Granite wani nau'i ne na dutsen da aka haƙa don tsananin ƙarfinsa, yawa, dorewa, da juriya ga lalata. Amma granite kuma yana da amfani sosai - ba kawai don murabba'ai da rectangles ba! A gaskiya ma, Muna aiki da ƙarfin gwiwa tare da kayan aikin granite da aka ƙera su a cikin siffofi, kusurwoyi, da masu lanƙwasa na kowane bambancin akai-akai-tare da kyakkyawan sakamako.

Ta hanyar aikin mu na fasaha, yanke saman na iya zama na musamman lebur. Waɗannan halayen suna sa granite ya zama abin da ya dace don ƙirƙirar ƙira-ƙira da ƙira na ƙirar injin da abubuwan haɗin metrology. Granite shine:

∎ na'ura

■ Daidai lebur lokacin da aka yanke kuma an gama

■ Tsatsa mai jurewa

■ m

■ dawwama

Abubuwan Granite kuma suna da sauƙin tsaftacewa. Lokacin ƙirƙirar ƙirar al'ada, tabbatar da zaɓar granite don fa'idodinsa mafi girma.

STANDARDS / HIGH WEAR APPLICATIONS

Gilashin da ZHHIMG ke amfani da shi don daidaitattun samfuran farantin mu yana da babban abun ciki na quartz, wanda ke ba da juriya ga lalacewa da lalacewa. Launukan Baƙaƙen mu suna da ƙarancin shayar ruwa, yana rage yuwuwar tsatsawar ma'aunin daidaitattun ku yayin saitawa akan faranti. Launuka na granite da ZHHIMG ke bayarwa suna haifar da ƙarancin haske, wanda ke nufin ƙarancin ido ga mutane masu amfani da faranti. Mun zaɓi nau'ikan granite ɗin mu yayin da muke la'akari da haɓaka yanayin zafi a ƙoƙarin kiyaye wannan yanayin kaɗan.

ABUBUWAN DA AKE YIWA

Lokacin da aikace-aikacenku ya yi kira ga faranti mai siffofi na al'ada, abubuwan da aka saka, ramummuka ko wasu machining, za ku so ku zaɓi wani abu kamar Black Jinan Black. Wannan abu na halitta yana ba da ƙoshin ƙarfi, kyakkyawan damping na girgiza, da ingantattun injina.

Yana da mahimmanci a lura cewa launi kawai ba alama ce ta halayen jiki na dutse ba. Gabaɗaya, launi na granite yana da alaƙa kai tsaye da kasancewar ko rashi na ma'adanai, wanda bazai da tasiri akan halayen da ke yin kayan faranti mai kyau. Akwai ruwan hoda, launin toka, da baƙar fata waɗanda ke da kyau ga faranti na saman, da kuma baƙar fata, launin toka, da ruwan hoda waɗanda ba su dace da ainihin aikace-aikacen ba. Abubuwan da ke da mahimmanci na granite, kamar yadda suka shafi amfani da shi azaman kayan farantin karfe, ba su da alaƙa da launi, kuma sune kamar haka:

∎ Tauri (juyawa a ƙarƙashin kaya - Modulus of Elasticity ya nuna)

■ Tauri

Yawan yawa

■ Sanya juriya

■ Kwanciyar hankali

■ Rashin ƙarfi

Mun gwada kayan granite da yawa kuma mun kwatanta waɗannan kayan. A ƙarshe mun sami sakamakon, Jinan black granite shine mafi kyawun kayan da muka taɓa sani. Bakar granite na Indiya da granite na Afirka ta Kudu suna kama da Jinan Black Granite, amma kayan jikinsu bai kai Jinan Black Granite ba. ZHHIMG zai ci gaba da neman ƙarin kayan granite a cikin duniya kuma ya kwatanta halayensu na zahiri.

Don ƙarin magana game da granite wanda ya dace don aikinku, da fatan za a tuntuɓe muinfo@zhhimg.com.

Masana'antun daban-daban suna amfani da ma'auni daban-daban. Akwai mizanai da yawa a duniya.

DIN Standard, ASME B89.3.7-2013 ko Ƙididdigar Tarayya GGG-P-463c (Granite Surface Plates) da sauransu a matsayin tushen ƙayyadaddun su.

Kuma za mu iya kera farantin gwajin daidaitaccen granite bisa ga bukatun ku. Barka da zuwa tuntube mu idan kuna son ƙarin bayani game da ƙarin ƙa'idodi.

Ana iya la'akari da kwanciyar hankali kamar yadda duk maki a saman yana ƙunshe a cikin jiragen sama guda biyu masu kama da juna, jirgin ƙasa da kuma rufin rufin. Ma'auni na nisa tsakanin jiragen shine gaba ɗaya lebur na saman. Wannan ma'aunin kwanciyar hankali yawanci yana ɗaukar juriya kuma yana iya haɗawa da ƙima.

Misali, an ayyana haƙƙoƙin ɗabi'a na ma'auni guda uku a cikin ƙayyadaddun tarayya kamar yadda aka ƙaddara ta wannan dabara:

■ Matsayin dakin gwaje-gwaje AA = (40 + murabba'in murabba'i/25) x .000001" (bangare)

■ Matsayin Dubawa A = Matsayin dakin gwaje-gwaje AA x 2

■ Dakin Kayan aiki Grade B = Matsayin dakin gwaje-gwaje AA x 4.

Don daidaitattun faranti masu girma dabam, muna ba da garantin tolerances flatness wanda ya wuce buƙatun wannan ƙayyadaddun. Bugu da ƙari, flatness, ASME B89.3.7-2013 & Tarayya Specification GGG-P-463c adireshin batutuwa ciki har da: maimaita ma'auni daidaito, kayan Properties na surface farantin granites, surface gama, goyon bayan batu wuri, stiffness, m hanyoyin dubawa, shigarwa na Threaded abun da ake sakawa, da dai sauransu.

ZHHIMG granite faranti da faranti duba granite sun cika ko wuce duk buƙatun da aka tsara a cikin wannan ƙayyadaddun bayanai. A halin yanzu, babu ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun faranti na kusurwar granite, daidaici, ko murabba'ai na manyan.

Kuma zaku iya samun dabarar wasu ma'auni a cikiSAUKARWA.

Na farko, yana da mahimmanci a kiyaye farantin karfe. Kurar ƙurar ƙura ta iska ita ce mafi girman tushen lalacewa da tsagewa a kan faranti, yayin da take ƙoƙarin haɗawa a cikin guntuwar aiki da wuraren tuntuɓar gages. Na biyu, rufe farantinka don kare shi daga kura da lalacewa. Za a iya tsawaita rayuwar sawa ta hanyar rufe farantin lokacin da ba a yi amfani da ita ba, ta hanyar jujjuya farantin lokaci-lokaci ta yadda yanki ɗaya ba zai sami yawan amfani da shi ba, da kuma maye gurbin karfen karfe akan ma'auni tare da pads na carbide. Hakanan, guje wa sanya abinci ko abubuwan sha masu laushi a kan farantin. Lura cewa yawancin abubuwan sha masu laushi sun ƙunshi ko dai carbonic ko phosphoric acid, wanda zai iya narkar da ma'adanai masu laushi kuma ya bar ƙananan ramuka a saman.

Wannan ya danganta da yadda ake amfani da farantin. Idan za ta yiwu, muna ba da shawarar tsaftace farantin a farkon rana (ko aikin aiki) da kuma a ƙarshen. Idan farantin ya zama ƙazanta, musamman tare da ruwa mai mai ko mai ɗaki, mai yiwuwa a tsaftace shi nan da nan.

Tsaftace farantin akai-akai da ruwa ko ZHHIMG Mai tsabtace faranti mara ruwa. Zaɓin mafita na tsaftacewa yana da mahimmanci. Idan aka yi amfani da wani abu mai sauƙi (acetone, lacquer thinner, barasa, da dai sauransu) ƙawancen zai yi sanyi a saman, kuma ya karkatar da shi. A wannan yanayin, wajibi ne don ƙyale farantin ya daidaita kafin amfani da shi ko kuskuren auna zai faru.

Adadin lokacin da ake buƙatar farantin don daidaitawa zai bambanta da girman farantin, da adadin sanyi. Sa'a guda ya kamata ya isa ga ƙananan faranti. Ana iya buƙatar sa'o'i biyu don manyan faranti. Idan aka yi amfani da na'urar tsabtace ruwa, za a kuma sami ɗan sanyi mai fitar da iska.

Farantin kuma zai riƙe ruwan, kuma wannan na iya haifar da tsatsawar sassan ƙarfe a cikin hulɗa da saman. Wasu masu tsaftacewa kuma za su bar ragi mai ɗanko bayan sun bushe, wanda zai jawo ƙurar iska, kuma a zahiri ƙara lalacewa, maimakon rage shi.

Wannan ya dogara da amfani da farantin karfe da muhalli. Muna ba da shawarar cewa sabon faranti ko madaidaicin kayan haɗe-haɗe na granite ya sami cikakken gyarawa cikin shekara ɗaya na siyan. Idan farantin granite zai ga amfani mai nauyi, yana iya zama da kyau a rage wannan tazara zuwa watanni shida. Binciken wata-wata don maimaita kurakuran aunawa ta amfani da matakin Lantarki, ko makamancin na'ura zai nuna duk wani tabo mai tasowa kuma yana ɗaukar mintuna kaɗan kawai don aiwatarwa. Bayan an tantance sakamakon sakewa na farko, za a iya tsawaita ko taqaitaccen tazarar kamar yadda aka ba da izini ko buƙatun tsarin ingancin ku na ciki.

Za mu iya ba da sabis don taimaka muku duba da daidaita farantin dutsen ku.

Akwai dalilai da yawa masu yiwuwa don bambance-bambance tsakanin calibrations:

- An wanke saman da bayani mai zafi ko sanyi kafin a daidaita shi, kuma ba a ba da izinin isasshen lokaci don daidaitawa ba

- Ana goyan bayan farantin da bai dace ba

- Canjin yanayin zafi

- Zane-zane

- Hasken rana kai tsaye ko wani zafi mai haskakawa a saman farantin. Tabbatar cewa hasken sama baya dumama saman

- Bambance-bambance a cikin madaidaicin zafin jiki tsakanin hunturu da lokacin rani (Idan ta yiwu, ku san yanayin zafin jiki a tsaye a lokacin da ake yin gyaran fuska.)

- Ba a ba da izinin farantin isashen lokaci don daidaitawa bayan jigilar kaya

- Yin amfani da kayan aikin dubawa mara kyau ko amfani da kayan aikin da ba a daidaita su ba

- Canjin yanayi sakamakon lalacewa

Ga masana'antu da yawa, ɗakunan dubawa da dakunan gwaje-gwaje, madaidaicin faranti na granite an dogara da su azaman tushen ma'auni daidai. Domin kowane ma'aunin linzamin kwamfuta ya dogara da ingantaccen wurin tunani wanda aka ɗauko ma'auni na ƙarshe, faranti na saman suna samar da mafi kyawun jirgin sama don duba aiki da shimfidar wuri kafin mashin ɗin. Hakanan madaidaitan tushe ne don yin ma'aunin tsayi da filaye mai gagewa. Bugu da ari, babban mataki na flatness, kwanciyar hankali, gabaɗaya inganci da aikin aiki ya sa su zama zaɓi mai kyau don hawa nagartattun injiniyoyi, lantarki da tsarin gaging na gani. Ga kowane ɗayan waɗannan matakan aunawa, yana da mahimmanci a kiyaye faranti na saman ƙasa.

Maimaita Ma'auni da Lalacewa

Dukansu flatness da maimaita ma'auni suna da mahimmanci don tabbatar da daidaitaccen wuri. Ana iya la'akari da kwanciyar hankali kamar yadda duk maki a saman yana ƙunshe a cikin jiragen sama guda biyu masu kama da juna, jirgin ƙasa da kuma rufin rufin. Ma'auni na nisa tsakanin jiragen shine gaba ɗaya lebur na saman. Wannan ma'aunin kwanciyar hankali yawanci yana ɗaukar juriya kuma yana iya haɗawa da ƙima.

An ayyana haƙƙoƙin daɗaɗɗa don ma'auni guda uku a cikin ƙayyadaddun tarayya kamar yadda aka ƙaddara ta wannan dabara:

DIN Standard, GB Standard, ASME Standard, JJS ma'auni ... ƙasa daban-daban tare da matsayi daban-daban ...

Ƙarin cikakkun bayanai game da ma'auni.

