A duniyar masana'antu masu inganci sosai—inda juriya ke raguwa ƙasa da microns 5 kuma ƙarewar saman yana kusantar ingancin gani—kayan aikin da muke dogara da su dole ne su ci gaba fiye da al'ada. Shekaru da yawa, ƙarfe da granite sun mamaye benci na metrology. Amma yayin da masana'antu kamar kayan aikin semiconductor, na'urorin gani na sararin samaniya, da ƙananan na'urori na likitanci ke matsawa zuwa wurare inda ko da ɗumamar zafi ko lalacewar ƙananan na'urori ke haifar da kuskuren da ba za a iya yarda da shi ba, wani sabon nau'in kayan aikin tunani yana tasowa: waɗanda ba a ƙera su da ƙarfe ko dutse ba, amma daga yumbu na fasaha na zamani.

A ZHHIMG, mun wuce kawai bayar daMai mulkin Yumbu Madaidaiciyako samfuran Ceramic Square Ruler. Muna sake fasalta abin da gefen madaidaiciya zai iya zama—ta hanyar haɗa kayan yumbu masu ƙarfi da ƙira ta zamani, gami da ruler ɗinmu mai ban mamaki na iska mai iyo na Ceramic, mafita wanda ke kawar da hulɗa ta injiniya gaba ɗaya yayin da yake samar da maimaitawa matakin nanometer.

Me yasa ake yin yumbu? Amsar ta fara ne daga matakin kwayoyin halitta. Ba kamar ƙarfe ba—wanda ke faɗaɗa sosai da zafin jiki—ko granite—wanda, duk da kwanciyar hankalinsa, ya kasance mai ramuka da bambance-bambance—tukwane masu injiniya kamar zirconia-toughened alumina (ZTA) da silicon nitride suna ba da kusan sifili porosity, tauri na musamman (1400–1800 HV), da kuma ma'aunin faɗaɗa zafi ƙasa da 3–4 µm/m·°C. Wannan yana nufin Ceramic Straight Edge daga ZHHIMG yana kula da yanayinsa a duk lokacin da zafin jiki ya canza wanda zai iya karkatar da kayan aikin gargajiya da microns da yawa.

