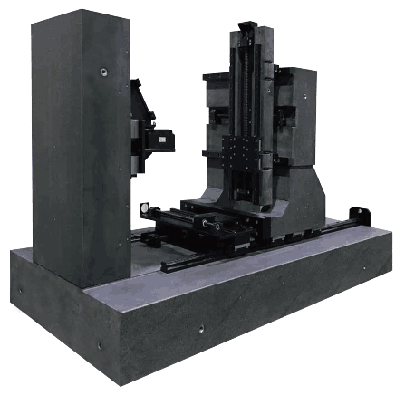

A masana'antar kera semiconductor da nuni, kayan aikin duba array suna taka muhimmiyar rawa wajen tabbatar da ingancin samfura. Ingancin waɗannan injunan za a iya ƙara su sosai ta hanyar zaɓar kayan da aka yi amfani da su a cikin injina, kuma granite ya zama abin da ke canza wannan fanni.

Kwanciyar hankali mara misaltuwa don Aiki Mai Dorewa

Duba jeri yana buƙatar daidaiton maƙasudi, domin ko da ƙaramin karkacewa zai iya haifar da sakamako na ƙarya ko kuma kurakurai da aka rasa. Tushen injinan granite, tare da yawansu na kusan 3100 kg/m³, suna ba da kwanciyar hankali na musamman. A lokacin aikin dubawa, kayan aikin na iya fuskantar girgiza daga injina ko abubuwan muhalli na kusa. Tsarin tsayuwar granite yana tsayayya da waɗannan rikice-rikice na waje yadda ya kamata, yana kiyaye na'urori masu auna sigina da abubuwan gani daidai. Wannan kwanciyar hankali yana tabbatar da cewa kayan aikin na iya ci gaba da duba jeri daidai, yana rage buƙatar sake dubawa da inganta yawan fitarwa gaba ɗaya. Misali, a cikin masana'antar nunin faifai, amfani da tushen injinan granite a cikin kayan aikin duba jeri ya haifar da ƙaruwar kashi 20% a cikin ƙarfin dubawa na yau da kullun.

Babban Damfarar Girgiza don Sauri

Girgizawa na iya kawo cikas ga saurin duba tsari. Lokacin da kayan aikin dubawa suka yi rawar jiki, sau da yawa dole ne a rage saurin duba don kiyaye daidaito, wanda ke rage jinkirin dukkan aikin. Girgizar halitta ta granite - halayen damshi babban fa'ida ne a nan. Tsarinsa na musamman na ciki, wanda ya ƙunshi ƙwayoyin ma'adinai masu haɗaka, yana sha da kuma wargaza kuzarin girgiza yadda ya kamata. Tare da tushen injin granite, kayan aikin duba tsari na iya aiki a cikin saurin dubawa mafi girma ba tare da la'akari da daidaito ba. A cikin masana'antar kera semiconductor, bayan maye gurbin tushen ƙarfe na asali da na granite, saurin dubawa na jerin da'ira da aka haɗa ya ƙaru da kashi 30%, wanda ke ba da damar zagayowar samarwa cikin sauri.

Juriyar Zafi don Tsawaita Lokacin Aiki

Sauye-sauyen zafin jiki sun zama ruwan dare a cikin yanayin masana'antu, kuma suna iya shafar aikin kayan aikin duba tsari. Wasu kayan na iya faɗaɗa ko ƙunsar canje-canjen zafin jiki, wanda ke haifar da rashin daidaiton kayan aiki da kuma duba ba daidai ba. Granite yana da ƙarancin ma'aunin faɗaɗa zafi, wanda ke nufin yana kiyaye siffarsa da girmansa ko da a ƙarƙashin yanayin zafi daban-daban. Wannan kwanciyar hankali na zafi yana bawa kayan aikin duba tsari damar aiki akai-akai ba tare da buƙatar gyare-gyare akai-akai da zafin jiki ke haifarwa ba. Sakamakon haka, kayan aikin na iya aiki na tsawon lokaci, yana ƙara yawan amfani da shi da kuma inganta inganci. A cikin layin samar da girma mai yawa, amfani da tushen injinan granite ya rage lokacin dakatar da kayan aiki saboda matsalolin zafi da kashi 40%.

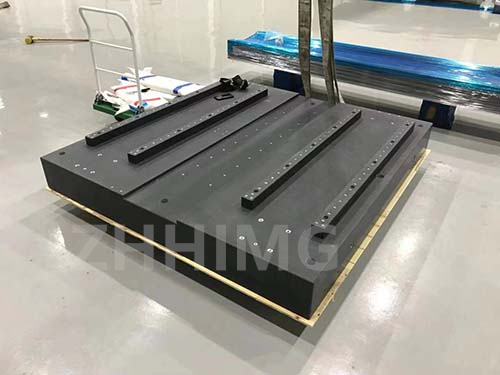

Dorewa Mai Dorewa Don Farashi Mai Inganci - Ayyuka Masu Inganci

Ana amfani da kayan aikin duba tsari akai-akai a wuraren masana'antu, kuma tushen injin yana buƙatar jure wa wahalar aiki na yau da kullun. Granite yana da ƙarfi sosai, tare da kyakkyawan juriya - juriya da rashin kuzarin sinadarai. Yana iya jure wa matsin lamba na injiniya, gogayya, da yuwuwar fallasa sinadarai a cikin yanayin masana'antu. Wannan dorewa mai ɗorewa yana rage yawan maye gurbin tushe da kulawa, yana rage farashin aiki gabaɗaya. Bugu da ƙari, ingantaccen tushen injin granite yana tabbatar da aiki mai ɗorewa na kayan aikin duba tsari, yana ƙara ba da gudummawa ga haɓaka inganci.

A ƙarshe, tushen injinan granite na iya inganta ingancin kayan aikin duba array sosai. Kwanciyar hankalinsu, ƙarfin girgizarsu, juriyar zafi, da juriyarsu suna aiki tare don ba da damar dubawa cikin sauri, daidai, da inganci. Ga masana'antun da ke neman inganta hanyoyin samar da su da kuma ƙara yawan aikin duba array ɗinsu, saka hannun jari a cikin tushen injinan granite masu inganci, kamar waɗanda ZHHIMG® ya bayar, shawara ce mai kyau wacce za ta iya samar da fa'idodi masu yawa.

Lokacin Saƙo: Yuni-10-2025