Baya ga flatness, dole ne a tabbatar da maimaitawa. Ma'auni mai maimaitawa shine ma'auni na wurare masu laushi na gida. Ma'auni ne da aka ɗauka a ko'ina a saman faranti wanda zai maimaita cikin haƙurin da aka bayyana. Sarrafa shimfidar wuri na gida zuwa mafi tsananin juriya fiye da shimfidar wuri gabaɗaya yana ba da garantin canji a hankali a cikin bayanin martabar shimfidar ƙasa, ta haka rage kurakuran gida.

Don tabbatar da farantin saman ya dace da duka biyun da kuma maimaita ƙayyadaddun ma'auni, masana'antun faranti na granite yakamata suyi amfani da Ƙayyadaddun Tarayya GGG-P-463c azaman tushen ƙayyadaddun su. Wannan daidaitaccen adireshi yana maimaita daidaiton aunawa, kayan kayan kayan granite farantin, ƙarewar saman, wurin goyan baya, taurin kai, hanyoyin dubawa da shigarwa na abubuwan da aka saka.

Duban Sahihancin Farantin

Ta bin ƴan sauƙi jagororin, zuba jari a cikin farantin granite ya kamata ya wuce shekaru masu yawa. Dangane da amfani da farantin, yanayin shago da daidaiton da ake buƙata, yawan duba daidaiton farantin ya bambanta. Babban ƙa'idar babban yatsan hannu shine sabon faranti don karɓar cikakken sakewa a cikin shekara ɗaya na siyan. Idan ana amfani da farantin akai-akai, yana da kyau a rage wannan tazara zuwa watanni shida.

Kafin farantin saman ya sawa fiye da ƙayyadaddun ƙayyadaddun ƙayyadaddun labulen gabaɗaya, zai nuna sawa ko sawa. Binciken wata-wata don maimaita kurakuran auna ta amfani da maimaita karatun gage zai gano tabo. Maimaita karatun gage babban kayan aiki ne wanda ke gano kuskuren gida kuma ana iya nunawa akan babban ƙararrakin lantarki.

Ingantacciyar shirin dubawa yakamata ya haɗa da cak na yau da kullun tare da autocollimator, yana ba da ainihin daidaitawa na gabaɗaya flatness wanda za'a iya ganowa zuwa Cibiyar Matsayi da Fasaha ta ƙasa (NIST). Cikakken daidaitawa ta masana'anta ko kamfani mai zaman kansa ya zama dole lokaci zuwa lokaci.

Bambance-bambance Tsakanin Calibrations

A wasu lokuta, ana samun bambance-bambance tsakanin matakan daidaita faranti. Wasu lokuta dalilai kamar canjin yanayi da ke haifar da lalacewa, rashin amfani da kayan aikin dubawa ko amfani da kayan aikin da ba a daidaita su ba na iya yin lissafin waɗannan bambance-bambancen. Abubuwa biyu da suka fi kowa yawa, duk da haka, sune zafin jiki da tallafi.

Ɗaya daga cikin mahimman masu canji shine zafin jiki. Misali, ana iya wanke saman da bayani mai zafi ko sanyi kafin a daidaita kuma ba a ba da isasshen lokaci don daidaitawa ba. Sauran abubuwan da ke haifar da canjin zafin jiki sun haɗa da zazzagewar sanyi ko iska mai zafi, hasken rana kai tsaye, hasken sama ko wasu hanyoyin samun zafi a saman farantin.

Hakanan ana iya samun bambance-bambance a cikin madaidaicin zafin jiki tsakanin hunturu da bazara. A wasu lokuta, ba a ba da izinin farantin isasshen lokaci don daidaitawa bayan jigilar kaya. Yana da kyau a yi rikodin zafin jiki a tsaye a lokacin da ake yin gyare-gyare.

Wani dalili na gama-gari don bambance-bambancen daidaitawa shine farantin da aka goyan baya da kyau. Ya kamata a goyan bayan farantin saman a maki uku, wanda ya dace da 20% na tsayin ciki daga ƙarshen farantin. Ya kamata a sami goyon baya biyu 20% na nisa daga cikin dogayen ɓangarorin, kuma sauran goyon bayan ya kamata a tsakiya.

Maki uku ne kawai za su iya tsayawa da ƙarfi akan komai sai madaidaicin saman. Ƙoƙarin tallafawa farantin a sama da maki uku zai sa farantin ya sami goyon bayansa daga haɗuwa daban-daban na maki uku, wanda ba zai kasance daidai da maki uku da aka tallafa masa a lokacin samarwa ba. Wannan zai gabatar da kurakurai yayin da farantin ke juyawa don dacewa da sabon tsarin tallafi. Yi la'akari da yin amfani da madaidaicin karfe tare da katako mai goyan baya da aka tsara don yin layi tare da madaidaitan wuraren tallafi. Tsaye don wannan dalili gabaɗaya ana samun su daga masana'anta farantin.

Idan farantin yana da goyon baya da kyau, daidaitaccen daidaitawa ya zama dole kawai idan aikace-aikacen ya ƙayyade shi. Matsayi ba lallai ba ne don kiyaye daidaiton farantin da aka goyan baya da kyau.

Tsawaita Rayuwar Plate

Bin wasu ƴan jagorori zai rage lalacewa akan farantin granite kuma a ƙarshe, tsawaita rayuwarsa.

Na farko, yana da mahimmanci a kiyaye farantin karfe. Kurar ƙurar ƙura ta iska yawanci ita ce mafi girman tushen lalacewa da tsagewa akan faranti, saboda tana ƙoƙarin haɗawa a cikin kayan aiki da saman ma'auni.

Hakanan yana da mahimmanci a rufe faranti don kare shi daga ƙura da lalacewa. Za a iya tsawaita rayuwar sawa ta hanyar rufe farantin lokacin da ba a amfani da ita.

Juya farantin lokaci-lokaci don kada yanki ɗaya ya sami amfani da yawa. Har ila yau, ana bada shawara don maye gurbin ginshiƙan tuntuɓar ƙarfe akan ma'auni tare da sandunan carbide.

Ka guji saita abinci ko abin sha a faranti. Yawancin abubuwan sha masu laushi sun ƙunshi ko dai carbonic ko phosphoric acid, wanda zai iya narkar da ma'adanai masu laushi kuma ya bar ƙananan ramuka a saman.

Inda za a Komawa

Lokacin da farantin granite yana buƙatar sake buɗewa, la'akari da ko za a yi wannan sabis ɗin a wurin ko a wurin daidaitawa. Zai fi kyau koyaushe a sake dawo da farantin a masana'anta ko wurin da aka keɓe. Idan, duk da haka, farantin ba a sawa sosai ba, gabaɗaya tsakanin 0.001 inch na haƙurin da ake buƙata, ana iya sake farfado da shi akan rukunin yanar gizon. Idan farantin yana sawa har ya wuce inci 0.001 don haƙuri, ko kuma idan an yi masa mummunan rami ko kuma an yi shi da kyau, to sai a aika shi zuwa masana'anta don niƙa kafin a sake dawowa.

Wurin daidaitawa yana da kayan aiki da saitin masana'anta suna samar da ingantattun yanayi don daidaita faranti mai kyau da sake yin aiki idan ya cancanta.

Yakamata a yi taka tsantsan wajen zabar gyare-gyaren kan layi da gyare-gyaren gyare-gyare. Nemi izini kuma tabbatar da kayan aikin da ma'aikacin zai yi amfani da shi yana da ma'auni mai iya ganowa. Kwarewa kuma muhimmin abu ne, saboda ana ɗaukar shekaru masu yawa don koyon yadda ake daidaita madaidaicin granite.

Ma'auni masu mahimmanci suna farawa da madaidaicin farantin granite a matsayin tushe. Ta hanyar tabbatar da abin dogara ta hanyar amfani da farantin da aka daidaita daidai, masana'antun suna da ɗaya daga cikin mahimman kayan aikin don ma'auni masu dogara da mafi kyawun sassa.Q

Jerin abubuwan dubawa don Bambance-bambancen Calibration

1. An wanke saman tare da bayani mai zafi ko sanyi kafin a daidaita shi kuma ba a yarda da isasshen lokaci don daidaitawa ba.

2. An goyan bayan farantin ba daidai ba.

3. Canjin yanayi.

4. Zane-zane.

5. Hasken rana kai tsaye ko wani zafi mai haskakawa a saman farantin. Tabbatar cewa hasken sama baya dumama saman.

6. Bambance-bambance a cikin yanayin zafin jiki na tsaye tsakanin hunturu da lokacin rani. Idan za ta yiwu, san yanayin zafi a tsaye a lokacin da ake yin gyare-gyare.

7. Ba a yarda da farantin isashen lokaci don daidaitawa bayan jigilar kaya.

8. Yin amfani da kayan bincike mara kyau ko amfani da kayan aikin da ba a daidaita su ba.

9. Canjin yanayi sakamakon lalacewa.

Tips na Fasaha

- Domin kowane ma'aunin linzamin kwamfuta ya dogara da ingantaccen wurin tunani wanda aka ɗauko ma'auni na ƙarshe, faranti na saman suna samar da mafi kyawun jirgin sama don duba aiki da shimfidar wuri kafin mashin ɗin.

- Sarrafa shimfidar wuri na gida zuwa mafi tsananin juriya fiye da shimfidar wuri gabaɗaya yana ba da garantin canji a hankali a cikin bayanin martabar shimfidar ƙasa, ta haka rage kurakuran gida.

- Ingantacciyar shirin dubawa yakamata ya haɗa da dubawa akai-akai tare da na'ura mai sarrafa kansa, yana samar da ainihin daidaitaccen daidaituwa na gabaɗaya wanda za'a iya ganowa ga Hukumar Binciken Ƙasa.

Daga cikin nau'o'in ma'adinai da suka hada da granite, fiye da 90% sune feldspar da quartz, wanda feldspar ya fi yawa. Feldspar sau da yawa fari, launin toka, da nama-ja, kuma ma'adini ba shi da launi ko launin toka, wanda ya zama ainihin launi na granite. Feldspar da quartz ma'adanai ne masu wuya, kuma yana da wuya a motsa da wuka na karfe. Amma ga wuraren duhu a cikin granite, galibi baki mica, akwai wasu ma'adanai. Kodayake biotite yana da laushi mai laushi, ikonsa na tsayayya da danniya ba shi da rauni, kuma a lokaci guda suna da ƙananan adadin a cikin granite, sau da yawa kasa da 10%. Wannan shine yanayin kayan da granite ke da ƙarfi musamman.

Wani dalilin da ya sa granite ke da ƙarfi shi ne cewa ƙwayoyin ma'adinan sa suna daure da juna kuma suna cikin juna. Matsalolin sau da yawa suna lissafin ƙasa da 1% na jimlar adadin dutsen. Wannan yana ba da granite damar yin tsayayya da matsi mai ƙarfi kuma ba shi da sauƙin shiga ta hanyar danshi.

Abubuwan da aka gyara na Granite an yi su ne da dutse ba tare da tsatsa ba, acid da juriya na alkali, juriya mai kyau da tsawon rayuwar sabis, babu kulawa ta musamman. Ana amfani da madaidaicin abubuwan haɗin Granite a cikin kayan aikin masana'antar injuna. Saboda haka, ana kiran su granite precision components ko granite sassa. Siffofin madaidaicin granite daidai suke da na dandamali na granite. Gabatarwa ga kayan aiki da auna ma'aunin madaidaicin granite: Mashin ingantattun injina da fasaha na ƙirar ƙirar ƙira sune mahimman hanyoyin haɓaka masana'antar masana'antar injin, kuma sun zama alama mai mahimmanci don auna matakin fasaha mai girma. Haɓaka fasahar yankan-baki da masana'antar tsaro ba za a iya raba su da ingantattun mashin ɗin da fasahar kere-kere ba. Abubuwan da aka gyara na Granite na iya zama sumul a cikin ma'auni, ba tare da tsayawa ba. Ma'aunin saman aiki, tsattsauran ra'ayi na gaba ɗaya baya shafar daidaiton ma'auni. Abubuwan Granite suna buƙatar ƙira da samarwa bisa ga buƙatun ɓangaren buƙata.

Filin aikace-aikace:

Kamar yadda muka sani da ƙarin injuna da kayan aiki suna zabar madaidaicin abubuwan granite.

Granite aka gyara ana amfani da tsauri motsi, mikakke Motors, cmm, cnc, Laser inji ...

barkanmu da sake saduwa da mu don ƙarin bayani.

