;

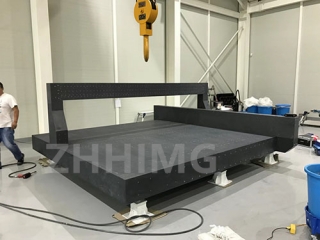

A fannin kera semiconductor, daidaito shine tushen ingancin samfura da aiki. Kayan aikin auna semiconductor, a matsayin babbar hanyar tabbatar da daidaiton samarwa, suna sanya ƙa'idodi kusan masu tsauri kan daidaiton abubuwan da ke cikin sa. Daga cikinsu, dandamalin granite, tare da ingantaccen kwanciyar hankali na zafi, yana taka muhimmiyar rawa a cikin kayan aikin auna semiconductor. Wannan labarin zai gudanar da cikakken bincike kan aikin daidaiton zafi na dandamalin granite a cikin kayan aikin auna semiconductor ta hanyar ainihin bayanan gwaji.

Bukatun da ake buƙata don tabbatar da kwanciyar hankali na zafi na kayan aikin aunawa a cikin masana'antar semiconductor

Tsarin kera semiconductor yana da matuƙar rikitarwa da daidaito, kuma faɗin layukan da'ira a kan guntu ya shiga matakin nanometer. A cikin irin wannan tsarin kera mai inganci, ko da ƙaramin canjin zafin jiki na iya haifar da faɗaɗa zafi da matsewar kayan aiki, wanda hakan ke haifar da kurakuran aunawa. Misali, a cikin tsarin photolithography, idan daidaiton auna kayan aikin aunawa ya karkata da nanometer 1, yana iya haifar da matsaloli masu tsanani kamar gajerun da'ira ko da'ira a buɗe a cikin da'ira akan guntu, wanda ke haifar da wargaza guntu. A cewar ƙididdigar bayanai na masana'antu, ga kowane canjin zafin jiki na 1℃, dandamalin kayan aikin auna kayan ƙarfe na gargajiya na iya fuskantar canje-canje masu girma na nanometers da yawa. Duk da haka, kera semiconductor yana buƙatar a sarrafa daidaiton aunawa a cikin ±0.1 nanometers, wanda ke sa kwanciyar hankali na zafi ya zama babban abin da ke tantance ko kayan aikin aunawa za su iya biyan buƙatun kera semiconductor.

Fa'idodin ka'idar kwanciyar hankali na yanayin zafi na dandamalin dutse

Granite, a matsayin wani nau'in dutse na halitta, yana da ƙaramin lu'ulu'u na ma'adinai na ciki, tsari mai yawa da daidaito, kuma yana da fa'idar yanayi na kwanciyar hankali na zafi. Dangane da ma'aunin faɗaɗa zafi, ma'aunin faɗaɗa zafi na granite yana da ƙasa sosai, gabaɗaya yana farawa daga 4.5 zuwa 6.5 × 10⁻⁶/K. Sabanin haka, ma'aunin faɗaɗa zafi na kayan ƙarfe na yau da kullun kamar ƙarfe na aluminum yana da girman 23.8 × 10⁻⁶/K, wanda ya ninka na granite sau da yawa. Wannan yana nufin cewa a ƙarƙashin yanayin bambancin zafin jiki iri ɗaya, canjin girma na dandamalin granite ya fi ƙanƙanta fiye da na dandamalin ƙarfe, wanda zai iya samar da ma'aunin ma'auni mafi karko don kayan aikin auna semiconductor.

Bugu da ƙari, tsarin lu'ulu'u na dutse yana ba shi kyakkyawan daidaito na watsa zafi. Lokacin da aikin kayan aiki ke haifar da zafi ko canjin yanayin zafi na yanayi, dandamalin dutse zai iya kawar da zafi cikin sauri da daidaito, yana guje wa yanayin zafi mai zafi ko sanyaya sama, ta haka ne zai kiyaye daidaiton zafin jiki na dandamalin yadda ya kamata da kuma tabbatar da daidaiton ma'auni.

Tsarin da hanyar auna daidaiton zafi

Domin mu tantance daidaiton yanayin zafi na dandamalin granite a cikin kayan aikin auna semiconductor, mun tsara tsarin aunawa mai tsauri. Zaɓi kayan aikin auna wafer na semiconductor mai inganci, wanda aka sanye shi da dandamalin granite da aka sarrafa sosai. A cikin yanayin gwaji, an kwaikwayi kewayon bambancin zafin jiki na gama gari a cikin taron masana'antar semiconductor, wato, a hankali yana dumama daga 20℃ zuwa 35℃ sannan ya sanyaya zuwa 20℃. Duk aikin ya ɗauki tsawon awanni 8.

