A cikin yanayin ci gaba mai sauri na masana'antu na zamani, daidaito ya kasance babban yanki. A yau, an saita wani sabon ƙirƙira don sake fasalta ƙa'idodin masana'antu: Tsarin Gantry na Precision Marble Three-Axis, wani abin mamaki na injiniya wanda ya haɗu da kwanciyar hankali na dutse na halitta tare da ƙirar injiniya ta zamani don cimma daidaiton matakin micron da aka yi tunanin ba za a iya cimmawa ba a aikace-aikacen masana'antu.

Kimiyyar da ke Bayan Kwanciyar Hankali

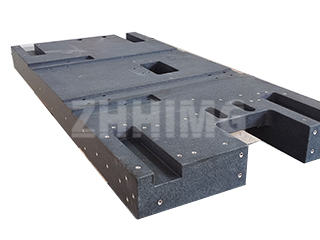

A tsakiyar wannan tsalle-tsalle na fasaha akwai zaɓin abu da ba a zata ba: dutse na halitta. Tushen marmara mai girman 1565 x 1420 x 740 mm na dandamalin ba wai kawai kyawun ƙira bane - mafita ce ta kimiyya ga ƙalubalen da ya daɗe yana fuskanta na kiyaye daidaito a cikin tsarin daidaito mai ƙarfi. "Ƙarancin yawan faɗaɗa zafi na Granite (2.5 x 10^-6 /°C) da halayen damshi na musamman suna ba da tushe wanda ke tsayayya da canjin yanayin zafi da girgizar injina fiye da tsarin ƙarfe na gargajiya," in ji Dr. Emily Chen, babbar injiniyan injiniya a Cibiyar Binciken Injiniya ta Precision.

Wannan fa'idar ta halitta tana fassara kai tsaye zuwa ma'aunin aiki wanda ke juya masana'antu zuwa ga dama. Dandalin ya cimma ±0.8 μm maimaituwa—ma'ana zai iya komawa zuwa kowane matsayi tare da karkacewa ƙasa da tsawon hasken da ake iya gani—da kuma ±1.2 μm daidaiton matsayi bayan diyya, wanda hakan ya kafa sabon ma'auni ga tsarin sarrafa motsi.

Ingancin Injiniya a Motsi

Bayan tushensa mai ƙarfi, ƙirar gantry ta dandamali mai axis uku ta haɗa da sabbin abubuwa da yawa na mallakar dandamali. X-axis yana da tsarin tuƙi biyu wanda ke kawar da nakasar juyawa yayin motsi mai sauri, yayin da X da Y axis duka suna isar da 750 mm na tafiya mai tasiri tare da madaidaiciyar ≤8 μm a cikin jiragen kwance da tsaye. Wannan matakin daidaiton geometric yana tabbatar da cewa ko da hanyoyin 3D masu rikitarwa suna kiyaye daidaiton ƙananan micron.

Ikon motsi na tsarin yana haifar da daidaito mai ban mamaki tsakanin gudu da daidaito. Duk da cewa matsakaicin saurinsa na 1 mm/s na iya zama kamar ƙarami, an inganta shi don aikace-aikacen da ke buƙatar kulawa mai kyau da kuma duba a hankali - inda daidaito ya fi muhimmanci fiye da motsi mai sauri. Akasin haka, ikon hanzarta 2G yana tabbatar da aikin farawa-tsayawa mai amsawa, wanda yake da mahimmanci don kiyaye aiki mai kyau a cikin hanyoyin dubawa daidai.

Tare da ƙarfin kaya na kilogiram 40 da ƙudurin nm 100 (0.0001 mm), dandamalin yana cike gibin da ke tsakanin ƙananan sarrafawa da ƙarfin masana'antu - wani yanayi mai sauƙin amfani wanda ke haifar da babban sha'awa a fannoni daban-daban na masana'antu.

Canza Masana'antu Masu Muhimmanci

Tasirin wannan ci gaban da aka samu ya shafi fannoni daban-daban na fasaha:

A masana'antar semiconductor, inda ko da lahani na sikelin nanometer na iya sa guntu ya zama mara amfani, kwanciyar hankali na dandamalin yana kawo sauyi ga duba wafer da kuma tsarin daidaita hoto. "Muna ganin karuwar gano lahani ta inganta da kashi 37% a gwaje-gwajen farko," in ji Michael Torres, babban injiniyan tsari a wani babban kamfanin kera kayan aikin semiconductor. "Dakatar da girgizar tushen marmara ya kawar da micro-wobble wanda a da ya ɓoye fasalulluka na sub-50 nm."

Kera na'urorin hangen nesa masu inganci wani abu ne mai amfani. Tsarin goge ruwan tabarau da haɗa su waɗanda a da ake buƙatar sa'o'i masu yawa na gyara da hannu yanzu ana iya sarrafa su ta atomatik tare da sanya su a cikin ƙaramin micron na dandamali, wanda ke rage lokacin samarwa yayin da yake inganta daidaiton aikin gani.

A cikin binciken likitanci, dandamalin yana ba da damar samun ci gaba a cikin sarrafa ƙwayoyin halitta guda ɗaya da kuma ɗaukar hoto mai ƙuduri mai girma. Dr. Sarah Johnson ta Sashen Injiniyan Halittu na Stanford ta lura, "Kwanciyar hankali yana ba mu damar ci gaba da mai da hankali kan tsarin ƙwayoyin halitta na tsawon lokaci, tare da ɗaukar hotunan da ke ɓoyewa waɗanda ke bayyana hanyoyin halittu waɗanda kayan aiki suka ɓoye a baya."

Sauran muhimman aikace-aikacen sun haɗa da injunan auna daidaito (CMMs), marufi na microelectronics, da kayan aikin bincike na kimiyya masu ci gaba—dukkan fannoni inda haɗin kai na musamman na dandamali na daidaito, kwanciyar hankali, da ƙarfin kaya ke magance matsalolin fasaha na dogon lokaci.

Makomar Masana'antu Mai Daidaito

Yayin da masana'antu ke ci gaba da ci gaba da ƙoƙarinsu na rage yawan aiki da kuma ƙara yawan aiki, buƙatar tsarin sanyawa mai inganci zai ƙara ƙaruwa. Tsarin Gantry na Precision Marble Three-Axis Gantry ba wai kawai wani ci gaba ne mai girma ba, har ma wani muhimmin sauyi ne a yadda ake cimma daidaito - amfani da kayan halitta tare da injiniyanci mai ci gaba maimakon dogaro da tsarin diyya mai rikitarwa kawai.

Ga masana'antun da ke bin diddigin ƙalubalen Masana'antu 4.0, wannan dandamali yana ba da ɗan haske game da makomar injiniyan daidaito. Makomar ce inda layin da ke tsakanin "daidaitaccen dakin gwaje-gwaje" da "samar da masana'antu" ke ci gaba da ɓacewa, wanda ke ba da damar ƙirƙirar sabbin abubuwa waɗanda za su tsara komai daga na'urorin lantarki na zamani zuwa na'urorin likitanci masu ceton rai.

Kamar yadda wani mai sharhi kan masana'antu ya faɗa: "A duniyar masana'antu masu daidaito, kwanciyar hankali ba wai kawai wani abu bane - shine ginshiƙin da aka gina duk wasu ci gaba a kai. Wannan dandamali ba wai kawai yana ɗaga matsayin ba ne; yana sake gina shi gaba ɗaya."

Lokacin Saƙo: Oktoba-31-2025