Na'urorin auna ma'aunin Granite da kayan aikin granite an yi su da babban granite na Jinan Black granite. Saboda madaidaicin madaidaicin su, tsawon lokaci, kyakkyawan kwanciyar hankali da juriya na lalata, an ƙara yin amfani da su a cikin binciken samfuran masana'antar zamani da irin wuraren kimiyya kamar sararin samaniyar injina da binciken kimiyya.

Amfani

---- Sau biyu da ƙarfi kamar simintin ƙarfe;

----Ƙananan canje-canje na girma sun kasance saboda canjin yanayin zafi;

----Free daga wringing, don haka babu katsewar aiki;

----Free daga burrs ko protrusions saboda kyakkyawan tsarin hatsi da mannewa maras muhimmanci, wanda ke tabbatar da babban matakin lebur a tsawon rayuwar sabis kuma baya haifar da lalacewa ga wasu sassa ko kayan aiki;

----Aiki mara matsala don amfani da kayan maganadisu;

---- Rayuwa mai tsawo da tsatsa ba tare da tsatsa ba, wanda ke haifar da ƙananan farashin kulawa.

Madaidaicin faranti na saman dutsen ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ma'auni don cimma daidaito kuma ana amfani da su azaman tushe don hawa na'urori na injiniya, lantarki da tsarin gauging na gani.

Wasu daga cikin abubuwan musamman na farantin granite:

Uniformity a Taurin;

Daidaitacce ƙarƙashin yanayin kaya;

Mai shayar da Vibration;

Sauƙin Tsabtace;

Nade Resistant;

Ƙananan Ƙira;

Mara-Tsarki;

Mara Magnetic

Fa'idodin Filayen Sama na Granite

Na farko, da dutsen bayan dogon lokaci na halitta tsufa, uniform tsarin, coefficient m, da ciki danniya gaba daya bace, ba maras kyau, don haka daidaici ne high.

Na biyu, ba za a yi karce ba, ba a ƙarƙashin yanayin zafin jiki akai-akai ba, a cikin zafin jiki kuma zai iya kiyaye daidaiton ma'aunin zafin jiki.

Na uku, ba maganadisu ba, ma'auni na iya zama motsi mai santsi, babu jin daɗi, ba ruwan shi da danshi, an daidaita jirgin.

Hudu, rigidity yana da kyau, taurin yana da girma, juriya na abrasion yana da ƙarfi.

Biyar, ba ji tsoron acid ba, yashwar ruwa na alkaline, ba zai yi tsatsa ba, ba dole ba ne a fenti mai, ba mai sauƙi ga ƙura mai ƙura ba, kiyayewa, mai sauƙin kulawa, tsawon rayuwar sabis.

Me yasa zabar tushe mai granite maimakon simintin ƙarfe na gado?

1. Tushen injin Granite zai iya kiyaye daidaito mafi girma fiye da tushen injin ƙarfe. Tushen injin ƙarfe na simintin gyare-gyare yana da sauƙin shafar zafin jiki da zafi amma ginin injin granite ba zai yi ba;

2. Tare da girman girman ginin injin granite da simintin ƙarfe na ƙarfe, ginin injin granite ya fi tsada fiye da simintin ƙarfe;

3. Tushen injin granite na musamman ya fi sauƙin gamawa fiye da ginin injin ƙarfe.

Faranti na Granite manyan kayan aikin bincike ne a duk faɗin ƙasar. Ƙimar da aka daidaita, mai faɗi sosai na farantin saman yana bawa masu duba damar amfani da su azaman madogaran binciken sashe da daidaita kayan aiki. Idan ba tare da kwanciyar hankali da ke tattare da faranti na sama ba, yawancin ɓangarorin da aka yarda da su a fagage daban-daban na fasaha da na likitanci za su fi wahala, idan ba zai yiwu ba, kera daidai. Tabbas, don amfani da shingen granite don daidaitawa da kuma duba wasu kayan aiki da kayan aiki, dole ne a kimanta daidaiton granite kanta. Masu amfani za su iya daidaita farantin granite don tabbatar da daidaitonsa.

Tsaftace farantin granite kafin daidaitawa. Zuba karamin adadin farantin karfe mai tsabta a kan mai tsabta mai laushi mai laushi kuma shafa saman granite. Nan da nan ya bushe mai tsabta daga farantin saman da busasshen zane. Kada ka ƙyale ruwan tsaftacewa ya bushe.

Sanya ma'aunin ma'auni mai maimaitawa a tsakiyar farantin granite.

Zero ma'aunin maimaitawa zuwa saman farantin granite.

Matsar da ma'aunin a hankali a fadin saman granite. Duba ma'aunin ma'aunin kuma yi rikodin kololuwar kowane bambancin tsayi yayin da kuke matsar da kayan aiki a kan farantin.

Kwatanta bambance-bambancen lebur a saman farantin tare da juriya don farantin saman ku, wanda ya bambanta dangane da girman farantin da madaidaicin matakin granite. Tuntuɓi ƙayyadaddun bayanai na tarayya GGG-P-463c (duba albarkatu) don tantance idan farantin ku ya cika buƙatun ƙira don girmansa da darajar sa. Bambance-bambancen da ke tsakanin madaidaicin madaidaicin farantin da mafi ƙasƙanci akan farantin shine ma'aunin sa.

Bincika cewa mafi girman bambancin zurfin da ke saman farantin ya faɗi cikin ƙayyadaddun ƙayyadaddun maimaitawa don farantin wannan girman da darajar. Tuntuɓi ƙayyadaddun bayanai na tarayya GGG-P-463c (duba albarkatun) don tantance idan farantin ku ya cika buƙatun maimaitawa don girmansa. Karɓar farantin saman idan ko da aya ɗaya ta gaza buƙatun maimaitawa.

Dakatar da amfani da farantin dutsen da ya kasa cika buƙatun tarayya. Mayar da farantin zuwa ga masana'anta ko ga kamfanin ƙorafi don a sake goge katangar don saduwa da ƙayyadaddun bayanai.

Tukwici

Yi gyare-gyare na yau da kullun aƙalla sau ɗaya a shekara, kodayake faranti na granite da ke ganin amfani mai nauyi ya kamata a daidaita su akai-akai.

Na yau da kullun, ƙididdige ƙididdigewa a cikin masana'antu ko wuraren dubawa ana gudanar da su ta hanyar tabbatar da inganci ko mai siyar da sabis na daidaitawa na waje, kodayake kowa na iya amfani da ma'aunin ma'aunin maimaitawa don bincika farantin ƙasa kafin amfani.

Tarihin Farkon Farkon Faranti

Kafin yakin duniya na biyu, masana'antun sun yi amfani da faranti na saman saman karfe don duba girman sassa. A lokacin yakin duniya na biyu bukatar karfe ya karu sosai, kuma an narkar da faranti da yawa na Karfe. Ana buƙatar maye gurbin, kuma Granite ya zama kayan da aka zaɓa saboda mafi girman halayen sa.

Fa'idodi da yawa na granite akan karfe sun bayyana. Granite ya fi wuya, kodayake ya fi karye kuma yana ƙarƙashin tsinke. Kuna iya jujjuya Granite zuwa mafi girman laushi da sauri fiye da ƙarfe. Granite kuma yana da kyawawan kaddarorin ƙaramar haɓakar zafi idan aka kwatanta da karfe. Bugu da ari, idan farantin karfe yana buƙatar gyara, sai an goge shi da hannu ta hannun masu sana'a waɗanda kuma suka yi amfani da ƙwarewarsu wajen sake gina injin.

A matsayin bayanin kula, har yanzu ana amfani da wasu faranti saman saman Karfe.

Halayen Ma'auni na Granite Plates

Granite wani dutse ne mai ban tsoro wanda aka samo shi ta hanyar fashewar volcanic. Idan aka kwatanta, marmara shine dutsen ƙasa metamorphosed. Don amfani da metrology, granite da aka zaɓa ya kamata ya dace da takamaiman buƙatun da aka tsara a cikin ƙayyadaddun ƙayyadaddun tarayya GGG-P-463c, daga yanzu ana kiransa Fed Specs, kuma musamman, Sashe na 3.1 3.1 Daga cikin Feda Specs, granite ya kamata ya zama mai kyau zuwa rubutu mai matsakaici.

Granite abu ne mai wuyar gaske, amma taurinsa ya bambanta saboda dalilai da yawa. Gogaggen masanin farantin karfe na iya ƙididdige taurin ta launin sa wanda ke nuni da abun cikin sa na quartz. Taurin Granite dukiya ce da aka ayyana a wani ɓangare ta adadin abun ciki na quartz da rashin mica. Jajaye da ruwan hoda granites sun kasance sun fi wuya, launin toka suna da matsakaici, kuma baƙar fata sun fi laushi.

Ana amfani da Modulus na Matasa na Ƙarfafawa don bayyana sassauci ko nuni na taurin dutse. Matsakaicin granite ruwan hoda yana da maki 3-5 akan sikelin, launin toka maki 5-7 sannan baƙar fata maki 7-10. Karami lambar, da wuya da granite oyan zama. Girman lambar, mafi sauƙi kuma mafi sauƙi granite shine. Yana da mahimmanci a san taurin Granite lokacin zabar kauri da ake buƙata don ma'aunin haƙuri da nauyin sassa da ma'aunin da aka sanya akansa.

A zamanin d ¯ a lokacin da akwai masana injiniyoyi na gaske, waɗanda aka sani da litattafan tebur ɗin su a cikin aljihun rigar su, an ɗauki baƙar fata granite a matsayin "Mafi Kyawun." Mafi kyawun da aka bayyana azaman nau'in da ya ba da mafi yawan juriya don sawa ko ya fi wahala. Ɗaya daga cikin koma baya shine cewa granites masu wuya suna yin guntu ko ding sauƙi. Masana injiniyoyi sun gamsu cewa baƙar fata shine mafi kyawun abin da wasu masana'antun na granite mai ruwan hoda suka yi musu launin baki.

Ni da kaina na ga faranti da aka jefar da shi daga kan mazugi lokacin da aka motsa daga wurin ajiya. Farantin ya bugi falon ya raba biyu yana bayyana ainihin kalar hoda. Yi hankali idan kuna shirin siyan granite baki daga China. Muna ba da shawarar ku ɓata kuɗin ku ta wata hanya dabam. Farantin granite zai iya bambanta a cikin taurin kansa. Gilashin ma'adini na iya zama da wahala fiye da sauran farantin karfe. Layer na baƙar fata gabbro na iya sa yanki ya fi laushi. ƙwararrun ƙwararrun ƙwararrun ƙwararrun injinan gyaran faranti sun san yadda ake sarrafa waɗannan wurare masu laushi.

Darajojin Filayen Sama

Akwai nau'ikan faranti guda huɗu. Matsayin dakin gwaje-gwaje AA da A, Binciken ɗaki Grade B, kuma na huɗu shine Grade Workshop. Grade's AA da A sune mafi ƙanƙanta tare da jurewar kwanciyar hankali fiye da 0.00001 a cikin farantin AA na Grade. Makin bita kasancewar mafi ƙanƙanta kuma kamar yadda sunan ke nunawa, an yi nufin amfani da su a ɗakunan kayan aiki. Inda a matsayin Grade AA, Grade A da Grade B an yi niyya don amfani da su a cikin binciken bincike ko kula da ingancin inganci.

PGwajin roper Don Gyaran Farantin Sama

A koyaushe ina gaya wa abokan cinikina cewa zan iya fitar da duk wani ɗan shekara 10 daga cocina in koya musu cikin ƴan kwanaki kaɗan yadda ake gwada faranti. Ba shi da wahala. Yana buƙatar wasu dabaru don aiwatar da aikin cikin sauri, dabarun da mutum ya koya ta lokaci da maimaitawa. Ya kamata in sanar da ku, kuma ba zan iya jaddada isa ba, Fed Spec GGG-P-463c BA hanya ce ta daidaitawa ba! Karin bayani akan haka daga baya.

Daidaitawa na gabaɗaya flatness (Ma'ana Pane) da Maimaituwa (launi na gida) cak ɗin dole ne bisa ga ƙayyadaddun Fed. Iyakar wannan shine tare da ƙananan faranti inda ake buƙatar maimaitawa kawai.

