;

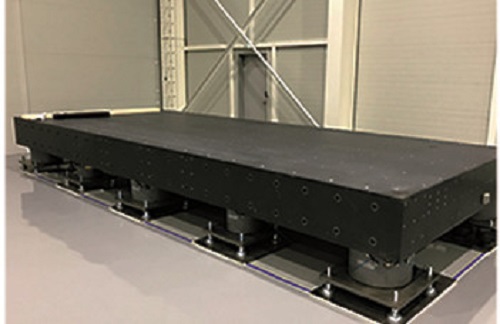

A masana'antar batirin lithium, a matsayin kayan aikin samarwa na asali, kwanciyar hankalin dandamalin motsi na injin rufewa yana taka muhimmiyar rawa a cikin ingancin samar da batirin lithium. A cikin 'yan shekarun nan, kamfanonin kera batirin lithium da yawa sun gano cewa lokacin da suke haɓaka kayan aikinsu, bayan maye gurbin tushen ƙarfe na gargajiya da tushen granite, kwanciyar hankalin dandamalin motsi ya sami babban tsalle. A cewar gwaje-gwaje na gaske, ƙimar inganta kwanciyar hankali ta kai har zuwa 200%. Na gaba, za mu bincika dalilan da ke bayan hakan.

Bambance-bambancen da ke cikin kayan abu suna kafa harsashin kwanciyar hankali

Kwanciyar hankali: Granite yana da fa'idodi masu mahimmanci

A lokacin aikin injin rufe batirin lithium, abubuwa kamar guduwar mota da zafi da gogayya ke haifarwa na iya haifar da sauye-sauye a yanayin zafi a kusa da kayan aiki. Matsakaicin faɗaɗa zafin ƙarfen siminti yana da kusan 12×10⁻⁶/℃, kuma girmansa yana canzawa sosai lokacin da zafin ya bambanta. Misali, lokacin da zafin ya tashi da 10℃, tushen ƙarfen siminti mai tsawon mita 1 na iya tsawaita da 120μm. Matsakaicin faɗaɗa zafin dutse yana da ƙasa sosai, kawai (4-8) ×10⁻⁶/℃. A ƙarƙashin irin wannan yanayi, tsawaita tushen dutse mai tsawon mita 1 shine 40-80μm kawai. Ƙaramin lalacewar zafi yana nufin cewa a cikin yanayin samarwa tare da sauye-sauyen zafin jiki akai-akai, tushen granite zai iya kula da daidaiton farko na dandamalin motsi da kuma tabbatar da kwanciyar hankali na tsarin rufewa.

Tauri da aikin damping: Granite ya fi kyau

Tauri yana ƙayyade ikon abu na juriya ga nakasa, yayin da aikin rage danshi yana da alaƙa da ingancin shan kuzarin girgiza. Duk da cewa ƙarfen siminti yana da takamaiman tauri, yana da tsarin graphite mai laushi a ciki. A ƙarƙashin aikin dogon lokaci na matsin lamba mai canzawa wanda aikin kayan aiki ke haifarwa, yana da saurin tattara damuwa, yana haifar da nakasa da kuma shafar kwanciyar hankali na dandamalin. Sabanin haka, granite yana da tauri a cikin laushi, yana da tsari mai yawa na ciki da kuma kyakkyawan tauri. Tsarin ma'adinai na musamman yana ba shi kyakkyawan aikin rage danshi, yana ba shi damar canza kuzarin girgiza cikin sauri zuwa makamashin zafi don wargajewa. Bincike ya nuna cewa a cikin yanayin girgiza na 100Hz, granite na iya rage girgizar yadda ya kamata cikin daƙiƙa 0.12, yayin da ƙarfen siminti yana buƙatar daƙiƙa 0.9. Lokacin da injin rufe batirin lithium yana aiki a babban gudu, tushen granite na iya rage tsangwama na girgiza akan kan murfin, yana tabbatar da kauri mai daidaito da daidaito.

