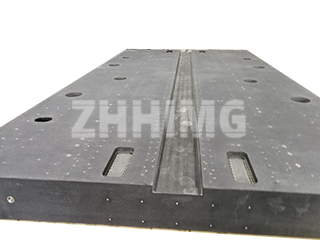

Ingancin kowane tsari na kera ko tsarin kimantawa daidai yana farawa ne da tushen sa. A ZHHIMG®, yayin da sunan mu ya ginu ne akan mafita na Ultra-Precision Granite, mun fahimci muhimmiyar rawar da Faranti na saman ƙarfe na Cast Iron da Faranti na Alamar ke takawa a cikin masana'antu na duniya. Fahimtar yadda ake shigar da su yadda ya kamata, kulawa, da kuma tabbatar da daidaiton waɗannan kayan aikin tunani ba kawai kyakkyawan aiki ba ne - bambanci ne tsakanin tabbatar da inganci da kuma tarkace mai tsada.

Babban Bukatar da ake buƙata: Shigarwa Mai Kyau da Tsarin da Ba a Taɓa Yi Ba

Kafin farantin alamar ƙarfe na siminti ya isar da daidaiton ma'auninsa, dole ne a shigar da shi daidai kuma a daidaita shi. Wannan muhimmin matakin saitin ba wai kawai tsari bane; yana shafar daidaiton tsarin farantin da kuma lanƙwasa. Shigarwa mara kyau - kamar rarraba kaya mara daidai ko daidaita matakin daidai - na iya karya ƙa'idodin masana'antu da kuma canza farantin har abada, wanda hakan zai sa ba za a iya amfani da shi ba. Saboda haka, ma'aikata masu izini ne kawai waɗanda suka sami izini su ɗauki wannan aikin. Keta waɗannan hanyoyin ba wai kawai rashin bin ƙa'ida ba ne amma kuma yana iya lalata tsarin kayan aikin daidai.

Faranti Masu Alaƙa a Tsarin Aiki: Bayanan Nazari

A kowace bita, ana rarraba kayan aiki don takamaiman ayyuka: nassoshi, aunawa, zane kai tsaye, da mannewa. Faranti mai alama shine babban kayan aikin tunani don tsarin rubutu. Rubutu da kansa shine muhimmin aikin fassara takamaiman zane zuwa kayan aiki mara komai ko mara ƙarewa, kafa iyakoki bayyanannu na sarrafawa, wuraren tunani, da layukan gyara masu mahimmanci. Wannan daidaiton rubutu na farko, wanda yawanci ake buƙata ya kasance tsakanin 0.25 mm zuwa 0.5 mm, yana da tasiri kai tsaye da zurfi akan ingancin samfurin ƙarshe.

Domin kiyaye wannan mutunci, dole ne a daidaita farantin kuma a sanya shi cikin aminci, tare da rarraba nauyin daidai gwargwado a duk wuraren tallafi don hana damuwa a tsarin ginin. Masu amfani dole ne su tabbatar da cewa nauyin farantin bai taɓa wuce nauyin da aka kimanta ba don hana lalacewar tsarin ginin, nakasa, da raguwar ingancin aiki. Bugu da ƙari, ya kamata a yi amfani da saman aikin daidai gwargwado don hana lalacewa da lalacewa a yankin, wanda ke tabbatar da tsawon rai.

Duba Faɗi: Kimiyyar Tabbatarwa

Ainihin ma'aunin farantin rubutu shine faɗin farfajiyar aikinsa. Babban hanyar tabbatarwa ita ce Hanyar Tabo. Wannan hanyar tana ƙayyade yawan wuraren hulɗa da ake buƙata a cikin murabba'in 25mm:

- Faranti na Aji 0 da 1: Mafi ƙarancin maki 25.

- Faranti na Aji 2: Mafi ƙarancin maki 20.

- Faranti na Aji 3: Aƙalla maki 12.

Duk da cewa dabarar gargajiya ta "share faranti biyu a kan juna" na iya tabbatar da daidaito da kusancin saman, ba ta tabbatar da lanƙwasa ba. Wannan dabarar na iya haifar da saman biyu masu kyau waɗanda, a zahiri, suna da lanƙwasa mai siffar ƙwallo. Dole ne a tabbatar da daidaiton gaskiya da lanƙwasa ta amfani da hanyoyi masu tsauri. Ana iya auna karkacewar madaidaiciya ta hanyar motsa alamar dial da wurin tallafi tare da ma'aunin madaidaiciya da aka sani, kamar madaidaicin ma'aunin kusurwar dama, a saman farantin. Ga faranti masu mahimmanci, ana amfani da Hanyar Optical Plane ta amfani da interferometry na gani don tabbatar da daidaito a matakin sub-micron.

Kula da Lalacewa: Tabbatar da Tsawon Lokaci da Bin Dokoki

Ingancin farantin alama ana sarrafa shi ta hanyar tsauraran tsare-tsare, kamar ma'aunin JB/T 7974—2000 a masana'antar injina. A lokacin aikin simintin, lahani kamar porosity, ramukan yashi, da ramukan raguwa na iya faruwa. Kula da waɗannan lahani na simintin da ke tattare da su yana da mahimmanci ga tsawon rayuwar farantin. Ga faranti masu daidaiton maki ƙasa da "00," an yarda da wasu gyare-gyare:

- Ƙananan lahani (ƙananan barbashi masu diamita ƙasa da 15mm) za a iya haɗa su da abu ɗaya, muddin ƙarfin toshewar ya yi ƙasa da ƙarfen da ke kewaye.

- Bai kamata saman aikin ya kasance yana da wuraren haɗawa guda huɗu ba, waɗanda suka raba ta da tazara ta akalla $80\text{mm}$.

Bayan lahani na simintin, dole ne saman aikin ya kasance babu tsatsa, ƙaiƙayi, ko ɓarna da ke shafar amfani.

Kulawa don Dawwama Daidaito

Ko kayan aikin da aka yi amfani da shi na Faranti na Alamar ƙarfe na Cast Iron ne ko kuma Faranti na Surface na ZHHIMG® Granite, kulawa abu ne mai sauƙi amma mai mahimmanci. Dole ne a kiyaye saman; idan ba a amfani da shi ba, ya kamata a tsaftace shi sosai kuma a shafa masa mai kariya don hana tsatsa kuma a rufe shi da murfin kariya. Ya kamata a yi amfani da shi koyaushe a cikin yanayi mai sarrafawa, mafi kyau a yanayin zafi na (20± 5)℃, kuma dole ne a guji girgiza sosai. Ta hanyar bin waɗannan ƙa'idodi masu tsauri don shigarwa, amfani, da kulawa, masana'antun za su iya tabbatar da cewa jiragen ruwansu sun kasance daidai, suna kare inganci da amincin samfuransu na ƙarshe.

Lokacin Saƙo: Oktoba-31-2025