Hakanan, kuma kamar yadda yake da mahimmanci kamar sauran gwaje-gwajen, shine gwajin ma'aunin zafi. (Duba Delta T a ƙasa)

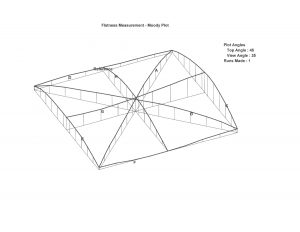

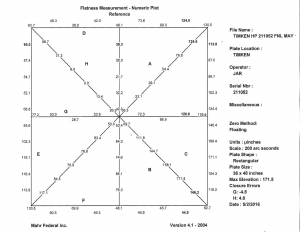

Hoto 1

Gwajin kwanciyar hankali yana da hanyoyin da aka amince da su guda 4. Matakan lantarki, autocollimation, Laser da na'urar da aka sani da mai gano jirgin sama. Muna amfani da matakan lantarki kawai saboda sune mafi inganci kuma hanya mafi sauri saboda dalilai da yawa.

Lasers da autocollimator suna amfani da madaidaicin bishiyar haske azaman tunani. Mutum yana yin ma'auni madaidaiciya na farantin granite ta hanyar kwatanta bambancin nisa tsakanin farantin saman da katakon haske. Ta hanyar ɗaukar madaidaicin haske na haske, buga shi a kan maƙasudin tunani yayin motsa abin da ke nuni zuwa saman farantin, nisa tsakanin katakon da aka fitar da katakon dawowa shine ma'aunin madaidaiciya.

Ga matsalar wannan hanyar. Maƙasudin da tushen suna da rawar jiki, zafin yanayi, ƙasa da lebur ko maƙasudi, gurɓataccen iska, da motsin iska (currents). Duk waɗannan suna ba da ƙarin ɓangarorin kuskure. Bugu da ƙari, gudunmawar kuskuren ma'aikaci daga cak tare da autocollimator ya fi girma.

Gogaggen mai amfani da autocollimator na iya yin ingantattun ma'auni amma har yanzu yana fuskantar matsaloli tare da daidaiton karatun musamman a kan dogon nisa yayin da tunani yakan faɗi ko ya ɗan ruɗe. Har ila yau, ƙasa da madaidaicin manufa da tsayin rana na leƙen asirin ruwan tabarau yana haifar da ƙarin kurakurai.

Na'urar gano jirgin sama wauta ce kawai. Wannan na'urar tana amfani da ɗan madaidaicin ɗanɗano (idan aka kwatanta da madaidaicin haɗaɗɗiyar haske ko hasken Laser) azaman abin nuninta. Ba wai kawai na'urar injiniya tana amfani da ma'aunin nuni kullum na ƙudurin Inci 20 kawai ba amma rashin daidaitaccen mashaya da kayan da ba su da kamanni suna ƙara mahimmanci ga kurakurai a aunawa. A ra'ayinmu, duk da cewa hanyar tana da karɓuwa, babu wani ƙwararren ɗakin bincike da zai taɓa amfani da na'urar gano jirgin sama azaman kayan bincike na ƙarshe.

Matakan lantarki suna amfani da nauyi a matsayin nuni. Daban-daban matakan lantarki ba su tasiri ta hanyar rawar jiki. Suna da ƙuduri mai ƙasa da .1 arc na biyu kuma ma'auni suna da sauri, daidai kuma akwai ƙarancin gudumawar kuskure daga ƙwararren mai aiki. Babu Masu Neman Jirgin Sama ko na'urori masu sarrafa kansu ba su samar da yanayin da aka samar da kwamfuta (Hoto 1) ko makircin isometric (Hoto 2) na saman.

Hoto 2

Daidaitaccen Lalacewa na Gwajin Sama

Daidaitaccen lebur na gwajin saman shine irin wannan muhimmin sashi na wannan takarda da yakamata in sanya shi a farkon. Kamar yadda aka ambata a baya, Fed Spec. GGG-p-463c BA hanya ce ta daidaitawa ba. Yana aiki a matsayin jagora ga abubuwa da yawa na metrology granite wanda mai siyan sa shine kowace Hukumar Gwamnatin Tarayya, kuma hakan ya haɗa da hanyoyin gwaji da juriya ko maki. Idan dan kwangila ya yi iƙirarin sun bi ƙayyadaddun bayanai na Fed, to za a ƙayyade ƙimar ƙimar ta hanyar Moody.

Moody ɗan'uwanmu ne daga baya a cikin 50s wanda ya ƙirƙira hanyar lissafi don tantance fa'ida gabaɗaya da lissafi don daidaita layin da aka gwada, ko sun isa kusanci a cikin jirgin guda ɗaya. Babu wani abu da ya canza. Alamar Allied ta yi ƙoƙarin inganta hanyar ilimin lissafi amma ta kammala da cewa bambance-bambancen kadan ne bai cancanci ƙoƙarin ba.

Idan dan kwangilar faranti yana amfani da matakan lantarki ko Laser, yana amfani da kwamfuta don taimaka masa da lissafin. Ba tare da taimakon kwamfuta ba dole ne mai fasaha na amfani da autocollimation ya lissafta karatun da hannu. A gaskiya, ba su. Yana ɗaukar tsayi da yawa kuma a zahiri yana iya zama da wahala sosai. A cikin gwajin kwanciyar hankali ta amfani da Hanyar Moody, mai fasaha yana gwada layi takwas a cikin tsarin Union Jack don daidaitawa.

Hanyar Moody

Hanyar Moody hanya ce ta lissafi don sanin ko layukan takwas suna kan jirgi ɗaya. In ba haka ba, kawai kuna da layi madaidaiciya 8 waɗanda ƙila ko ba za su kasance a kan ko kusa da jirgi ɗaya ba. Bugu da ari, dan kwangilar da ke da'awar bin Fed Spec, kuma yana amfani da autocollimation, yadolesamar da shafuka takwas na bayanai. Shafi ɗaya na kowane layi da aka duba don tabbatar da gwajinsa, gyara, ko duka biyun. In ba haka ba, dan kwangilar ba shi da masaniyar menene ainihin ƙimar flatness.

Na tabbata idan kana ɗaya daga cikin waɗanda wani ɗan kwangila ya daidaita faranti ta amfani da autocollimation, ba ka taɓa ganin waɗannan shafukan ba! Hoto na 3 misali ne nadaya kawaishafi na takwas wajibi ne don lissafta gaba ɗaya flatness. Alamu ɗaya na wannan jahilci da ƙeta shine idan rahotonku yana da kyawawan lambobi. Misali, 200, 400, 650, da sauransu. Ƙimar da aka lissafta yadda ya kamata ita ce lamba ta gaske. Misali 325.4 u In. Lokacin da dan kwangila ya yi amfani da Hanyar Ƙimar Moody, kuma mai fasaha ya ƙididdige ƙididdiga da hannu, ya kamata ka sami shafuka takwas na ƙididdiga da makircin isometric. Makircin isometric yana nuna tsayin daka daban-daban tare da layukan daban-daban da nawa nisa ke raba wuraren da aka zaɓa.

Hoto 3(Yana ɗaukar shafuka takwas kamar wannan don ƙididdige ƙididdigewa da hannu. Tabbatar cewa ku tambayi dalilin da yasa ba ku samun wannan idan mai kwangila yana amfani da autocollimation!)

Hoto 4

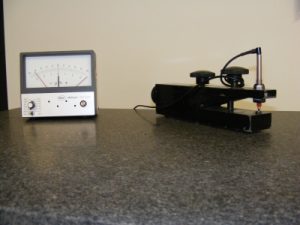

Masu fasaha na Ma'aunin Ma'auni suna amfani da matakan bambanta (Hoto 4) azaman na'urori da aka fi so don auna canje-canjen mintuna a cikin ma'auni daga tashar aunawa zuwa tasha. Matakan suna da ƙuduri zuwa .1 arc seconds (5 u Inci ta amfani da sled 4) suna da ƙarfi sosai, girgiza ba ta shafar su, auna nisa, igiyoyin iska, gajiyar ma'aikaci, gurɓataccen iska ko kowane ɗayan matsalolin da ke cikin wasu na'urori. Ƙara taimakon kwamfuta, kuma aikin ya zama mai saurin sauri, yana samar da filaye da zane-zane na isometric yana tabbatar da tabbatarwa kuma mafi mahimmanci gyara.

Gwajin Maimaituwa Daidai

Maimaita karatu ko maimaitawa shine mafi mahimmancin gwaji. Kayan aikin da muke amfani da su don yin gwajin maimaitawa shine maimaitawa na karantawa, LVDT da amplifier da ake buƙata don ƙarami mai ƙarfi. Mun saita amplifier LVDT zuwa ƙaramin ƙuduri na Inci 10 ko Inci 5 don daidaitattun faranti.

Yin amfani da alamar inji tare da ƙuduri na Inci 20 kawai ba shi da amfani idan kuna ƙoƙarin gwada maimaita buƙatun 35 u Inci. Alamomi suna da rashin tabbas na Inci 40 u! Saitin karatun maimaitawa yana kwaikwayon tsayayyen gage/ɓangare mai tsayi.

Maimaituwa BAI ɗaya bane da kwanciyar hankali gabaɗaya (Ma'anar Jirgin sama). Ina so in yi tunanin maimaitawa a cikin dutsen granite da ake kallo azaman madaidaicin ma'aunin radius.

Hoto 5

Idan kun gwada don maimaita ƙwallon zagaye, to kun nuna radius ɗin ƙwallon bai canza ba. (Mafi kyawun bayanin farantin da aka gyara da kyau yana da siffa mai kambi.) Duk da haka, a bayyane yake cewa ƙwallon ba ta da kyau. To, irin. A kan ɗan gajeren tazara, lebur ne. Tunda yawancin aikin dubawa ya ƙunshi gage mai tsayi kusa da ɓangaren, maimaitawa ya zama mafi mahimmancin kayan farantin granite. Yana da mahimmanci cewa gabaɗayan flatness sai dai idan mai amfani yana duba madaidaiciyar sashi mai tsayi.

Tabbatar cewa dan kwangilar naku yayi gwajin maimaita karatu. Faranti na iya samun maimaita karatu sosai saboda juriya amma har yanzu sun ci jarabawar rashin ƙarfi! Abin mamaki dakin gwaje-gwaje na iya samun izini a gwaji wanda bai haɗa da maimaita gwajin karatu ba. Lab ɗin da ba zai iya gyarawa ba ko kuma ba shi da kyau sosai wajen gyarawa ya fi son yin gwajin ƙima kawai. Lallashi ba ya canzawa sai dai idan kun matsar da farantin.

Maimaita gwajin karatu shine mafi sauƙi don gwadawa amma mafi wahala a samu lokacin yin tsalle. Tabbatar cewa ɗan kwangilar naku zai iya dawo da maimaitawa ba tare da “tasa” saman ko barin raƙuman ruwa a saman ba.

Gwajin Delta T

Wannan gwajin ya ƙunshi auna ainihin zafin dutse a saman samansa da samansa na ƙasa da ƙididdige bambanci, Delta T, don bayar da rahoto kan takaddun shaida.

Yana da mahimmanci a san matsakaicin ƙimar haɓakar haɓakar thermal a cikin granite shine 3.5 uIn/inch/digiri. Yanayin yanayi da tasirin zafi akan farantin granite ba shi da komai. Duk da haka, farantin saman na iya fita daga juriya ko wani lokacin inganta ko da a cikin .3 - .5 digiri F Delta T. Wajibi ne a san idan Delta T yana cikin .12 digiri F na inda bambanci daga karshe calibration.

Hakanan yana da mahimmanci a san cewa faranti na aiki saman yana ƙaura zuwa zafi. Idan saman zafin jiki ya fi zafi fiye da ƙasa, to, saman saman ya tashi. Idan kasa ya fi zafi, wanda ba shi da wuya, to, saman saman ya nutse. Bai isa ga manajan ko mai fasaha ba su san farantin lebur ne kuma ana iya maimaita su a lokacin daidaitawa ko gyara amma abin da Delta T yake a lokacin gwaji na ƙarshe. A cikin mawuyacin yanayi mai amfani zai iya, ta hanyar auna Delta T da kansa, tantance ko faranti ya fita daga juriya saboda kawai bambancin Delta T. Abin farin ciki, granite yana ɗaukar sa'o'i masu yawa ko ma kwanaki don daidaitawa zuwa yanayi. Ƙananan sauye-sauye a yanayin zafi a cikin yini ba zai yi tasiri ba. Saboda waɗannan dalilai, ba mu bayar da rahoton zafin yanayin yanayin yanayi ko zafi ba saboda illar ba su da komai.