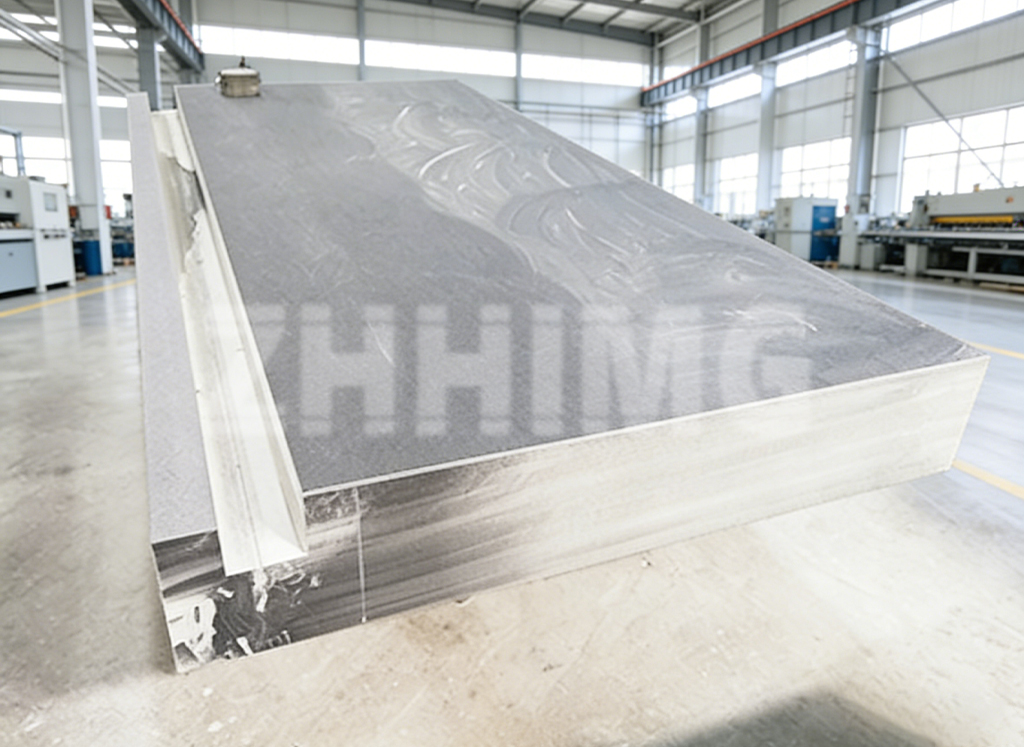

Amma kayan kawai bai isa ba. Abin da ya bambanta masu sarrafa yumbu namu shine daidaiton ƙera su. Ta amfani da niƙa lu'u-lu'u, goge ƙasa da rami, da kuma tabbatar da laser interferometric a cikin ɗakunan tsaftacewa na ISO Class 5, muna samun juriyar madaidaiciya fiye da 0.8 µm sama da 500 mm - an tabbatar ba kawai a lokacin isarwa ba, amma an rubuta su a cikin cikakkun rahotannin daidaitawa waɗanda aka gano bisa ga ƙa'idodin NIST da PTB.Mai mulkin murabba'in yumbuYana yin gwajin perpendicularity ta hanyar amfani da na'urar lantarki ta atomatik, yana tabbatar da cewa kusurwoyi suna riƙe a cikin daƙiƙa 1 (≈0.5 µm karkacewa a 100 mm).

Waɗannan ba ƙa'idodi ba ne na ka'ida. Gaskiya ne na aiki ga abokan ciniki waɗanda ba za su iya sake yin sulhu ba. Wani babban mai samar da kayan aikin lithography na EUV yanzu yana amfani da Ceramic Straight Ruler ɗinmu kawai don daidaita firam ɗin tallafin madubi. "Masu rukunonin ƙarfe sun lalace yayin zagayowar fallasa mai tsawo," in ji babban masanin kimiyyar metro ɗinsu. "Granite ya ɗauki barbashi. Sigar yumbu? Ya kasance mai karko tsawon watanni 18—ba a buƙatar sake daidaita ta."

Duk da haka ko da cikakkiyar siffar za a iya lalata ta hanyar hulɗa. Ja mai mulki a saman wani abu, kuma kuna fuskantar haɗarin ƙananan gogewa, tsangwama a cikin fim ɗin mai, ko lalacewar roba - musamman akan ƙarfe masu laushi ko na'urorin gani masu gogewa. A nan ne sabuwar fasahar ZHHIMG ta yi fice tare da mai mulki mai iyo na iska na Ceramic na Custom.

Wannan ba wai kawai gefen yumbu ne madaidaiciya wanda aka haƙa ramuka a ciki ba. Tsarin iska ne mai cikakken injiniya, wanda aka tsara ta amfani da tsarin sarrafa ruwa don isar da iska mai kama da laminar a duk tsawon mai mulki. Idan aka matsa shi da iska mai tsabta da bushewa (ko nitrogen a cikin yanayi mai laushi), mai mulki yana shawagi a cikin microns 5-10 sama da aikin - yana kawar da taɓawa ta jiki yayin da yake kiyaye daidaiton daidaito. Sakamakon? Gaskiya ma'aunin rashin taɓawa don tabbatar da lanƙwasa, madaidaiciya, ko tsayin matakai, tare da maimaitawa ƙasa zuwa ±0.2 µm.