A kan dandamalin granite na kayan aikin aunawa, ana sanya wafers na silicon masu inganci, kuma ana amfani da na'urori masu auna motsi tare da daidaiton nanoscale don sa ido kan canje-canjen matsayi tsakanin wafers na silicon da dandamali a ainihin lokaci. A halin yanzu, ana shirya na'urori masu auna zafin jiki masu inganci da yawa a wurare daban-daban a kan dandamali don sa ido kan rarraba zafin jiki a saman dandamali. A lokacin gwajin, an yi rikodin bayanan ƙaura da bayanan zafin jiki a kowane minti 15 don tabbatar da cikar da daidaiton bayanan.

Bayanan da aka auna da kuma nazarin sakamako

Alaƙar da ke tsakanin sauyin zafin jiki da canje-canjen girman dandamali

Bayanan gwaji sun nuna cewa lokacin da zafin jiki ya tashi daga 20℃ zuwa 35℃, canjin girman layi na dandamalin granite ya yi ƙanƙanta ƙwarai. Bayan lissafi, a duk tsawon tsarin dumama, matsakaicin faɗaɗa layi na dandamalin shine nanomita 0.3 kawai, wanda ya yi ƙasa da kewayon haƙurin kuskure don daidaiton ma'auni a cikin hanyoyin kera semiconductor. A lokacin matakin sanyaya, girman dandamalin zai iya komawa gaba ɗaya zuwa yanayin farko, kuma ana iya yin watsi da yanayin jinkirin girman canji. Wannan halayyar kiyaye canje-canje masu ƙarancin girma ko da a ƙarƙashin manyan canjin zafin jiki yana tabbatar da kwanciyar hankali na yanayin zafi na dandamalin granite.

Binciken daidaiton zafin jiki a saman dandamali

Bayanan da na'urar auna zafin jiki ta tattara sun nuna cewa yayin aikin kayan aiki da kuma tsarin canjin zafin jiki, rarraba zafin jiki a saman dandamalin granite yana da daidaito sosai. Ko da a lokacin da zafin jiki ya fi canzawa sosai, bambancin zafin jiki tsakanin kowane wurin aunawa akan farfajiyar koyaushe ana sarrafa shi a cikin ±0.1℃. Rarraba zafin jiki iri ɗaya yana hana lalacewar dandamali ta hanyar damuwa mara daidaituwa ta zafi, yana tabbatar da daidaito da kwanciyar hankali na saman ma'aunin aunawa, da kuma samar da ingantaccen yanayin aunawa ga kayan aikin metrology na semiconductor.

Idan aka kwatanta da dandamalin kayan gargajiya

An kwatanta bayanan da aka auna na dandamalin granite da na kayan aikin auna semiconductor iri ɗaya ta amfani da dandamalin gami na aluminum, kuma bambance-bambancen sun kasance masu mahimmanci. A ƙarƙashin yanayin canjin zafin jiki iri ɗaya, faɗaɗa layi na dandamalin gami na aluminum yana da girman nanomita 2.5, wanda ya fi sau takwas na dandamalin dutse. A halin yanzu, rarraba zafin jiki a saman dandamalin gami na aluminum bai daidaita ba, tare da matsakaicin bambancin zafin jiki ya kai 0.8℃, wanda ke haifar da ɓarna a fili na dandamalin kuma yana shafar daidaiton ma'auni sosai.

A cikin ainihin duniyar kayan aikin nazarin yanayin semiconductor, dandamalin granite, tare da ingantaccen kwanciyar hankali na zafi, sun zama ginshiƙi wajen tabbatar da daidaiton ma'auni. Bayanan da aka auna sun tabbatar da ingantaccen aikin dandamalin granite wajen mayar da martani ga canje-canjen zafin jiki, suna ba da ingantaccen tallafin fasaha ga masana'antar kera semiconductor. Yayin da hanyoyin kera semiconductor ke ci gaba zuwa ga daidaito mafi girma, fa'idar kwanciyar hankali na yanayin zafi na dandamalin granite za ta ƙara bayyana, tana ci gaba da haifar da sabbin abubuwa da ci gaba a masana'antar.

Lokacin Saƙo: Mayu-13-2025