Granite Plate Wear

Duk da yake granite yana da wuya fiye da faranti na karfe, granite har yanzu yana tasowa ƙananan wurare a saman. Maimaita motsi na sassa da gages akan farantin saman shine mafi girman tushen lalacewa, musamman idan yanki ɗaya ake amfani dashi koyaushe. Datti da ƙurar niƙa da aka bari su kasance a saman faranti suna haɓaka aikin lalacewa yayin da yake shiga tsakanin sassa ko ma'auni da saman granite. Lokacin motsi sassa da gages a samanta, ƙurar ƙura yawanci shine dalilin ƙarin lalacewa. Na ba da shawarar tsaftacewa akai-akai don rage lalacewa. Mun ga lalacewa ta kan faranti da ke haifar da isar da fakitin UPS na yau da kullun da aka sanya a saman faranti! Waɗancan wuraren da aka keɓance na lalacewa suna shafar karatun gwajin maimaitawa. Guji sawa ta hanyar tsaftacewa akai-akai.

Granite Plate Cleaning

Don tsaftace farantin, yi amfani da rigar tack don cire datti. Kawai danna sauƙaƙa, don kada ku bar ragowar manne. Tufafin da aka yi amfani da shi da kyau yana yin kyakkyawan aiki na ɗaukar ƙura mai niƙa tsakanin tsaftacewa. Kada ku yi aiki a wuri guda. Matsar da saitin ku a kusa da farantin, rarraba lalacewa. Yana da kyau a yi amfani da barasa don tsaftace faranti, amma ku sani cewa yin hakan zai ɗan ɗanyi sanyi sosai. Ruwa tare da ƙaramin adadin sabulu yana da kyau. Masu tsabtace kasuwanci da ake samu irin su Starrett's cleaner suma suna da kyau a yi amfani da su, amma ka tabbata ka sami ragowar sabulun daga saman.

Gyaran Farantin Granite

Ya kamata a bayyana a yanzu mahimmancin tabbatar da cewa ɗan kwangilar farantin ku ya yi ingantaccen aiki. Nau'in labs na "Clearing House" waɗanda ke ba da shirye-shiryen "Yi duka tare da kira ɗaya" da wuya su sami ƙwararren masani wanda zai iya gyarawa. Ko da suna ba da gyare-gyare, ba koyaushe suna da ƙwararren injiniya wanda ke da ƙwarewar da ake buƙata lokacin da farantin saman ba ya da haƙuri.

Idan aka ce faranti ba za a iya gyarawa ba saboda matsanancin lalacewa, kira mu. Mafi mahimmanci za mu iya yin gyara.

Fasahar mu tana yin aikin koyan shekara ɗaya zuwa ɗaya da rabi a ƙarƙashin ƙwararrun ƙwararrun ƙwararrun ƙwararru. Mun ayyana ƙwararren ƙwararren masani a matsayin wanda ya kammala karatunsa kuma yana da ƙarin ƙwarewar shekaru goma a cikin gyaran fuska da gyaran fuska. Mu a Dimensional Gauge muna da Master Technicians guda uku akan ma'aikatan tare da gogewar shekaru sama da 60 a hade. Ɗaya daga cikin Mashawarcin Jagoranmu yana samuwa a kowane lokaci don tallafi da jagora don lokacin da yanayi mai wahala ya taso. Dukkanin ƙwararrun ƙwararrunmu suna da gogewa a cikin gyare-gyaren faranti na kowane girma, daga ƙanana zuwa manya, yanayin muhalli daban-daban, masana'antu daban-daban, da manyan matsalolin lalacewa.

Ƙididdiga na Fed suna da ƙayyadaddun buƙatu na ƙarshe na 16 zuwa 64 Matsakaici Roughness Arithmetic (AA). Mun fi son ƙarewa a cikin kewayon 30-35 AA. Akwai kawai rashin ƙarfi don tabbatar da sassa da gages suna tafiya lafiya kuma kar a manne ko murɗawa a farantin.

Lokacin da muka gyara muna duba farantin don daidaitawa da daidaitawa. Muna amfani da busasshiyar hanyar latsawa, amma idan akwai matsanancin lalacewa da ke buƙatar cire granite, muna jika cinya. Masu fasahar mu suna tsaftacewa bayan kansu, suna da kyau, sauri da kuma daidai. Wannan yana da mahimmanci saboda farashin sabis ɗin farantin granite ya haɗa da lokacin raguwar ku da samarwa da kuka rasa. Gyaran da ya dace yana da mahimmancin mahimmanci, kuma bai kamata ku taɓa zaɓar ɗan kwangila akan farashi ko dacewa ba. Wasu aikin daidaitawa suna buƙatar ƙwararrun mutane masu horarwa. Muna da haka.

Rahoton Ƙarshe na Ƙarshe

Ga kowane gyare-gyaren farantin karfe da daidaitawa, muna ba da cikakkun rahotannin ƙwararru. Rahotanninmu sun ƙunshi adadi mai yawa na mahimman bayanai da mahimmanci. Fed Spec. yana buƙatar mafi yawan bayanan da muka bayar. Ban da waɗanda ke ƙunshe a cikin wasu ƙa'idodi masu inganci kamar ISO/IEC-17025, mafi ƙarancin Fed. Takaddun bayanai don rahotanni sune:

- Girma a cikin Ft. (X' x x)

- Launi

- Salo (Yana nufin babu ledoji masu ɗaure ko ɗakuna biyu ko huɗu)

- Ƙimar Modulus na Ƙarfafawa

- Ma'anar Haƙurin Jirgin sama (An ƙaddara ta Matsayi/ Girman)

- Maimaita Haƙurin karatu (An ƙayyade ta tsawon diagonal a inci)

- Ma'anar Jirgin kamar yadda aka samo

- Nufin Jirgin sama kamar hagu

- Maimaita karatu kamar yadda aka samu

- Maimaita karatu kamar hagu

- Delta T (Bambancin yanayin zafi tsakanin saman sama da ƙasa)

Idan ma'aikacin yana buƙatar aiwatar da aikin lapping ko gyarawa a saman farantin, to, takardar shaidar calibration tana tare da madaidaicin yanki ko yanki na isometric don tabbatar da ingantaccen gyara.

Kalma Game da ISO/IEC-17025 Amincewa da Lab ɗin da ke da su

Kawai saboda lab yana da izini a cikin daidaitawar faranti ba lallai ba ne yana nufin sun san abin da suke yi da ƙasa da yin shi daidai! Hakanan baya nufin cewa lab na iya gyarawa. Ƙungiyoyin da ke ba da izini ba su bambanta tsakanin tabbatarwa ko daidaitawa (gyara).AKuma na san daya, watakila2hukumomin da suka amince da suLkunnen dokiAribbon a kusa da kare na idan na biya musu isasshen kuɗi! Gaskiya ce mai ban tausayi. Na ga labs sun sami izini ta hanyar yin ɗayan gwaje-gwaje guda uku da ake buƙata. Bugu da ƙari, na ga labs sun sami izini tare da rashin tabbas na gaskiya kuma ana samun izini ba tare da wata hujja ko nuna yadda suke ƙididdige ƙimar ba. Duk abin takaici ne.

Taƙaice

Ba za ku iya raina aikin madaidaicin faranti na granite ba. Bayanin lebur wanda faranti na granite ke bayarwa shine tushen da kuke yin duk sauran ma'auni akansa.

Kuna iya amfani da mafi zamani, mafi inganci kuma mafi yawan kayan aunawa. Koyaya, ingantattun ma'auni suna da wuya a tantance idan farfajiyar tunani ba ta faɗi ba. Wani lokaci, na sami wani abokin ciniki mai yiwuwa ya ce mani "da kyau dutse ne kawai!" Amsa na, "Ok, kun yi daidai, kuma ba shakka ba za ku iya ba da hujjar sa masana sun shigo don kula da farantinku ba."

Farashin bai taɓa zama dalili mai kyau don zaɓar ƴan kwangilar farantin ƙasa ba. Masu saye, masu ba da lissafi da yawan masu tayar da hankali na ingantattun injiniyoyi ba koyaushe suke fahimtar cewa sake tabbatar da faranti ba kamar sake tabbatar da micrometer, caliper ko DMM ba.

Wasu kayan aikin suna buƙatar ƙwarewa, ba ƙaramin farashi ba. Bayan faɗin haka, ƙimar mu tana da ma'ana sosai. Musamman don samun amincewa cewa muna yin aikin daidai. Muna da kyau fiye da ISO-17025 da ƙayyadaddun ƙayyadaddun tarayya a cikin ƙarin ƙimar.

Farantin saman sune tushen ma'aunai masu yawa, kuma kulawa da kyaun farantinka yana da mahimmanci don tabbatar da daidaiton aunawa.

Granite shine mafi mashahuri kayan da ake amfani da su don faranti na saman saboda kyawawan halayensa na zahiri, kamar taurin saman da ƙarancin hankali ga canjin yanayin zafi. Koyaya, tare da ci gaba da amfani da faranti na saman suna fuskantar lalacewa.

Latsawa da maimaitawa duka biyun mahimman al'amura ne don tantance ko farantin yana samar da madaidaicin saman don samun ma'auni daidai ko a'a. An bayyana haƙuri ga bangarorin biyu a ƙarƙashin Ƙayyadaddun Tarayya GGG-P-463C, DIN, GB, JJS ... Flatness shine ma'auni na nisa tsakanin matsayi mafi girma (jirgin rufin) da mafi ƙasƙanci (jirgin tushe) a kan farantin. Maimaituwa yana ƙayyade idan za'a iya maimaita ma'aunin da aka ɗauka daga yanki ɗaya a duk faɗin farantin cikin haƙurin da aka bayyana. Wannan yana tabbatar da cewa babu kololuwa ko kwari a cikin farantin. Idan ba a cikin ƙa'idodin da aka bayyana ba, to ana iya buƙatar sakewa don dawo da ma'auni cikin ƙayyadaddun bayanai.

Daidaita farantin karfe na yau da kullun yana da mahimmanci don tabbatar da kwanciyar hankali da maimaitawa akan lokaci. Madaidaicin rukunin ma'auni a Cross shine ISO 17025 wanda aka ba da izini don daidaita farantin faranti da maimaitawa. Muna amfani da Mahr Surface Plate Certification System wanda ke nuna:

- Mody and Profile Analysis,

- Shirye-shiryen isometric ko Lambobi,

- Matsakaicin Gudu da yawa, da

- Ƙididdiga ta atomatik bisa ga Ka'idodin Masana'antu.

Samfurin Taimakon Kwamfuta na Mahr yana ƙayyadaddun kowane karkatacciyar kusurwa ko madaidaiciyar matakin daga cikakken matakin, kuma ya dace da ingantaccen bayanin faranti.

Tazara tsakanin gyare-gyare zai bambanta dangane da yawan amfani, yanayin muhalli inda farantin yake, da takamaiman buƙatun ingancin kamfanin ku. Tsayawa farantinka da kyau na iya ba da damar dogon tazara tsakanin kowane gyare-gyare, yana taimaka maka ka guje wa ƙarin farashin sake dawowa, kuma mafi mahimmanci yana tabbatar da ma'aunin da ka samu akan farantin daidai gwargwadon yiwuwa. Ko da yake faranti na saman suna da ƙarfi, kayan aiki ne na daidai kuma ya kamata a kula da su kamar haka. Ga wasu abubuwan da za ku yi la'akari da su game da kula da farantin ku:

- Tsaftace farantin, kuma idan zai yiwu a rufe shi lokacin da ba a amfani da shi

- Babu wani abu da ya kamata a sanya a kan farantin banda gage ko guntu da za a auna.

- Kada ku yi amfani da wuri ɗaya akan farantin kowane lokaci.

- Idan zai yiwu, juya farantin lokaci-lokaci.

- Mutunta iyakar nauyin farantin ku

Daidaitaccen Tushen Granite na iya Inganta Ayyukan Kayan Aikin Inji

Bukatun suna karuwa akai-akai a aikin injiniyan injiniya gabaɗaya kuma a cikin ginin kayan aikin injin. Samun madaidaicin daidaito da ƙimar aiki ba tare da ƙarin farashi ba ƙalubale ne na yau da kullun don kasancewa gasa. Gadon kayan aikin injin shine muhimmin abu anan. Sabili da haka, ƙarin masana'antun kayan aikin injin suna dogaro da granite. Saboda sigogi na zahiri, yana ba da fa'idodi masu fa'ida waɗanda ba za a iya samun su da karfe ko simintin polymer ba.

Granite wani abin da ake kira dutse mai zurfi mai aman wuta kuma yana da tsari mai yawa kuma mai kama da juna tare da ƙarancin haɓakar haɓakawa, ƙarancin ƙarfin zafi da babban jijjiga.

