aka ƙera don yanayin masana'antu masu wahala.

Daidaitattun Abubuwan Granite: Amfanin Kayan Aiki da Darajar Injiniya

Ana amfani da sassan granite masu daidaito sosai a aikace-aikace inda kwanciyar hankali na girma, rage girgiza, da daidaiton zafi suke da mahimmanci. Idan aka kwatanta da ƙarfe, ƙarfe mai siminti, ko tsarin aluminum, granite yana ba da haɗin halayen zahiri waɗanda suka dace da buƙatun tsarin daidaito sosai.

Granite yana da ƙarancin ma'aunin faɗaɗa zafi, wanda ke ba da damar abubuwan da ke ciki su kiyaye daidaiton yanayin geometric ko da a ƙarƙashin yanayin zafi mai canzawa. Wannan halayyar tana da mahimmanci musamman a cikinmatakan motsi masu matuƙar daidaito, inda dole ne a kiyaye daidaiton matsayi na matakin micron da sub-micron a tsawon tsawon zagayowar aiki mai tsawo.

Bugu da ƙari, tsarin kristal na ciki na dutse mai yawan yawa na baƙi yana ba da kyakkyawan damƙar girgiza. Wannan yana rage watsawar rikice-rikice na waje kuma yana inganta aiki mai ƙarfi a cikin dandamalin motsi, tsarin gani, da kayan aikin semiconductor. Granite kuma yana da juriya ga tsatsa kuma ba shi da maganadisu, wanda hakan ya sa ya dace da yanayin tsafta da aikace-aikacen aunawa masu mahimmanci.

Kayan Aikin Granite Masu Daidaito: Daga Dutse Mai Daci zuwa Tsarin da Aka Gama

Kera kayan aikin granite masu daidaito tsari ne na musamman wanda ya haɗa da zaɓin kayan aiki, injin sarrafawa, da kuma duba daidaito mai girma. Ba kamar yadda aka saba sarrafa dutse ba, kera granite masu daidaito yana mai da hankali kan cimma daidaito, daidaito, da juriyar lissafi da aka auna a cikin microns.

Tsarin yana farawa da zaɓar tubalan granite da aka yi da kyau. Granite ne kawai mai tsarin hatsi iri ɗaya, yawan yawa, da ƙarancin lahani na ciki ya dace da aikace-aikacen daidai. Da zarar an zaɓa, kayan yana fuskantar matakan rage damuwa da tsufa don tabbatar da kwanciyar hankali na dogon lokaci.

Ana yin injina da niƙa a cikin yanayin da zafin jiki ke sarrafawa ta amfani da kayan aiki masu inganci. Ana amfani da niƙa saman, lapping, da kuma kammalawa mai kyau don cimma daidaiton da ake buƙata da kuma lanƙwasa.ingancin farfajiyaGa abubuwa masu rikitarwa, ana haɗa haƙoran daidai, ramin rami, da abubuwan da aka saka a ciki ba tare da lalata amincin tsarin ba.

A duk lokacin da ake kera na'urorin aunawa, ana gudanar da tantance girma ta amfani da kayan aikin aunawa masu daidaito, tsarin auna laser, da kuma na'urorin aunawa masu daidaitawa. Wannan yana tabbatar da cewa kowane ɓangaren granite mai daidaito ya cika ƙa'idodin daidaito da aka ƙayyade kafin a kawo shi.

Matakan Motsi Mai Tsanani: Bukatun Tsarin da Masu Gyaran Aiki

Matakan motsi masu daidaito sosai suna da mahimmanci ga aikace-aikace kamar lithography na semiconductor, daidaitawar gani, sarrafa laser, da tsarin dubawa na zamani. Waɗannan matakai suna buƙatar tauri na musamman, kwanciyar hankali na zafi, da damping don cimma motsi mai maimaitawa, mai sauri, da daidaito mai yawa.

