A fannin da ake auna tsayi da inci miliyan ɗaya kuma daidaito shine kawai mizani - yanayi mai wahala wanda ke jagorantar kera ZHHIMG® - akwai kayan aiki ɗaya da ke mulki mafi girma: Gauge Block. An san shi a duk duniya a matsayin Jo Blocks (bayan wanda ya ƙirƙira shi), ma'aunin zamewa, ko tubalan Hoke, waɗannan ƙarfe ko yumbu da aka niƙa da kyau da aka goge su sune ginshiƙin dukkan ma'aunin aunawa. Ba wai kawai kayan aiki ba ne; su ne ainihin siffa ta wani takamaiman tsayi, suna aiki a matsayin maƙasudin ma'auni don daidaita komai daga micrometers da calipers zuwa sandunan sine da alamun dial a cikin kowace babbar masana'antu.

Juyin Juya Halin da Aka Yi: Tarihin Jo Block

Kafin shekarar 1896, wuraren aikin injiniya sun dogara ne akan kayan aikin aunawa na musamman na shaguna—ma'aunin da aka tsara musamman da kuma duba "Tafi/Babu-Tafi". Duk da cewa wannan tsarin yana aiki, bai da muhimmin sashi na daidaiton duniya baki ɗaya.

Wani ƙwararren masanin injiniya ɗan ƙasar Sweden Carl Edvard Johansson ne ya gabatar da wannan ra'ayi mai canza yanayin wasa a shekarar 1896. Ra'ayin Johansson na juyin juya hali shine ƙirƙirar daidaitattun tsayin da aka tsara daidai gwargwado wanda za a iya haɗa shi ba tare da wata matsala ba. Wannan sabon abu yana nufin cewa za a iya haɗa ƙaramin saitin tubalan da aka ƙera da kyau don cimma dubban tsayi daban-daban masu daidaito - sassaucin da ba a taɓa gani ba a da. Tubalan ma'aunin Johansson sun daidaita ma'aunin tsayin da ya dace ga duniyar masana'antu.

Sihiri na Mannewa: Fahimtar "Wringing"

Mafi kyawun fasalin tubalin ma'auni shine ikonsa na mannewa da wani tubali mai ƙarancin kuskure. Wannan lamari ana kiransa wringing. Ana samunsa ta hanyar zame tubalan biyu tare, wanda ke sa saman su na microscopic su haɗu da kyau, wanda a zahiri yana kawar da duk wani gibin iska da kuma rage gudummawar haɗin gwiwa ga kuskuren gaba ɗaya.

Wannan keɓantaccen abu shine abin da ke ba tubalan ma'auni amfaninsu mai ban mamaki. Misali, ta hanyar amfani da tubalan uku kawai daga saitin da aka saba, mutum zai iya cimma tsayi daban-daban dubu - misali, daga 3.000 mm zuwa 3.999 mm a cikin ƙaruwar 0.001 mm. Wannan dabara ce mai zurfi ta injiniya wacce ke sa su zama dole.

Matakai Huɗu Don Cikakkiyar Ƙirƙira

Cimma wannan haɗin kai na daidaito ƙwarewa ce mai matakai huɗu:

- Tsaftacewa ta Farko: Fara da goge tubalan ma'auni a hankali a kan kushin gyaran fuska mai mai.

- Cire Mai: Na gaba, goge tubalan a kan busasshen kushin don cire duk wani mai da ya wuce kima, sai kawai a bar ƙaramin fim.

- Tsarin Giciye: Sanya tubali ɗaya a tsaye a kan ɗayan kuma a matse matsakaicin matsin lamba yayin da ake zame su tare har sai sun yi giciye.

- Daidaitawa: A ƙarshe, juya tubalan har sai sun daidaita daidai, a kulle su cikin tari mai ƙarfi da daidaito.

Wannan dabarar da aka yi a hankali ta nuna wajibcin tsafta, matsin lamba mai sarrafawa, da daidaiton daidaito don cimma haɗin da ake buƙata don aikin metrology. Nasarar wannan mannewa an ayyana ta a hukumance a matsayin "ƙwanƙwasawa," wanda ke buƙatar ƙarewar saman microinci 1 0.025 μm m) AA ko mafi kyau, da kuma faɗin da ya kai aƙalla 5 μin (0.13 μm).

Mafi Kyawun Ayyuka: Kare Tsarin Tsawon Ku

Saboda tsananin daidaiton su, tubalan ma'aunin suna buƙatar kulawa wajen sarrafawa da adanawa. Ƙwararru sun fahimci cewa tsawon rai da daidaiton saitin ya dogara ne gaba ɗaya akan bin ƙa'idodi mafi kyau:

- Rigakafin Tsatsa: Nan da nan bayan an yi amfani da shi, dole ne a sake shafa mai ko a shafa masa mai. Tsatsa ita ce babbar maƙiyin daidaiton girma, kuma sakaci da wannan matakin zai lalata daidaiton saman da sauri.

- Kulawa: Kullum rike tubalan a gefensu, ba tare da taɓa saman aunawa masu mahimmanci ba. Zafin jiki da man fata suna komawa zuwa tubalan, wanda ke haifar da faɗaɗa na ɗan lokaci da kuma tsatsa ta dindindin akan lokaci.

- Kula da Zafin Jiki: Tubalan ma'aunin sun fi daidai idan aka auna su a zafin jiki na duniya da aka ƙayyade na 20℃ (68°F). Duk wani ma'auni da aka yi a wajen wannan muhallin da aka sarrafa yana buƙatar diyya ta zafi.

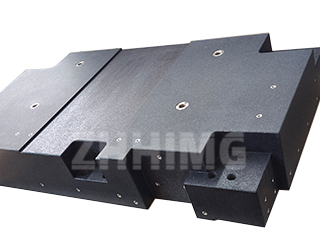

Kammalawa: Tsarin ZHHIMG® da aka gina

Tubalan Gauge sune jaruman da ba a taɓa jin su ba waɗanda suka tabbatar da duniyar kera daidai gwargwado. Su ne wurin da ZHHIMG® ke daidaita kayan aikin aunawa na zamani, yana tabbatar da cewa kayan aikinmu na granite, yumbu, da ƙarfe sun cimma juriyar micrometer da nanometer da ake buƙata ga injunan da suka fi ci gaba a duniya. Ta hanyar girmama tarihi da bin mafi kyawun hanyoyin waɗannan kayan aikin da ba su da mahimmanci, muna goyon bayan daidaitaccen ma'aunin da ke haifar da ci gaban fasaha.

Lokacin Saƙo: Nuwamba-05-2025