Yayin da masana'antar semiconductor ke bin ƙa'idar aiki ta sub-2nm, raguwar kuskuren injiniya ta kusan ɓace. A cikin wannan yanayi mai cike da matsaloli, kwanciyar hankali na ɗakin aiwatarwa ba shine abin damuwa na biyu ba; shine babban ƙalubalen da ke tattare da yawan amfanin ƙasa. A ZHHIMG, muna lura da wani babban sauyi a yadda OEMs na duniya ke tunkarar ingancin tsarin kayan aikin jari na semiconductor.

Ilimin Halittar Shiru: Dabaru Masu Ingantaccen Tsarin Rage Girgiza

A cikin ƙera wafer na zamani, girgizar da aka taɓa ɗauka a matsayin "hayaniyar bango" yanzu ta zama bala'i. Ko dai ƙananan juyawa ne daga tsarin HVAC na cibiyar ko kuma rashin ƙarfin lantarki na ciki na matakin ɗaukar hoto mai sauri, makamashin da ba a sarrafa shi ba yana fassara kai tsaye zuwa kurakurai masu rufewa da alamu masu duhu.

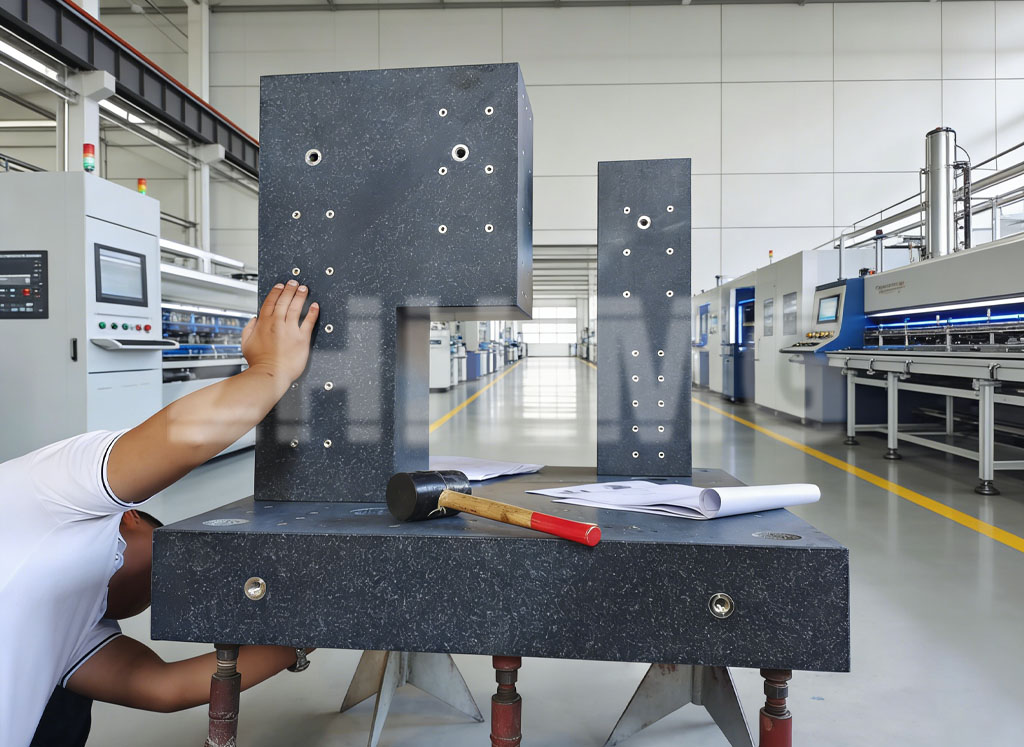

Dabaru na rage girgiza a yanzu a masana'antar semiconductor sun rikide zuwa tsarin gine-gine mai matakai da yawa. Duk da cewa rage girgiza - amfani da kayan aiki masu yawa kamar simintin ma'adinai ko granite daidai - shine tushen, muna ganin ƙaruwar haɗin gwiwar rage girgiza.

Tsarin aiki yana amfani da masu kunna piezoelectric da na'urori masu auna sigina na ainihin lokaci don "soke" girgiza ta hanyar samar da mitoci masu hana faruwa. Duk da haka, ingancin tsarin aiki yana da iyaka ta asali saboda rabon damping na kayan tushe. Wannan shine inda ƙwarewar ZHHIMG a cikin kayan gini masu yawan damping ya zama mahimmanci. Ta hanyar haɗa kayan lantarki masu aiki tare da granite mara aiki ko tushe mai haɗawa, muna samar da "Yankin Shiru" inda nano-positioning zai iya faruwa ba tare da tsangwama ba.

