A fannin gyaran wafer na semiconductor, daidaito shine layin rayuwa. Tushen granite mai ban mamaki zai iya haifar da babban ci gaba a cikin aikin kayan aikin gyaran dutse! Waɗanne "masu iko" ne yake ɓoyewa a zahiri? Me yasa aka ce zaɓar tushen granite mai kyau yana nufin kun yi nasara a rabi? A yau, za mu kai ku don bayyana shi dalla-dalla!

I. Ƙarfin Halitta: "Abubuwa Uku Masu Kyau" na Granite

Juriyar girgizar ƙasa ta tabbata kamar Dutsen Tai

Granite yana da yawan da ya kai 2,800-3,100 kg/m³, kuma tsarinsa yana da kauri kamar "kagara ta dutse". A cikin yanayin girgiza mai yawan mita na wafer grooving (rami na kayan aiki sama da sau 100 a minti daya), yana iya shan fiye da kashi 90% na kuzarin girgiza, kamar yadda ake samar wa kayan aiki "fasahar baƙar fata mai ɗaukar girgiza"! Bayanan da aka auna daga wani masana'antar guntu sun nuna cewa bayan amfani da tushen granite, girman girgizar kan mai yanke grooving ya ragu daga 15μm zuwa 3μm, kuma gefunan ƙananan ramuka da aka sassaka suna da santsi kamar madubi.

2. "Tsarin jiki mai jure zafi" Ba tare da tsoron bambance-bambancen zafin jiki ba

Kayan yau da kullun suna "fadadawa da lalacewa" lokacin da aka dumama su kuma suna "ƙuntawa da lalacewa" lokacin da aka sanyaya, amma ƙimar faɗaɗa zafi na granite yana ƙasa da 4-8 × 10⁻⁶/℃, wanda shine 1/5 kawai na ƙarfe! Ko da zafin jiki a cikin wurin aiki yana canzawa sosai da 10℃ cikin awanni 24, lalacewarsa ƙasa da 0.01mm kuma kusan ana iya yin watsi da shi. Wannan yana nufin cewa ba tare da la'akari da canjin dare da rana ko tsawaita aiki da samar da zafi na kayan aiki ba, tushen granite na iya kiyaye matsayin ramin "ba tare da motsi" ba koyaushe.

3. Juriyar lalacewa mara lalacewa

Taurin Mohs na granite ya kai 6 zuwa 7, wanda yayi daidai da na dutse mai siffar quartz, kuma juriyarsa ta ninka ta karfe sau uku! A karkashin dogon lokacin da ake fama da gogayya mai yawan gaske a cikin ramin wafer, saman tushe ba ya lalacewa. Bayan wani kamfanin yin amfani da sansanonin granite na tsawon shekaru biyar, har yanzu ana ci gaba da daidaita shi a cikin ±0.5μm/m bayan an duba shi, kuma daidaiton tsagi ya kasance daidai, wanda ya ceci adadi mai yawa na daidaita kayan aiki da farashin maye gurbinsu.

