A matsayin "maƙasudin ginshiƙi" na auna daidaito da ƙera kayayyaki, dandamalin granite na daidaitawa, tare da daidaiton su na musamman da daidaiton daidaitawa, sun shiga manyan fannoni kamar ƙera daidai, binciken sararin samaniya, motoci, da kuma nazarin metrology. Babban darajar su ta ta'allaka ne da samar da yanayin dubawa da haɗa abubuwa iri-iri, wanda ya dace da buƙatun dukkan sarkar samar da kayayyaki, daga injinan gargajiya zuwa tsarin metrology mai wayo.

Muhimman Yanayi na Aikace-aikace da Dacewar Masana'antu

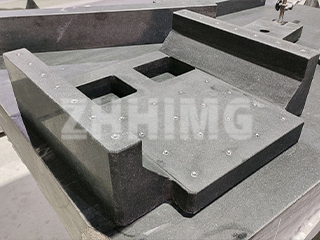

A fannin kera kayayyaki daidai, dandamalin granite sune "masu tsaron ƙofa" na kula da inganci: daidaita daidaiton geometric na kayan aikin injin CNC, duba matakin micron na lanƙwasa na mold, da kuma tabbatar da girma na sassan da aka buga da 3D duk sun dogara ne akan farfajiyar da aka tabbatar da dorewar su. Misali, a cikin kera mold, dandamalin, tare da ma'aunin tsayi, zai iya auna zurfin rami daidai, yana tabbatar da daidaiton sassan da aka ƙera tare da zane-zanen ƙira.

Matuƙar ƙoƙarin da masana'antar sararin samaniya ke yi na tabbatar da daidaito ya sanya dandamalin granite su zama manyan aikace-aikace. Duba saman ruwan turbine, auna jurewar tubalan injin, har ma da haɗa da sanya sassan tauraron ɗan adam duk suna buƙatar dandamali a matsayin faranti na daidaita sararin samaniya don samar da ma'aunin saman matakin submicron. Bayanai daga kamfanin kera jiragen sama sun nuna cewa amfani da dandamalin granite mai maki 00 ya rage kurakuran aunawa a cikin sassan injin da kashi 15%, wanda ke inganta amincin injin gaba ɗaya.

A fannin samar da kayayyaki da yawa a masana'antar kera motoci, dandamali suna aiki a matsayin "masu kariya masu inganci": auna ma'aunin gear a cikin watsawa da kuma tabbatar da daidaiton kauri na birki. Tare da kayan aiki kamar masu kwatantawa na gani, suna ba da damar ingantaccen dubawa na rukunin sassa. Wani babban kamfanin kera motoci ya bayyana cewa amfani da dandamalin granite tare da ramukan T a layin samarwa ya ƙara ingancin matse sassan da kashi 30% da kuma inganta daidaiton bayanan gwaji da kashi 22%.

A dakunan gwaje-gwajen metrology, dandamalin granite sune masu daidaita daidaito. A matsayin tushen granite na CMM don injunan aunawa masu daidaitawa (CMMs), suna samar da matakin tunani don auna tsayi, suna tabbatar da daidaiton daidaitawa na tubalan ma'auni, micrometers, da sauran kayan aikin aunawa. Manyan dakunan gwaje-gwajen metrology na duniya, kamar NIST (Cibiyar Ma'auni da Fasaha ta Ƙasa), suna kafa tsarin kimanta tsayin su akan dandamalin granite masu inganci. Rarraba Kasuwa ta Duniya da Zaɓuɓɓukan Yanki

Bukatar kasuwa a yankuna daban-daban tana nuna bambance-bambance masu yawa, wanda ke nuna haɗin kai mai zurfi tsakanin ƙa'idodin masana'antu da yanayin aikace-aikacen:

Yanayin Kasuwar Duniya

Arewacin Amurka (32%): Masana'antun sararin samaniya da semiconductor ne ke jagoranta, yana mai da hankali kan daidaito da bin ka'idojin takaddun shaida, kamar bin diddigin NIST da kuma amincewa da dakin gwaje-gwaje na ISO 17025. Aikace-aikacen da aka saba amfani da su sun haɗa da auna bayanan ruwan wukake na injinan jiragen sama.

Turai (38%): Tana da rinjaye a fannin kayan aiki na daidai da kuma masana'antar kera motoci, tana fifita ƙa'idodin DIN da kayan da ba su da illa ga muhalli, kamar granite mai ƙarancin fitar da hayaki wanda ya yi daidai da DIN 876. Babban kamfanin kera motoci na Jamus Bosch Group ya ƙayyade wannan dandamali don daidaita na'urorin auna firikwensin tuƙi mai cin gashin kansa.

Asiya-Pacific (CAGR 7.5%): China da Indiya su ne manyan injunan ci gaba, waɗanda buƙatu mai yawa a masana'antar kayan lantarki (kamar marufi da gwaji) da sabbin motocin makamashi ke haifarwa. Masana'antun gida suna amfani da fa'idodin farashi don kama kasuwannin ƙasa da matsakaici yayin da suke hanzarta takardar shaidar ISO 17025 don karya shinge a cikin kasuwar mai girma.

Daga daidaitawar aiki zuwa keɓancewa na yanki, dandamalin granite mai daidaitawa yana jagorantar tuƙin ƙafa biyu na "ƙirar da ta dogara da yanayi + takardar shaida mai daidaito," wanda ke zama babban cibiya da ke haɗa kera daidai da sarrafa inganci. Ko dai yana aiki a matsayin tushen granite na CMM don tallafawa kayan aikin aunawa masu inganci ko kuma a matsayin farantin daidaita sararin samaniya don tabbatar da amincin jiragen sama, "ƙimarsa" a cikin raƙuman Masana'antu 4.0 zai ci gaba da fice.

Lokacin Saƙo: Satumba-11-2025