A cikin dakunan gwaje-gwaje masu natsuwa, ɗakunan tsaftacewa na semiconductor, da kuma ɗakunan nazarin sararin samaniya, ana ci gaba da juyin juya hali na shiru. Ba wai software ko firikwensin kaɗai ke jagoranta ba—amma ta hanyar kayan da suka samar da tushen aunawa da kansu. A sahun gaba na wannan canjin akwai kayan aikin auna yumbu na zamani, waɗanda suka haɗa da na'urar auna iska mai ƙarfi ta yumbu da kuma na'urar silicon-carbide mai tsauri (Si-SiC) mai kama da murabba'i. Waɗannan ba kayan aiki kawai ba ne; suna ba da damar sabon zamani inda kwanciyar hankali, maimaitawa, da rashin tsaka tsaki na zafi ba za a iya yin shawarwari ba.

Tsawon sama da rabin ƙarni, dutse mai launin baƙi ya mamaye tsarin daidaiton ma'aunin ƙasa. Ƙarfinsa na halitta, ƙarancin faɗaɗa zafi, da kuma kyakkyawan siffa mai kyau sun sa ya zama kayan da ake amfani da su don faranti na saman, murabba'ai, da gefuna madaidaiciya. Duk da haka yayin da masana'antu ke matsa lamba ga jurewar ƙananan micron har ma da nanometer - musamman a cikin lithography na semiconductor, na'urorin hangen nesa na sararin samaniya, da kuma ƙididdigar kwantum - iyakokin granite sun bayyana ƙarara. Yana da nauyi, yana da sauƙin kamuwa da ƙananan chipping yayin da ake maimaita hulɗa, kuma, duk da suna, har yanzu yana nuna ɗan gajeren lokaci a ƙarƙashin kaya ko canjin muhalli.

Shiga cikin yumbun da aka ƙera: ba tukwane masu rauni na tunanin yau da kullun ba, amma kayan aiki masu yawa, masu kama da juna, masu aiki mai girma waɗanda aka ƙera a ƙarƙashin zafi mai tsanani da matsin lamba. Daga cikin waɗannan, azuzuwan biyu sun shahara don aikace-aikacen metrology: alumina mai tsarki (Al₂O₃) da silicon carbide mai haɗin amsawa (Si-SiC). Duk da cewa duka biyun suna ba da ci gaba mai ban mamaki akan kayan gargajiya, suna aiki daban-daban - kuma tare, suna wakiltar ƙarshen abin da zai yiwu a cikin metrology mai girma.

Misali, ɗauki ma'aunin iska mai madaidaiciyar siffa ta yumbu. An ƙera shi don amfani da matakan ɗaukar iska ko na'urorin auna haske, wannan kayan aikin yana buƙatar madaidaicin siffa, ƙaramin nauyi, da kuma rashin saurin ɗumama zafi.shugabanni na yumbu—an yi musu injinan zuwa lanƙwasa da madaidaiciya a cikin ±0.5 µm sama da 500 mm kuma an goge su zuwa ƙazanta a saman ƙasa da Ra 0.02 µm—suna isar da hakan daidai. Ƙananan yawansu (~3.6 g/cm³) yana rage rashin kuzari a cikin tsarin aunawa mai ƙarfi, yayin da yanayinsu mara maganadisu, mara jagoranci yana kawar da tsangwama a cikin yanayin lantarki ko maganadisu masu mahimmanci. A cikin kayan aikin duba wafer ko saitunan daidaitawa na laser, inda har ma da ƙaramin baka zai iya karkatar da sakamako, mai mulkin iska mai madaidaiciya na yumbu yana ba da ma'anar tsayayye, mara motsi wanda ya kasance gaskiya a duk lokacin canjin zafin jiki da zagayowar aiki.

Amma idan ana buƙatar tauri da kuma ƙarfin jurewa na zafi—kamar a cikin madubin hangen nesa na sararin samaniya ko kuma a cikin tsarin aunawa na ramin laser mai ƙarfi—injiniyoyi suna komawa ga sassan silicon-carbide masu daidaito (Si-SiC) masu layi ɗaya da murabba'i. Si-SiC yana ɗaya daga cikin kayan da aka fi sani, tare da tsarin Young wanda ya wuce 400 GPa—fiye da sau uku na ƙarfe—da kuma ƙarfin jurewa na zafi wanda ya yi gogayya da aluminum. Mafi mahimmanci, ana iya ƙera coefficient na faɗaɗa zafi (CTE) don ya dace da na gilashin gani ko wafers na silicon, wanda ke ba da damar faɗaɗa bambancin kusan sifili a cikin haɗuwa masu haɗaka. Murabba'in Si-SiC da aka yi amfani da shi azaman babban ma'auni a cikin kayan aikin lithography na EUV ba zai riƙe siffarsa kawai ba—zai yi tsayayya da karkacewa daga dumama ko girgiza na gida.

Abin da ke sa waɗannan nasarorin su yiwu ba wai kawai kayan ba ne, har ma da ƙwarewar ƙera kayan aikin auna yumbu. Misali, injinan Si-SiC masu daidaito suna buƙatar ƙafafun niƙa lu'u-lu'u, dandamalin CNC mai ƙananan micron, da kuma hanyoyin lapping matakai da yawa da ake gudanarwa a cikin yanayin zafi. Ko da ƙaramin matsin lamba da ya rage daga sintering mara kyau na iya haifar da warpage bayan injin. Shi ya sa wasu ƙwararrun masana'antun duniya suka haɗa haɗakar kayan aiki, ƙirƙirar daidaito, da kuma metrology na ƙarshe a ƙarƙashin rufin gida ɗaya—ikon da ke raba masu samar da daidaiton metrology na gaskiya daga masu samar da yumbu gabaɗaya.