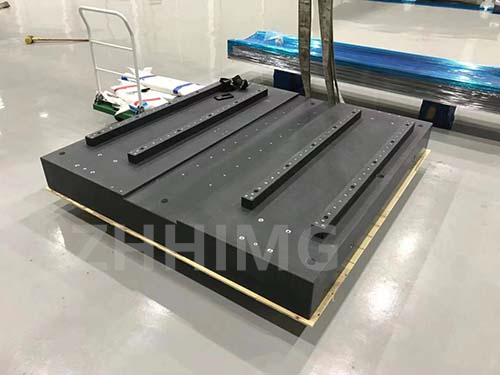

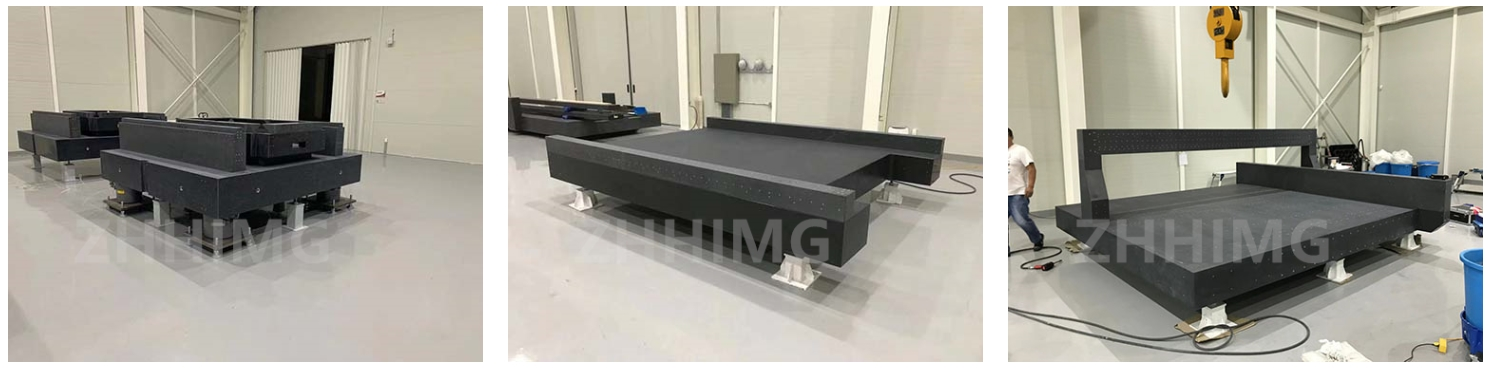

Ii. Daidaita Daidaito: Ta yaya Granite ke Biyan Bukatun Gine-gine daban-daban?

Yanayi na 1: Tsagi mai kyau sosai (ƙananan ramuka ƙasa da 10μm)

Bukatar: Mafi kyawun daidaito

Fa'idodin Granite: Ta hanyar haɗa ginshiƙai biyar masu daidaitaccen aiki, ana iya sarrafa lanƙwasa a cikin ±0.5μm/m, wanda ke nufin cewa a tsawon mita 1, kuskuren tsayin ya fi siririn gashin ɗan adam sau 200! Tabbatar cewa nisan da ke tsakanin kan mai yanke ginshiƙai da wafer koyaushe daidai ne, kuma faɗin ƙananan ginshiƙai da aka sassaka bai wuce ±0.1μm ba.

Yanayi na 2: Tsarin samar da kayan aiki mai sauri

Bukatar: Super shock absorption performance

Amfanin dutse: Abubuwan da ke cikinsa na halitta na danshi a ciki na iya rage girgizar kayan aiki cikin sauri. Bayan wani masana'anta na musamman ya gabatar da tushen dutse, saurin dasa dutse ya karu da kashi 40%, kuma yawan amfanin ƙasa ya tashi daga kashi 85% zuwa kashi 96%, wanda ya cimma nasarar girbin inganci da inganci sau biyu!

Yanayi na 3: Tsabtace muhalli mai rikitarwa (Zazzabi mai yawa/tsatsa)

Bukatu: Juriyar zafin jiki mai yawa da juriyar tsatsa

Amfanin granite: Ƙarfin daidaiton sinadarai mai ƙarfi, mai jure wa tsatsa ta acid da alkali; Yana da ƙarancin yawan faɗaɗa zafi kuma ba zai lalace ba ko da a yanayin zafi na gida (150℃) yayin da ake yin lanƙwasa laser. An ci gaba da amfani da tushen granite da aka yi amfani da shi a wani dakin gwaje-gwaje tare da maganin lanƙwasa mai lalata tsawon shekaru uku, kuma saman tushen yana nan lafiya.

Iii. Yadda Ake Zaɓar Tushen Granite Mai "Ainihin Inganci"?

Duba yawan duwatsun: Granite mai yawan ≥2800kg/m³ yana da tsari mai ƙanƙanta.

Duba takaddun shaida: Tabbatar da amincewa da takaddun shaida masu inganci kamar ISO 9001 da CNAS don tabbatar da inganci.

Bayanan tabbatarwa: Ana buƙatar masana'anta su bayar da rahotannin gwaji kan ma'aunin faɗaɗa zafi (< 8×10⁻⁶/℃) da kuma faɗin (±0.5μm/m).

Gwaji a wurin: Danna tushe. Sauti mai haske yana nuna cewa babu tsagewa a ciki. Idan saman taɓawa yana da santsi kamar madubi, yana nuna ingantaccen sarrafawa.

Kammalawa: Zaɓi dutse mai kyau kuma ku ci rabin yaƙin a cikin aikin tsagi!

Daga juriyar girgiza, juriyar zafi zuwa juriyar lalacewa, tushen granite, tare da "kyakkyawan halitta" da "ƙarfin tauri", ya zama abokin tarayya mai kyau ga kayan aikin wafer grooving. A zamanin yau na masana'antar semiconductor wanda ke bin daidaiton nanoscale, tushen granite mai inganci ba wai kawai saka hannun jari ne a cikin kayan aiki ba, har ma da garanti na dogon lokaci don ingancin samarwa da ingancin samfura!

Lokacin Saƙo: Yuni-17-2025