A ƙasa zaku gano dalilin da yasa ra'ayi na gama gari cewa granite ya fi dacewa kawai azaman tushen injin don injunan aunawa mai tsayi ya daɗe kuma me yasa wannan kayan halitta azaman tushen kayan aikin injin shine mafi fa'ida madadin ƙarfe ko simintin ƙarfe har ma da kayan aikin injin madaidaici.

Za mu iya kera kayan aikin granite don motsi mai ƙarfi, kayan aikin granite don injunan linzamin kwamfuta, abubuwan granite don ndt, abubuwan granite don xray, abubuwan granite don cmm, abubuwan granite don cnc, madaidaicin granite don Laser, abubuwan granite don sararin samaniya, abubuwan granite don matakan madaidaicin ...

Ƙimar Ƙarar Ƙarfafa Ba tare da Ƙarin Kuɗi ba

Ƙara yawan amfani da granite a cikin injiniyan injiniya ba shi da yawa saboda yawan karuwar farashin karfe. Maimakon haka, saboda ƙarin ƙimar kayan aikin injin da aka samu tare da gadon injin da aka yi da granite yana yiwuwa a ɗan ƙaramin farashi ko babu kari. An tabbatar da wannan ta hanyar kwatancen farashi na sanannun masana'antun kayan aikin injin a Jamus da Turai.

Babban riba a cikin kwanciyar hankali na ma'aunin zafi da sanyio, jijjiga jijjiga da daidaito na dogon lokaci da granite ya yi ba za a iya samu tare da simintin ƙarfe ko gadon ƙarfe ba, ko kuma a farashi mai tsada kawai. Misali, kurakurai na thermal na iya yin lissafin kusan kashi 75% na jimlar kuskuren injin, tare da biyan diyya sau da yawa ana ƙoƙarin yin ta software - tare da matsakaicin nasara. Saboda ƙarancin ƙarancin wutar lantarki, granite shine mafi kyawun tushe don daidaito na dogon lokaci.

Tare da juriya na 1 μm, granite sauƙi ya dace da buƙatun flatness bisa ga DIN 876 don matakin daidaito 00. Tare da darajar 6 akan sikelin taurin 1 zuwa 10, yana da wuyar gaske, kuma tare da takamaiman nauyin 2.8g / cm³ kusan ya kai darajar aluminum. Wannan kuma yana haifar da ƙarin fa'idodi kamar ƙimar abinci mafi girma, haɓakar axis da haɓaka rayuwar kayan aiki don yankan kayan aikin injin. Don haka, canji daga gadon simintin gyare-gyare zuwa gadon injin granite yana motsa kayan aikin injin da ake tambaya a cikin aji mai girma dangane da daidaito da aiki - ba tare da ƙarin farashi ba.

Ingantaccen Sawun Muhalli na Granite

Ya bambanta da kayan kamar karfe ko simintin ƙarfe, ba dole ba ne a samar da dutse na halitta tare da yawan kuzari da amfani da ƙari. Ana buƙatar ƙananan adadin kuzari kaɗan don tsagawa da jiyya na ƙasa. Wannan yana haifar da ingantaccen sawun muhalli, wanda ko a ƙarshen rayuwar injin ya zarce na ƙarfe a matsayin abu. Gadon granite na iya zama tushen sabon injin ko kuma a yi amfani da shi don dalilai daban-daban kamar shredding don gina hanya.

Haka kuma babu ƙarancin albarkatun don granite. Dutse ne mai zurfi da aka samu daga magma a cikin ɓawon ƙasa. Ya 'balaga' na miliyoyin shekaru kuma ana samunsa da yawa a matsayin albarkatun ƙasa a kusan dukkanin nahiyoyi, gami da duk Turai.

Kammalawa: Yawancin fa'idodin da ake iya nunawa na granite idan aka kwatanta da karfe ko simintin ƙarfe suna ba da hujjar ƙara son injiniyoyin injiniyoyi don amfani da wannan abu na halitta a matsayin tushe don ingantattun kayan aikin injin. Cikakken bayani game da kaddarorin granite, waɗanda ke da fa'ida ga kayan aikin injin da injiniyan injiniya, ana iya samun su a cikin wannan ƙarin labarin.

Ma'auni mai maimaitawa shine ma'auni na wurare masu laushi na gida. Ƙayyadaddun ma'aunin maimaitawa yana faɗin cewa ma'aunin da aka ɗauka a ko'ina a saman farantin zai maimaita cikin haƙurin da aka bayyana. Sarrafa shimfidar wuri mai ƙarfi fiye da shimfidar wuri gabaɗaya yana ba da garantin canji a hankali a cikin bayanin martabar shimfidar wuri ta haka rage kurakuran gida.

Yawancin masana'antun, gami da samfuran da aka shigo da su, suna bin ƙayyadaddun ƙayyadaddun tarayya na jurewar rashin kwanciyar hankali gabaɗaya amma da yawa suna watsi da ma'aunin maimaitawa. Yawancin ƙananan ƙima ko faranti na kasafin kuɗi da ake samu a kasuwa a yau ba za su ba da garantin maimaita ma'auni ba. Mai sana'anta wanda ba ya bada garantin maimaita ma'auni baya samar da faranti waɗanda suka dace da buƙatun ASME B89.3.7-2013 ko Ƙididdigar Tarayya GGG-P-463c, ko DIN 876, GB, JJS ...

Dukansu biyu suna da mahimmanci don tabbatar da madaidaicin saman don ingantattun ma'auni. Ƙayyadaddun ƙwanƙwasa kawai bai isa ba don tabbatar da daidaiton aunawa. Ɗauki a matsayin misali, 36 X 48 Inspection Grade A saman farantin, wanda ya dace da ƙayyadaddun ƙayyadaddun .000300 KAWAI". A zahiri, zai iya zama mafi girma idan gage ɗin yana hutawa a kan gangaren karkata.

Kurakurai na .000600"-.000800" na iya yiwuwa, ya danganta da tsananin gangare, da tsayin hannun gage ɗin da ake amfani da shi. Idan wannan farantin yana da ƙayyadaddun ma'aunin maimaitawa na .000050"FIR to kuskuren auna zai zama ƙasa da .000050" ba tare da la'akari da inda aka ɗauki ma'aunin akan farantin ba. Wata matsalar kuma, wacce galibi ke tasowa lokacin da wani ma’aikacin da ba a horar da shi ya yi ƙoƙari ya sake tayar da faranti a wurin ba, ita ce amfani da Maimaita Measurements kaɗai don tabbatar da faranti.

Ba a ƙirƙira kayan aikin da ake amfani da su don tabbatar da maimaitawa ba don duba faɗuwa gabaɗaya. Lokacin da aka saita su zuwa sifili akan saman mai lanƙwasa daidai, za su ci gaba da karanta sifili, shin wannan farfajiyar ta yi daidai ko daidai gwargwado ko kuma convex 1/2"! Suna kawai tabbatar da daidaiton farfajiyar, ba madaidaicin ba. Sai kawai farantin da ya dace da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ma'aunin maimaitawa da gaske ya dace da buƙatun ASME B89.3.7-2013G3G3.

Ask us about or flatness specification and repeat measurement promise by calling +86 19969991659 or emailing INFO@ZHHIMG.COM

Ee, amma ana iya ba da garantin su kawai don ƙayyadaddun yanayin zafin jiki na tsaye. Tasirin haɓakar zafi a kan farantin zai iya haifar da sauyi a cikin daidaito cikin sauƙi fiye da haƙuri idan akwai canji a cikin gradient. A wasu lokuta, idan haƙurin ya yi ƙarfi sosai, zafin da aka sha daga hasken sama zai iya haifar da isasshen canjin gradient a cikin sa'o'i da yawa.

Granite yana da ƙayyadaddun ƙayyadaddun haɓakar haɓakar zafi na kusan .0000035 inci kowace inch a kowace 1°F. Misali: A 36" x 48" x 8" farantin yana da daidaiton .000075" (1/2 na Grade AA) a ma'aunin 0°F, sama da ƙasa suna da zafi iri ɗaya. Idan saman farantin ya yi dumi har zuwa inda ya fi 1 ° F zafi fiye da kasa, daidaito zai canza zuwa .000275" convex ! Saboda haka, yin odar faranti tare da juriya fiye da Laboratory Grade AA ya kamata a yi la'akari kawai idan akwai isasshen yanayin kula da yanayi.

Ya kamata a goyi bayan farantin saman a maki 3, wanda ya dace ya kasance 20% na tsawon daga ƙarshen farantin. Ya kamata a sami goyon baya biyu 20% na nisa daga cikin dogayen ɓangarorin, kuma sauran goyon bayan ya kamata a tsakiya. Maki 3 ne kawai za su iya tsayawa da ƙarfi akan komai sai madaidaicin saman.

Ya kamata a tallafa wa farantin a waɗannan wuraren yayin samarwa, kuma ya kamata a tallafa shi kawai a waɗannan maki uku yayin amfani. Ƙoƙarin tallafawa farantin a sama da maki uku zai sa farantin ya sami goyon bayansa daga haɗuwa daban-daban na maki uku, wanda ba zai kasance daidai da maki 3 da aka tallafa masa a lokacin samarwa ba. Wannan zai gabatar da kurakurai yayin da farantin ke juyawa don dacewa da sabon tsarin tallafi. Duk ginshiƙan ƙarfe na zhhimg suna da katako mai goyan baya da aka tsara don yin layi tare da madaidaitan wuraren tallafi.

Idan farantin yana da goyan bayan da kyau, daidaitaccen daidaitawa yana zama dole kawai idan aikace-aikacenku ya kira shi. Matsayi ba lallai ba ne don kiyaye daidaiton farantin da aka goyan baya da kyau.

Me yasa Zabi Granite donInjin TushenkumaAbubuwan da ake buƙata na tsarin awo?

Amsar ita ce 'e' ga kusan kowane aikace-aikacen. Fa'idodin granite sun haɗa da: Babu tsatsa ko lalata, kusan kariya daga warping, babu hump lokacin da aka niƙa shi, tsawon rayuwa, aiki mai laushi, mafi girman daidaito, kusan mara ƙarfi, ƙarancin haɓakar haɓakar thermal, da ƙarancin kulawa.

Granite wani nau'i ne na dutsen da aka haƙa don tsananin ƙarfinsa, yawa, dorewa, da juriya ga lalata. Amma granite kuma yana da amfani sosai - ba kawai don murabba'ai da rectangles ba! A gaskiya ma, Starrett Tru-Stone yana aiki da ƙarfin gwiwa tare da kayan aikin granite da aka ƙera su a cikin siffofi, kusurwoyi, da lanƙwasa na kowane bambance-bambance akai-akai-tare da kyakkyawan sakamako.

Ta hanyar aikin mu na fasaha, yanke saman na iya zama na musamman lebur. Waɗannan halayen suna sa granite ya zama abin da ya dace don ƙirƙirar ƙira-ƙira da ƙira na ƙirar injin da abubuwan haɗin metrology. Granite shine:

inji

daidai lebur idan an yanke kuma an gama

tsatsa resistant

m

mai dorewa

Abubuwan Granite kuma suna da sauƙin tsaftacewa. Lokacin ƙirƙirar ƙirar al'ada, tabbatar da zaɓar granite don fa'idodinsa mafi girma.

Ma'auni/ KYAUTA KYAUTA

granite da ZhongHui ke amfani da shi don daidaitattun samfuran farantin mu yana da babban abun ciki na quartz, wanda ke ba da juriya ga lalacewa da lalacewa. Launukanmu na Baƙar fata da Crystal Pink suna da ƙarancin shayar ruwa, suna rage yuwuwar tsatsawar madaidaicin gages ɗinku yayin saitawa akan faranti. Launuka na granite da ZhongHui ke bayarwa suna haifar da ƙarancin haske, wanda ke nufin ƙarancin ido ga mutane masu amfani da faranti. Mun zaɓi nau'ikan granite ɗin mu yayin da muke la'akari da haɓaka yanayin zafi a ƙoƙarin kiyaye wannan yanayin kaɗan.

ABUBUWAN DA AKE YIWA

Lokacin da aikace-aikacenku ya yi kira ga faranti mai siffofi na al'ada, abubuwan da aka saka, ramummuka ko wasu machining, za ku so ku zaɓi abu kamar Black Diabase. Wannan abu na halitta yana ba da ƙoshin ƙarfi, kyakkyawan damping na girgiza, da ingantattun injina.