Tsarin da aka gina da dutse yana samar da tushe mai kyau ga irin waɗannan tsarin.Tushen dutse masu daidaitokuma gadoji suna tallafawa injinan layi, bearings na iska, da tsarin jagora yayin da suke kiyaye daidaito a ƙarƙashin nauyin da ke aiki. Halayen damfara na dutse suna inganta lokacin daidaitawa da rage kurakuran wuri da girgiza ke haifarwa.

A cikin zane-zane da yawa, ana haɗa sassan granite tare da fasahar ɗaukar iska don cimma motsi mara misaltuwa. Wannan haɗin yana ba da damar sanya wuri mai santsi, mai maimaitawa tare da ƙarancin lalacewa, yana tallafawa tsawon rai na sabis da rage buƙatun kulawa.

Haɗakar Granite Mai Daidaito a Tsarin Matakin Motsi

Nasarar haɗa sassan granite masu daidaito cikin matakan motsi masu matuƙar daidaito yana buƙatar haɗin gwiwa tsakanin masu tsara tsarin da masana'antun kayan aiki. Dole ne a yi la'akari da abubuwa kamar ƙirar haɗin haɗin gwiwa, rarraba kaya, da kuma sarrafa zafi tun da wuri a cikin tsarin haɓakawa.

Sau da yawa ana ƙera gine-ginen granite na musamman don dacewa da injinan layi, tsarin ɓoye bayanai, sarrafa kebul, da buƙatun injin tsabtace gida ko na shara. Kamfanonin kera kayan aikin daidaici suna ƙara dogaro da mafita na granite na musamman maimakon sassan kundin adireshi na yau da kullun don inganta aikin tsarin.

ZHHIMG tana aiki kafada da kafada da masana'antun kayan aiki don haɓaka sansanonin granite, gantries, da firam waɗanda suka dace da takamaiman tsarin matakan motsi. Wannan hanyar haɗin gwiwa tana tabbatar da daidaito, daidaito, da kwanciyar hankali na dogon lokaci a cikin aikace-aikacen da ake buƙata.

Sauye-sauyen Masana'antu Suna Bukatar Daidaita Sassan Granite

Sau da yawa yanayin manyan matakai yana haifar da ƙaruwar buƙatar sassan granite masu daidaito a faɗin Turai da Arewacin Amurka. Ci gaba da haɓaka masana'antar semiconductor ya ƙara yawan buƙatun dandamalin injina masu ƙarfi da tsarin dubawa. A lokaci guda, ci gaba a fannin na'urorin gani, na'urorin photonics, da na'urorin laser sun ɗaga tsammanin daidaiton matsayi da kwanciyar hankali a muhalli.

Ana sarrafa kansa da kuma kera kayayyaki na dijital suma suna taimakawa wajen wannan yanayin. Yayin da layukan samarwa ke ƙara zama masu sarrafa kansu, tsarin aunawa a layi da kuma tsarin motsi mai sauri dole ne su ci gaba da aiki ba tare da raguwar gudu ba. Tsarin da aka gina bisa dutse yana taimakawa wajen tabbatar da aiki mai daidaito a tsawon lokacin aiki.

Waɗannan abubuwan sun sanya daidaitattun sassan granite a matsayin abubuwan dabaru a cikin sarkar samar da kayayyaki na manyan kamfanonin kera kayan aikin daidaitacce.