Tallafin bayanai na adadi don ingantaccen kwanciyar hankali

Gwajin girgiza: Bambancin girman ya bambanta

Cibiyoyin ƙwararru sun gudanar da gwaje-gwajen girgiza a kan dandamalin motsi na injunan rufe batirin lithium waɗanda aka sanye da tushen ƙarfe na siminti da kuma tushen granite bi da bi. Lokacin da injin rufewa ke aiki yadda ya kamata kuma an saita saurin a 100m/min, ana amfani da na'urar firikwensin girgiza mai inganci don auna girman muhimman sassan dandamalin. Sakamakon ya nuna cewa girman dandamalin motsi na tushen ƙarfe na siminti shine 20μm a cikin alkiblar X-axis da 18μm a cikin alkiblar Y-axis. Bayan an maye gurbinsa da tushen granite, girman axis na X ya ragu zuwa 6μm kuma na axis na Y ya ragu zuwa 5μm. Daga bayanan girma, ana iya ganin cewa tushen granite ya rage girman girgiza na dandamalin motsi a manyan hanyoyi biyu da kusan 70%, wanda hakan ya rage tasirin girgiza akan daidaiton rufi da kuma samar da shaida mai ƙarfi don inganta kwanciyar hankali.

Kulawa mai daidaito na dogon lokaci: Ƙara girman kurakurai a hankali

A lokacin gwajin aiki na tsawon awanni 8, an sa ido kan daidaiton matsayi na dandamalin a ainihin lokacin. Lokacin amfani da tushen ƙarfen siminti, kuskuren matsayi na dandamalin yana ƙaruwa a hankali akan lokaci. Bayan awanni 8, kuskuren matsayi na tarin gatari na XY ya kai ±30μm. Kuskuren matsayi na dandamalin motsi tare da tushen granite bayan awanni 8 shine ±10μm kawai. Wannan yana nuna cewa a lokacin aikin samarwa na dogon lokaci, tushen granite zai iya kiyaye daidaiton dandamalin, ya guji karkatar da matsayin shafi da daidaito ya haifar, da kuma tabbatar da fa'idar kwanciyar hankali.

An inganta kwanciyar hankali na ainihin tabbatar da tasirin samarwa

A kan ainihin layin samarwa na wani kamfanin kera batirin lithium, an haɓaka tushen ƙarfe na wasu injunan rufi zuwa tushen granite. Kafin haɓakawa, ƙimar lahani na samfurin ta kai kashi 15%, tare da manyan lahani waɗanda suka haɗa da kauri mara daidaituwa na rufi da karkacewar shafi a gefen takardar lantarki. Bayan haɓakawa, ƙimar lahani na samfuran ta ragu sosai zuwa kashi 5%. Bayan bincike, daidai ne saboda tushen granite yana haɓaka kwanciyar hankali na dandamalin motsi ne tsarin rufewa ya zama mafi daidaito da sarrafawa, yana rage lahani na samfura da dandamali marasa daidaituwa ke haifarwa. Wannan yana nuna cikakken tasirin tushen granite akan ingancin samarwa a cikin injunan rufe batirin lithium.

A ƙarshe, ko daga nazarin ka'idar halayen kayan aiki ne, ainihin bayanan gwajin adadi, ko kuma sakamakon tasirin da aka samu akan layin samarwa, ya nuna a fili cewa inganta kwanciyar hankali na dandamalin motsi na na'urar shafa batirin lithium ta amfani da tushen granite idan aka kwatanta da tushen ƙarfe na siminti zai iya kaiwa 200%. Ga kamfanonin kera batirin lithium waɗanda ke neman inganci da ƙarfin aiki mai girma, babu shakka tushen granite shine babban zaɓi don haɓaka aikin na'urar shafa.

Lokacin Saƙo: Mayu-19-2025