Ee, idan ba a sa su da kyau ba. Saitin masana'anta da kayan aikin mu suna ba da damar ingantattun yanayi don daidaitaccen farantin karfe da sake yin aiki idan ya cancanta. Gabaɗaya, idan farantin yana cikin .001 "na haƙurin da ake buƙata, ana iya sake farfado da shi a kan wurin. Idan farantin yana sawa har ya wuce .001" ba tare da haƙuri ba, ko kuma idan ya yi mummunan rauni ko kuma an yi shi da kyau, to za a buƙaci a aika zuwa masana'anta don niƙa kafin a sake dawowa.

Yakamata a yi taka tsantsan wajen zabar gyare-gyaren kan layi da gyare-gyaren gyare-gyare. Muna roƙon ku da ku yi taka tsantsan wajen zaɓar sabis ɗin daidaitawar ku. Nemi izini da kuma tabbatar da kayan aikin da ma'aikacin zai yi amfani da shi yana da Cibiyar Bincike ta Ƙasa da za a iya ganowa. Yana ɗaukar shekaru masu yawa don koyan yadda ake yin daidaitaccen granite daidai.

ZhongHui yana ba da saurin juyowa akan ƙirar da aka yi a masana'antar mu. Aika faranti don daidaitawa idan zai yiwu. Ingancin ku da darajar ku sun dogara ne akan daidaiton kayan aikin ku gami da faranti!

Baƙin saman faranti ɗinmu suna da girma sosai kuma suna da ƙarfi har sau uku. Saboda haka, farantin da aka yi da baƙar fata ba ya buƙatar zama mai kauri kamar farantin granite mai girman guda don samun daidai ko mafi girma juriya ga karkatarwa. Rage kauri yana nufin ƙarancin nauyi da ƙananan farashin jigilar kaya.

Hattara da wasu waɗanda ke amfani da ƙananan granite baƙar fata a cikin kauri ɗaya. Kamar yadda aka bayyana a sama, kaddarorin granite, kamar itace ko ƙarfe, sun bambanta da kayan abu da launi, kuma ba daidaitaccen ma'auni bane na taurin, tauri, ko juriya. A gaskiya ma, yawancin nau'in granite baki da diabase suna da taushi sosai kuma basu dace da aikace-aikacen farantin karfe ba.

A'a. Kayan aiki na musamman da horon da ake buƙata don sake yin waɗannan abubuwa yana buƙatar mayar da su zuwa masana'anta don daidaitawa da sake yin aiki.

Ee. Ceramic da granite suna da halaye iri ɗaya, kuma hanyoyin da ake amfani da su don daidaitawa da granite za a iya amfani da su tare da abubuwan yumbu kuma. Ceramics sun fi wuya a cinya fiye da granite wanda ke haifar da farashi mai girma.

Ee, muddin an rufe abubuwan da aka saka a ƙasan saman. Idan abubuwan da aka sanya na karfe suna juye da, ko sama da saman jirgin, dole ne a fuskanci tabo kafin farantin karfe. Idan an buƙata, za mu iya ba da wannan sabis ɗin.

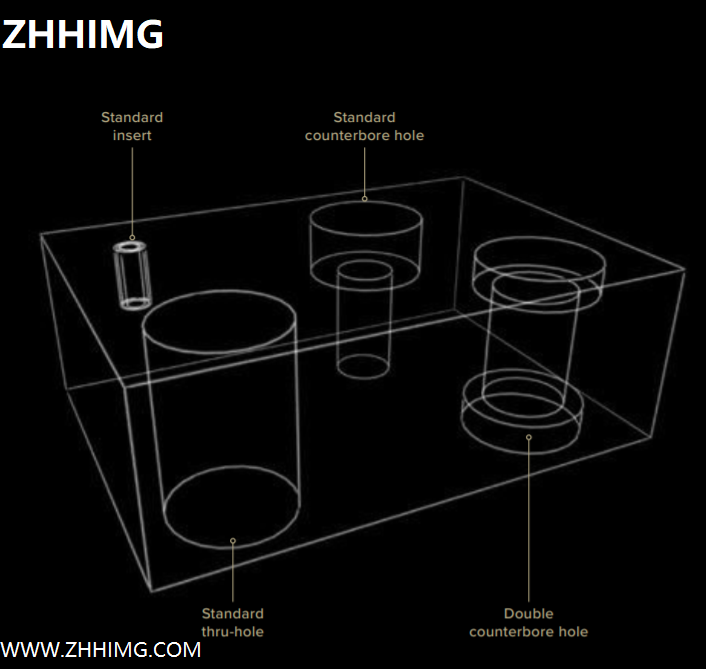

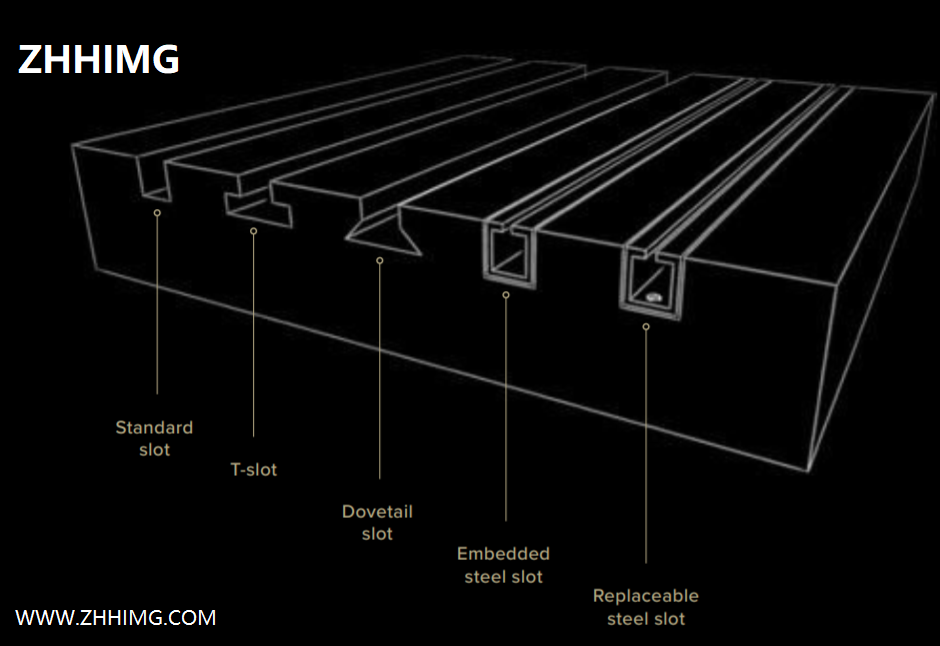

Ee. Abubuwan da aka saka karafa tare da zaren da ake so (Turanci ko metric) ana iya haɗa su a cikin farantin a wuraren da ake so. ZhongHui yana amfani da injunan CNC don samar da mafi girman wuraren da aka saka a cikin +/- 0.005 "Don ƙananan abubuwan da ake sakawa, haƙurin wurinmu don abubuwan da aka saka shine ±.060". Sauran zaɓuɓɓukan sun haɗa da T-Bars na ƙarfe da ramukan dovetail da aka ƙera kai tsaye cikin granite.

Abubuwan da aka saka waɗanda aka haɗa su da kyau ta amfani da ƙarfin epoxy mai ƙarfi da kyakkyawan aiki za su iya jure babban ƙarfin torsional da ƙarfi. A cikin gwaji na baya-bayan nan, ta amfani da 3/8 "-16 threaded inserts, wani dakin gwaje-gwaje mai zaman kansa ya auna ƙarfin da ake buƙata don cire abun da aka haɗa da epoxy daga faranti. An gwada faranti goma. Daga cikin waɗannan goma, a cikin lokuta tara, granite ya karye farko. Matsakaicin nauyin a ma'anar gazawar shine 10,020 lbs. na launin toka 2, 31 da kuma lbs na baki. An ja shi kyauta daga farantin, nauyin da ke kan gazawar ya kasance 12,990 lbs.

Ee, amma a masana'antar mu kawai. A shukarmu, za mu iya mayar da kusan kowane faranti zuwa yanayin 'kamar-sabon', yawanci akan ƙasa da rabin farashin maye gurbinsa. Za a iya daidaita gefuna da suka lalace ta hanyar kwalliya, ƙwanƙwasa mai zurfi, nick, da ramuka za a iya fitar da su, kuma ana iya maye gurbin goyan bayan da aka haɗe. Bugu da ƙari, za mu iya canza farantin ku don ƙara haɓakar sa ta ƙara daɗaɗɗen ƙarfe mai ƙarfi ko zaren abin sakawa da yankan ramummuka ko matse lebe, gwargwadon ƙayyadaddun ku.

Me yasa Zabi Granite?

Granite wani nau'i ne na dutsen da aka kafa a duniya miliyoyin shekaru da suka wuce. Abubuwan da ke tattare da dutsen da ke da banƙyama ya ƙunshi ma'adanai da yawa kamar ma'adini mai wuyar gaske da juriya. Bugu da ƙari ga tauri da sawa juriya granite yana da kusan rabin adadin haɓaka kamar simintin ƙarfe. Da yake nauyinsa ya kai kusan kashi ɗaya bisa uku na baƙin ƙarfe na simintin gyare-gyare, granite yana da sauƙin yin motsi.

Don sansanonin injina da kayan aikin awo, granite baki shine launi da aka fi amfani dashi. Black granite yana da kashi mafi girma na ma'adini fiye da sauran launuka kuma shine, saboda haka, mafi wuyar sawa.

Granite yana da tasiri mai tsada, kuma yanke saman na iya zama na musamman lebur. Ba wai kawai za a iya latsa shi da hannu ba don cimma matsananciyar daidaito, amma ana iya sake yin kwandishan ba tare da motsa faranti ko tebur ba daga wurin. Gabaɗaya aikin latsawa hannu ne kuma gabaɗaya tsadar sa ya yi ƙasa da sake daidaita madaidaicin simintin ƙarfe.

Waɗannan halayen suna sa granite ya zama ingantaccen abu don ƙirƙirar ƙira-ƙira da ƙira na musamman na injin da abubuwan haɗin kai kamar sufarantin granite.

ZhongHui yana samar da samfuran granite da aka ƙirƙira don tallafawa takamaiman buƙatun auna. Waɗannan abubuwan da ake magana sun bambanta dagamadaidaiciya gefuna tomurabba'ai uku. Saboda nau'in nau'in granite, daaka gyaraza a iya samar da kowane girman da ake bukata; suna da wuyar sawa kuma suna daɗe.

Amfanin farantin saman saman Granite

Mahimmancin aunawa akan ko'ina sama ne wanda ɗan ƙasar Burtaniya Henry Maudsley ya kafa shi a cikin 1800s. A matsayin mai ƙididdige kayan aikin injin, ya ƙaddara cewa daidaitaccen samar da sassa yana buƙatar ingantaccen saman don ma'auni masu dogaro.

Juyin juya halin masana'antu ya haifar da buƙatar auna filaye, don haka kamfanin injiniya Crown Windley ya ƙirƙiri matsayin masana'antu. Crown ya fara saita ma'auni don faranti na sama a cikin 1904 ta amfani da ƙarfe. Yayin da buƙatu da tsadar ƙarfe ke ƙaruwa, an bincika madadin kayan aikin aunawa.

A Amurka, mahaliccin abin tunawa Wallace Herman ya tabbatar da cewa granite baƙar fata shine kyakkyawan farantin farantin karfe maimakon ƙarfe. Kamar yadda granite ba Magnetic ba ne kuma baya tsatsa, nan da nan ya zama saman aunawa da aka fi so.

Farantin granite yana da mahimmancin saka hannun jari don dakunan gwaje-gwaje da wuraren gwaji. Za a iya saka farantin dutse mai girman 600 x 600 mm akan madaidaicin tallafi. Tsayin yana ba da tsayin aiki na 34" (0.86m) tare da maki biyar daidaitacce don daidaitawa.

Don ingantaccen sakamako mai daidaituwa da daidaito, farantin granite yana da mahimmanci. Da yake saman jirgin sama mai santsi ne kuma tsayayye, yana ba da damar sarrafa kayan aiki a hankali.