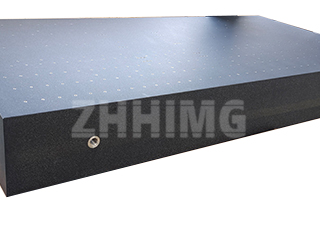

A ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG), wannan haɗin kai tsaye yana da mahimmanci ga aikinmu. Kayan aikin auna yumbunmu - gami da samfuran ruler mai madaidaiciyar iska na yumbu waɗanda aka ba da takardar shaida ga DIN 874 Grade AA da kayan tarihi masu daidaito da murabba'i waɗanda aka gano bisa ga ƙa'idodin PTB da NIST - ana samar da su a cikin ɗakunan tsabta na ISO Class 7 ta amfani da ƙa'idodin sintering na mallaka da kammalawa. Kowane sashi yana yin cikakken tantancewa tsakanin juna, tabbatar da CMM na jurewar geometric (fadi, daidaituwa, perpendicularity), da gwajin ingancin saman kafin jigilar kaya. Sakamakon shine kayan tarihi na matakin tunani wanda ba wai kawai ya cika takamaiman bayanai ba - ya fi su akai-akai a cikin rukuni-rukuni.

Bukatar irin wannan aiki yana ƙaruwa. A cikin masana'antar semiconductor, tsarin EUV da tsarin lithography mai girma-NA suna buƙatar tsarin daidaitawa wanda ya daidaita zuwa cikin goma na nanometers akan nisan mita - ba zai yiwu ba tare da haɗin gwiwar thermal-injiniya na Si-SiC. A cikin sararin samaniya, benci na gani na tauraron dan adam da aka yi da nassoshi na yumbu suna tabbatar da kwanciyar hankali a kan kewaya duk da tsananin zagayowar zafi. Ko da a cikin fannoni masu tasowa kamar gano raƙuman nauyi ko haɓaka agogon atomic, inda kwanciyar hankali na matakin picometer ke da mahimmanci, kayan tarihi na yumbu da Si-SiC suna zama ba makawa.

A mahimmin mahimmanci, waɗannan kayan aikin suna magance dorewa da jimlar kuɗin mallakar. Duk da cewa saka hannun jari na farko a cikin silicon-carbide mai daidaito mai kyau na iya wuce na daidai gwargwado na granite, tsawon lokacin aikinsa na iya zama sau 5-10 a cikin yanayin da ake amfani da shi sosai. Ba ya buƙatar mai, yana tsayayya da duk abubuwan narkewa da plasma na gama gari, kuma ba ya buƙatar sake daidaitawa saboda sha danshi - ba kamar ƙarfen siminti ko ma wasu granites ba. Ga manajoji masu inganci waɗanda ke aiki a ƙarƙashin ƙa'idodin AS9100, ISO 13485, ko SEMI, wannan aminci yana fassara kai tsaye zuwa raguwar lokacin aiki, ƙarancin binciken bincike, da ƙarin kwarin gwiwa ga abokan ciniki.

Bugu da ƙari, bai kamata a yi watsi da kyawun waɗannan kayan aikin ba. Si-SiC mai gogewa yana haskakawa tare da walƙiyar ƙarfe amma yana da nauyi ƙasa da ƙarfe. Mai sarrafa iska mai madaidaiciyar yumbu yana jin ƙarfi amma yana ɗagawa cikin sauƙi - ya dace don tabbatar da hannu a cikin wurare masu tauri. Waɗannan halaye masu mayar da hankali kan ɗan adam suna da mahimmanci a cikin dakunan gwaje-gwaje na zahiri inda ergonomics da sauƙin amfani ke shafar aikin yau da kullun.

To, shin kayan aikin auna yumbu suna sake fasalta daidaito mai girma sosai? Amsar tana cikin bayanai - da kuma jerin shugabannin duniya masu tasowa waɗanda yanzu suka ayyana su a matsayin mizani. Daga cibiyoyin nazarin ƙasa da ke tabbatar da ka'idojin tsayin ƙarni na gaba zuwa masu samar da kayayyaki na Tier 1 waɗanda ke tabbatar da sassan EV drivetrain, canjin a bayyane yake: lokacin da dole ne a rage rashin tabbas, injiniyoyi suna amincewa da yumbun da aka ƙera.

Kuma yayin da masana'antu ke ci gaba da tafiya mai tsayi zuwa ga sarrafa sikelin atomic, gaskiya ɗaya ta zama abin da ba za a iya musantawa ba: makomar aunawa ba za a sassaka ta da dutse ko ƙarfe ba. Za a niƙa ta da ruwa, a niƙa ta, sannan a goge ta da yumbu—da kuma silicon carbide.

ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG) wani kamfani ne da aka sani a duniya wajen kirkire-kirkire a fannin hanyoyin aunawa na yumbu da silicon-carbide. Ya ƙware a fannin kayan aikin auna yumbu, mai daidaita iska ta yumbu, da kuma kayan aikin silicon-carbide masu inganci (Si-SiC) masu layi daya da murabba'i, ZHHIMG yana samar da kayan tarihi masu inganci, masu inganci a fannin dakin gwaje-gwaje don aikace-aikacen binciken semiconductor, jiragen sama, tsaro, da kimiyya. Tare da takaddun shaida na ISO 9001, ISO 14001, da CE, manyan kamfanonin fasaha a duk duniya sun amince da kayayyakinmu. Bincika fayil ɗin metrology ɗinmu mai zurfi awww.zhhimg.com.

Lokacin Saƙo: Disamba-05-2025