Granite an san shi sosai a matsayin abu mafi dacewa don ma'aunin daidaito saboda kwanciyar hankali, tauri, da juriya ga bambancin zafin jiki. Duk da haka, ba duk granite iri ɗaya bane. Asalin ma'adinan dutse daban-daban - kamar Shandong, Fujian, ko ma daga ƙasashen waje - na iya samar da granite tare da halaye na zahiri daban-daban waɗanda ke tasiri ga dacewarsa don aikace-aikacen daidai.

1. Tsarin Kayan Aiki da Yawansa

Misali, dutse daga Shandong, galibi yana da tsari mai kyau na lu'ulu'u mai yawan yawa da kuma taurin kai mai kyau, wanda ke ba da juriya ga lalacewa da kwanciyar hankali. A gefe guda kuma, dutse na Fujian yana da ɗan haske a launi kuma yana iya samun ma'adanai daban-daban, wanda zai iya shafar aikin rage girgiza da kuma halayen injin.

2. Kwanciyar Hankali da Tsarin Nauyi Mai Ragewa

Faɗaɗa zafi muhimmin abu ne wajen kiyaye daidaiton ma'auni. Granite mai inganci tare da ƙarancin yawan faɗaɗa zafi yana rage canje-canjen girma da canjin yanayin zafi ke haifarwa. Wannan yana sa wasu granites baƙi - kamar waɗanda aka shigo da su daga Shandong ko kuma granite baƙi na Indiya - musamman an fi son su don kayan aiki masu matuƙar daidaito.

3. Kammalawar Sama da Injin Aiki

Tsarin granite da daidaiton hatsi yana ƙayyade yadda za a iya goge shi da hannu ko a lanƙwasa shi yayin samarwa. Tsarin hatsi iri ɗaya yana tabbatar da ingantaccen lanƙwasa da santsi, waɗanda suke da mahimmanci don cimma daidaiton matakin micron.

4. Zaɓar Da Ya Dace da Dutse don Tsarin Daidaitawa

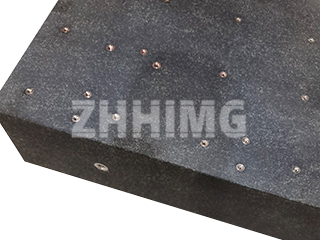

Lokacin zabar kayan granite, masana'antun kamar ZHHIMG suna tantance yawan abu, tauri, da kuma yanayin shaƙar girgiza a hankali. Manufar ita ce a daidaita nau'in granite ɗin da takamaiman yanayin amfani - ko don injunan aunawa masu daidaitawa (CMMs), duba na'urorin gani, ko tsarin haɗa daidai.

A ƙarshe, yayin da dutse na Shandong da Fujian za su iya samar da dandamali masu inganci na aunawa, aikin ƙarshe ya dogara ne akan zaɓin kayan da aka yi da kyau, sarrafa daidai, da kuma daidaita su sosai. Dandalin dutse mai kyau - ba tare da la'akari da asalinsa ba - zai iya samar da daidaito da kwanciyar hankali na dogon lokaci a cikin mawuyacin yanayi na masana'antu.

Lokacin Saƙo: Oktoba-11-2025