Tashin Motsin Rashin Tausayi: Fasahar Haɗa Iska

Bukatar ƙarin ƙarfin aiki ya tura bearings na injiniya na gargajiya zuwa iyakarsu. Gogewa yana haifar da zafi, kuma zafi yana haifar da faɗaɗa zafi - maƙiyin daidaito. Wannan ya haifar da amfani da shi sosaifasahar ɗaukar iska don matakan daidaito.

Bearings na iska suna ɗaukar nauyi akan siririn fim na iska mai matsin lamba, yawanci kauri ne kawai da microns. Saboda babu hulɗa ta zahiri, babu gogayya mara tsayawa (stiction). Wannan yana ba da damar:

-

Motsi Ba Tare Da Hysteresis Ba: Tabbatar da cewa matakin ya koma daidai wannan daidaitaccen nanometer a kowane lokaci.

-

Daidaitowar Sauri: Yana da mahimmanci don amfani da na'urorin duba kamar duba E-beam inda ko da ƙaramin "ƙulli" na bearing na injiniya zai ɓata hoton.

-

Tsawon Rai: Tunda babu sassan da ke taɓawa, babu lalacewa kuma babu samar da ƙwayoyin cuta, wanda hakan ya sa suka dace da muhallin tsaftace ɗaki na aji 1.

A ZHHIMG, muna ƙera saman dutse mai faɗi sosai wanda ke aiki a matsayin hanyar jagora ga waɗannan bearings na iska. Domin yin aiki daidai, dole ne a haɗa waɗannan saman zuwa faɗin da aka auna a cikin ɓangarorin tsawon haske.

Sauye-sauye a Kayan Aikin Babban Kwandasta na Semiconductor: 2026 da Bayan haka

A yayin da muke ci gaba da shirin shekarar 2026,yanayin kayan aikin jari na semiconductoran siffanta su da "Ginshiƙai Uku": Tsarin daidaitawa, Dorewa, da Kula da Zafi.

-

Tsarin Tsarin Tsarin Modular: OEMs suna neman kayan aikin tushe na "plug-and-play". Maimakon tsara sabon tushe ga kowane kayan aiki, suna amfani da tushe na daidaito na ZHHIMG waɗanda za a iya daidaita su don lithography, metrology, ko etching.

-

Gudanar da Zafi: Yayin da tushen hasken EUV (Extreme Ultraviolet) ke samar da zafi mai yawa, tushen injin dole ne ya zama babban wurin nutsar da zafi. Muna haɗa hanyoyin sanyaya masu rikitarwa kai tsaye zuwa cikin abubuwan da ke cikin ma'adinai da granite don kiyaye tarin $<0.01^\circ\text{C}$.

-

Dacewar Injin Tsaftacewa: Da zarar an ƙara yawan hanyoyin da ake amfani da su zuwa yanayin da ke da iskar gas mai yawa, kayan da ake amfani da su dole ne su kasance ba su da iskar gas mai fita. Tsarin sarrafa granite da yumbu na musamman yana tabbatar da cewa ingancin injin ɗin ba zai taɓa lalacewa ta hanyar tushen ginin ba.

Haɗin gwiwa da dabarun ZHHIMG

ZHHIMG ba wai kawai masana'antar kayan aiki ba ce; mu abokin tarayya ne mai mahimmanci a cikin sarkar samar da kayayyaki ta hanyar sarrafa motsi. Cibiyarmu a China tana aiki tare da ƙungiyoyin injiniya a Silicon Valley da Eindhoven don magance ƙalubalen kwanciyar hankali mafi wahala a masana'antar.

Ta hanyar amfani da dabarun yin lapping namu na musamman da kuma fahimtarmu sosai game dadabarun rage girgiza, muna ba abokan cinikinmu damar tura iyakokin Dokar Moore. Ko kuna haɓaka kayan aikin ALD (Atomic Layer Deposition) na zamani ko kuma na'urar bincike mai sauri, tushen ya fara ne da ZHHIMG.

Kammalawa

Juyin halittar masana'antar semiconductor tsere ne da ya saba wa dokokin kimiyyar lissafi. Yayin da masana'antar ke ci gaba da tafiya zuwa 2026, mayar da hankali kan daidaiton ɗaukar iska da kuma damping mai zurfi zai ƙara ƙaruwa. Ci gaba da waɗannan yanayin yana buƙatar tushe—a zahiri da kuma a alamance—wanda aka gina akan ƙwarewa da kirkire-kirkire.

Lokacin Saƙo: Janairu-26-2026