Ƙarfin ZHHIMG a Masana'antar Granite Mai Daidaito

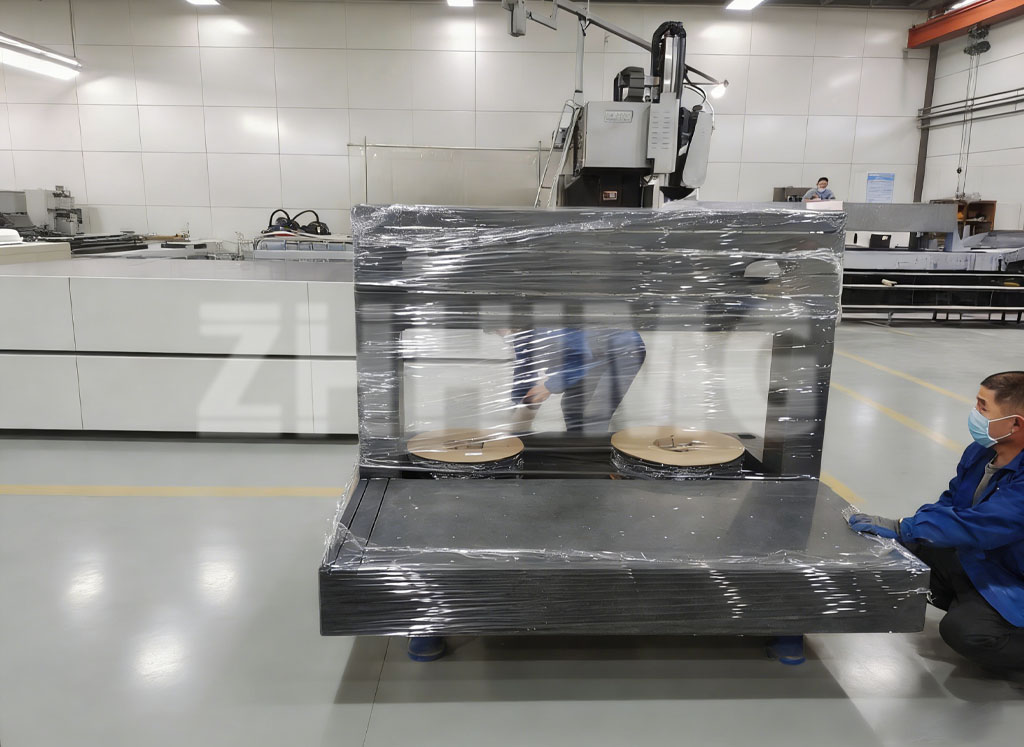

ZHHIMG ta ƙware wajen kera kayan granite masu daidaito ga abokan cinikin masana'antu na duniya. Ta hanyar haɗa kayan granite baƙi masu inganci tare da fasahar niƙa da dubawa ta zamani, ZHHIMG tana samar da kayan da suka dace da ƙa'idodin daidaito na duniya.

Fayil ɗin samfuran kamfanin ya haɗa da tushen granite don matakan motsi masu daidaito, faranti na saman daidai, firam ɗin injina, da tsarin granite na musamman. Ana ƙera kowane sashi a ƙarƙashin yanayin muhalli mai sarrafawa kuma ana tabbatar da shi ta hanyar cikakkun hanyoyin dubawa.

Tare da gogewa wajen tallafawa abokan ciniki a cikin kayan aikin semiconductor, tsarin metrology, da kuma sarrafa kansa mai ƙarfi, ZHHIMG ba wai kawai yana ba da kayan aiki ba, har ma da tallafin fasaha a duk lokacin ƙira da haɗin kai.

Kammalawa

Yayin da masana'antar kera kayayyaki masu inganci ke ci gaba da ci gaba, muhimmancin sassan granite masu daidaito a cikin tsarin motsi da kayan aikin metrology zai ƙaru ne kawai. Haɗinsu na musamman na kwanciyar hankali na zafi, rage girgiza, da juriya ya sa su zama zaɓi mafi kyau ga matakan motsi masu daidaito da aikace-aikacen masana'antu masu inganci.

Ga kamfanonin kera kayan aiki masu inganci waɗanda ke neman ingantattun mafita na dogon lokaci, tsarin da aka gina bisa dutse yana ba da fa'idodi masu kyau da kuma zagayowar rayuwa. Ta hanyar ƙwarewa mai himma a fannin kera granite mai daidaito, ZHHIMG ta ci gaba da jajircewa wajen tallafawa abokan cinikin duniya da mafita masu inganci waɗanda suka dace da buƙatun masana'antar zamani.

Lokacin Saƙo: Janairu-21-2026