Wani dakin gwaje-gwajen kwamfuta na kwantum a Switzerland yanzu yana amfani da na'urar auna iska ta musamman ta Ceramic mai girman mm 600 don duba na'urorin auna guntu masu sarrafa guntu. "Duk wani hulɗa - ko da tare da stylus mai laushi - yana gabatar da damuwa wanda ke canza aikin qubit," in ji injiniyan aikinsu. "Na'urar auna iska ta ceramic mai shawagi tana ba mu ma'aunin da muke buƙata ba tare da taɓa ɓangaren ba. Ya zama mai mahimmanci ga aikin."

Abin da ya sa hakan zai yiwu shi ne haɗin gwiwar ZHHIMG na musamman na kimiyyar kayan aiki, injinan daidaitacce, da ƙwarewar nazarin yanayin ƙasa. Duk da yake masu samar da kayayyaki da yawa suna ɗaukar yumbu a matsayin kayan gini, muna inganta su azaman kayan aiki na aunawa. Tsarin Ceramic Square Ruler ɗinmu ya haɗa da gefuna masu kauri don hana guntuwar, bayan da aka gama da matte don rage haske a ƙarƙashin hasken dubawa, da kuma alamun aminci na zaɓi don tsarin gani na atomatik. Don aikace-aikacen ɗaki mai tsabta, ana goge saman zuwa Ra < 0.02 µm don rage mannewar barbashi.

Kuma saboda kowace aikace-aikace ta bambanta, ba mu yarda da girman ɗaya ba. Kuna buƙatar Gefen Tsaye Mai Tsayi na Ceramic tare da tashoshin injin tsabtacewa da aka haɗa don ɗaukar siririn wafers yayin dubawa? Mun gina shi. Kuna buƙatarmai mulki mai murabba'itare da ramukan da suka ratsa sun dace da shawarar binciken CMM ɗinku? Kun gama. Kuna son na'urar auna iska ta musamman ta yumbu tare da na'urori masu auna matsin lamba da kuma ra'ayoyin matakin dijital? Wannan ya riga ya shiga gwajin beta tare da abokin ciniki na sararin samaniya na Tier-1.

An samu karɓuwa a masana'antu. A cikin Binciken Tsarin Nazarin Tsarin Duniya na 2025 na Duniya, an ambaci ZHHIMG a matsayin kamfani ɗaya tilo da ke ba da cikakken iyali na kayan aikin auna yumbu masu inganci - gami da bambance-bambancen iyo - tare da cikakken ingancin lissafi da kuma bin diddigin dijital. Amma mafi mahimmanci, ɗaukar nauyin yana hanzarta: sama da kashi 60% na umarnin sarrafa yumbu yanzu sun fito ne daga masana'antu waɗanda a da suka ɗauki irin waɗannan kayan aikin a matsayin "masu wuce gona da iri" - har sai sun auna bambancin.

Kamfanin samar da na'urorin likitanci da ke samar da dashen jijiyoyi daga ƙarfe zuwa Ceramic Square Ruler ɗinmu kuma sun ga yawan amfani da na'urorinsu na farko ya tashi da kashi 22%. "Tsohon murabba'in ya bar ƙananan ramuka a kan gidajen titanium," in ji manajan QA ɗinsu. "Ba mu ma san hakan ba sai da muka canza. Yanzu, kowane ɓangare ya wuce gwaje-gwajen gani da girma a ƙoƙarin farko."

Don haka yayin da kake kimanta haɓakawar ilimin kimiyyar lissafi na gaba, tambayi kanka: Shin ainihin abin da nake da shi a yanzu yana ƙara rashin tabbas - ko kuma kawar da shi?

Idan tsarin aikinku yana aiki a gefen ganowa, amsar na iya kasancewa a cikin yumbu - ba a matsayin sabon abu ba, amma a matsayin wata bukata. A ZHHIMG, ba wai kawai muna ƙera kayan aikin Ceramic Straight Ruler, Ceramic Square Ruler, ko Ceramic Straight Edge ba ne. Muna ƙera kwarin gwiwa ga kowace micron.

Lokacin Saƙo: Disamba-31-2025