Babban abũbuwan amfãni daga granite surface faranti ne:

• Mara tunani

• Juriya ga sinadarai da lalata

• Low coefficient na fadada idan aka kwatanta da cart baƙin ƙarfe don haka rage rinjayar da zazzabi canji

• Tafarki na dabi'a da wuyar sawa

• Jirgin saman saman ba ya shafar idan an taso

• Ba zai yi tsatsa ba

• Mara maganadisu

• Sauƙi don tsaftacewa da kulawa

• Ana iya yin gyare-gyare da haɓakawa a wurin

• Dace da hakowa ga threaded goyon bayan abun da ake sakawa

• Babban jijjiga damping

Don shaguna da yawa, dakunan dubawa da dakunan gwaje-gwaje, an dogara da madaidaicin faranti na granite a matsayin tushen ingantaccen auna. Domin kowane ma'aunin linzamin kwamfuta ya dogara da ingantaccen wurin tunani wanda aka ɗauko ma'auni na ƙarshe, faranti na saman suna samar da mafi kyawun jirgin sama don duba aiki da shimfidar wuri kafin mashin ɗin. Hakanan madaidaitan tushe ne don yin ma'aunin tsayi da filaye mai gagewa. Bugu da ari, babban mataki na flatness, kwanciyar hankali, gabaɗaya inganci da aikin aiki ya sa su zama zaɓi mai kyau don hawa nagartattun injiniyoyi, lantarki da tsarin gaging na gani. Ga kowane ɗayan waɗannan matakan aunawa, yana da mahimmanci a kiyaye faranti na saman ƙasa.

Maimaita Ma'auni da Lalacewa

Dukansu flatness da maimaita ma'auni suna da mahimmanci don tabbatar da daidaitaccen wuri. Ana iya la'akari da kwanciyar hankali kamar yadda duk maki a saman yana ƙunshe a cikin jiragen sama guda biyu masu kama da juna, jirgin ƙasa da kuma rufin rufin. Ma'auni na nisa tsakanin jiragen shine gaba ɗaya lebur na saman. Wannan ma'aunin kwanciyar hankali yawanci yana ɗaukar juriya kuma yana iya haɗawa da ƙima.

An ayyana haƙƙoƙin daɗaɗɗa don ma'auni guda uku a cikin ƙayyadaddun tarayya kamar yadda aka ƙaddara ta wannan dabara:

Matsayin dakin gwaje-gwaje AA = (40 + diagonal² / 25) x 0.000001 inch (bangare)

Matsayin dubawa A = Matsayin dakin gwaje-gwaje AA x 2

Dakin Kayan aiki Grade B = Matsayin dakin gwaje-gwaje AA x 4

Baya ga flatness, dole ne a tabbatar da maimaitawa. Ma'auni mai maimaitawa shine ma'auni na wurare masu laushi na gida. Ma'auni ne da aka ɗauka a ko'ina a saman faranti wanda zai maimaita cikin haƙurin da aka bayyana. Sarrafa shimfidar wuri na gida zuwa mafi tsananin juriya fiye da shimfidar wuri gabaɗaya yana ba da garantin canji a hankali a cikin bayanin martabar shimfidar ƙasa, ta haka rage kurakuran gida.

Don tabbatar da farantin saman ya dace da duka biyun da kuma maimaita ƙayyadaddun ma'auni, masana'antun faranti na granite yakamata suyi amfani da Ƙayyadaddun Tarayya GGG-P-463c azaman tushen ƙayyadaddun su. Wannan daidaitaccen adireshi yana maimaita daidaiton aunawa, kaddarorin kayan kayan granites na saman farantin, ƙarewar saman, wurin goyan baya, taurin kai, hanyoyin dubawa da shigarwa na abubuwan da aka saka.

Kafin farantin saman ya sawa fiye da ƙayyadaddun ƙayyadaddun ƙayyadaddun labulen gabaɗaya, zai nuna sawa ko sawa. Binciken wata-wata don maimaita kurakuran auna ta amfani da maimaita karatun gage zai gano tabo. Maimaita karatun gage babban kayan aiki ne wanda ke gano kuskuren gida kuma ana iya nunawa akan babban ƙararrakin lantarki.

Duban Sahihancin Farantin

Ta bin ƴan sauƙi jagororin, zuba jari a cikin farantin granite ya kamata ya wuce shekaru masu yawa. Dangane da amfani da farantin, yanayin shago da daidaiton da ake buƙata, yawan duba daidaiton farantin ya bambanta. Babban ƙa'idar babban yatsan hannu shine sabon faranti don karɓar cikakken sakewa a cikin shekara ɗaya na siyan. Idan ana amfani da farantin akai-akai, yana da kyau a rage wannan tazara zuwa watanni shida.

Kafin farantin saman ya sawa fiye da ƙayyadaddun ƙayyadaddun ƙayyadaddun labulen gabaɗaya, zai nuna sawa ko sawa. Binciken wata-wata don maimaita kurakuran auna ta amfani da maimaita karatun gage zai gano tabo. Maimaita karatun gage babban kayan aiki ne wanda ke gano kuskuren gida kuma ana iya nunawa akan babban ƙararrakin lantarki.

Ingantacciyar shirin dubawa yakamata ya haɗa da cak na yau da kullun tare da autocollimator, yana ba da ainihin daidaitawa na gabaɗaya flatness wanda za'a iya ganowa zuwa Cibiyar Matsayi da Fasaha ta ƙasa (NIST). Cikakken daidaitawa ta masana'anta ko kamfani mai zaman kansa ya zama dole lokaci zuwa lokaci.

Bambance-bambance Tsakanin Calibrations

A wasu lokuta, ana samun bambance-bambance tsakanin matakan daidaita faranti. Wasu lokuta dalilai kamar canjin yanayi da ke haifar da lalacewa, rashin amfani da kayan aikin dubawa ko amfani da kayan aikin da ba a daidaita su ba na iya yin lissafin waɗannan bambance-bambancen. Abubuwa biyu da suka fi kowa yawa, duk da haka, sune zafin jiki da tallafi.

Ɗaya daga cikin mahimman masu canji shine zafin jiki. Misali, ana iya wanke saman da bayani mai zafi ko sanyi kafin a daidaita kuma ba a ba da isasshen lokaci don daidaitawa ba. Sauran abubuwan da ke haifar da canjin zafin jiki sun haɗa da zazzagewar sanyi ko iska mai zafi, hasken rana kai tsaye, hasken sama ko wasu hanyoyin samun zafi a saman farantin.

Hakanan ana iya samun bambance-bambance a cikin madaidaicin zafin jiki tsakanin hunturu da bazara. A wasu lokuta, ba a ba da izinin farantin isasshen lokaci don daidaitawa bayan jigilar kaya. Yana da kyau a yi rikodin zafin jiki a tsaye a lokacin da ake yin gyare-gyare.

Wani dalili na gama-gari don bambance-bambancen daidaitawa shine farantin da aka goyan baya da kyau. Ya kamata a goyan bayan farantin saman a maki uku, wanda ya dace da 20% na tsayin ciki daga ƙarshen farantin. Ya kamata a sami goyon baya biyu 20% na nisa daga cikin dogayen ɓangarorin, kuma sauran goyon bayan ya kamata a tsakiya.

Maki uku ne kawai za su iya tsayawa da ƙarfi akan komai sai madaidaicin saman. Ƙoƙarin tallafawa farantin a sama da maki uku zai sa farantin ya sami goyon bayansa daga haɗuwa daban-daban na maki uku, wanda ba zai kasance daidai da maki uku da aka tallafa masa a lokacin samarwa ba. Wannan zai gabatar da kurakurai yayin da farantin ke juyawa don dacewa da sabon tsarin tallafi. Yi la'akari da yin amfani da madaidaicin karfe tare da katako mai goyan baya da aka tsara don yin layi tare da madaidaitan wuraren tallafi. Tsaye don wannan dalili gabaɗaya ana samun su daga masana'anta farantin.

Idan farantin yana da goyon baya da kyau, daidaitaccen daidaitawa ya zama dole kawai idan aikace-aikacen ya ƙayyade shi. Matsayi ba lallai ba ne don kiyaye daidaiton farantin da aka goyan baya da kyau.

Yana da mahimmanci a kiyaye farantin karfe mai tsabta. Kurar ƙurar ƙura ta iska yawanci ita ce mafi girman tushen lalacewa da tsagewa a kan faranti, saboda tana ƙoƙarin shigar da kayan aiki da wuraren tuntuɓar gages. Rufe faranti don kare su daga ƙura da lalacewa. Za a iya tsawaita rayuwar sawa ta hanyar rufe farantin lokacin da ba a amfani da ita.

Tsawaita Rayuwar Plate

Bin wasu ƴan jagorori zai rage lalacewa akan farantin granite kuma a ƙarshe, tsawaita rayuwarsa.

Na farko, yana da mahimmanci a kiyaye farantin karfe. Kurar ƙurar ƙura ta iska yawanci ita ce mafi girman tushen lalacewa da tsagewa a kan faranti, saboda tana ƙoƙarin shigar da kayan aiki da wuraren tuntuɓar gages.

Hakanan yana da mahimmanci a rufe faranti don kare shi daga ƙura da lalacewa. Za a iya tsawaita rayuwar sawa ta hanyar rufe farantin lokacin da ba a amfani da ita.

Juya farantin lokaci-lokaci don kada yanki ɗaya ya sami amfani da yawa. Har ila yau, ana ba da shawarar maye gurbin takalmin tuntuɓar ƙarfe a kan gaging tare da sandunan carbide.

Ka guji saita abinci ko abin sha a faranti. Yawancin abubuwan sha masu laushi sun ƙunshi ko dai carbonic ko phosphoric acid, wanda zai iya narkar da ma'adanai masu laushi kuma ya bar ƙananan ramuka a saman.

Inda za a Komawa

Lokacin da farantin granite yana buƙatar sake buɗewa, la'akari da ko za a yi wannan sabis ɗin a wurin ko a wurin daidaitawa. Zai fi kyau koyaushe a sake dawo da farantin a masana'anta ko wurin da aka keɓe. Idan, duk da haka, farantin ba a sawa sosai ba, gabaɗaya tsakanin 0.001 inch na haƙurin da ake buƙata, ana iya sake farfado da shi akan rukunin yanar gizon. Idan farantin yana sawa har ya wuce inci 0.001 don haƙuri, ko kuma idan an yi masa mummunan rami ko kuma an yi shi da kyau, to sai a aika shi zuwa masana'anta don niƙa kafin a sake dawowa.

Wurin daidaitawa yana da kayan aiki da saitin masana'anta suna samar da ingantattun yanayi don daidaita faranti mai kyau da sake yin aiki idan ya cancanta.

Yakamata a yi taka tsantsan wajen zabar gyare-gyaren kan layi da gyare-gyaren gyare-gyare. Nemi izini kuma tabbatar da kayan aikin da ma'aikacin zai yi amfani da shi yana da ma'auni na NIST. Kwarewa kuma muhimmin abu ne, saboda ana ɗaukar shekaru masu yawa don koyon yadda ake daidaita madaidaicin granite.

Ma'auni masu mahimmanci suna farawa da madaidaicin farantin granite a matsayin tushe. Ta hanyar tabbatar da abin dogara ta hanyar amfani da farantin da aka daidaita daidai, masana'antun suna da ɗaya daga cikin mahimman kayan aikin don ma'auni masu dogara da mafi kyawun sassa.

Jerin abubuwan dubawa don Bambance-bambancen Calibration

- An wanke saman tare da bayani mai zafi ko sanyi kafin a daidaita shi kuma ba a ba da izinin isasshen lokaci don daidaitawa ba.

- Ana goyan bayan farantin da bai dace ba.

- Canjin yanayin zafi.

- Zane-zane.

- Hasken rana kai tsaye ko wani zafi mai haskakawa a saman farantin. Tabbatar cewa hasken sama baya dumama saman.

- Bambance-bambance a cikin yanayin zafin jiki na tsaye tsakanin hunturu da bazara. Idan za ta yiwu, san yanayin zafi a tsaye a lokacin da ake yin gyare-gyare.

- Ba a ba da izinin farantin isashen lokaci don daidaitawa bayan jigilar kaya.

- Yin amfani da kayan bincike mara kyau ko amfani da kayan aikin da ba daidai ba.

- Canjin yanayin da ke faruwa sakamakon lalacewa.

Tips na Fasaha

Domin kowane ma'aunin linzamin kwamfuta ya dogara da ingantaccen wurin tunani wanda aka ɗauko ma'auni na ƙarshe, faranti na saman suna samar da mafi kyawun jirgin sama don duba aiki da shimfidar wuri kafin mashin ɗin.

Sarrafa shimfidar wuri na gida zuwa mafi tsananin juriya fiye da shimfidar wuri gabaɗaya yana ba da garantin canji a hankali a cikin bayanin martabar shimfidar ƙasa, ta haka rage kurakuran gida.