A fannin kera PCB (Printed Circuit Board), daidaiton haƙa ramin kai tsaye yana ƙayyade aikin lantarki da ƙimar yawan amfanin allon da'ira. Daga guntun wayoyin hannu zuwa allon da'ira na sararin samaniya, daidaiton kowane ramin micron yana da mahimmanci ga nasara ko gazawar samfurin. Tushen dutse, tare da halayen kayansu na musamman da fa'idodin tsarin su, suna zama "abokin tarayya na zinare" na kayan haƙa PCB, suna tura daidaiton masana'antar zuwa sabon tsayi.

I. Fa'idar Gaske: Aiki mai ƙarfi yana shimfida harsashin daidaito

Kwanciyar hankali mai kyau na zafi

A lokacin aikin haƙa PCB, zafi da juyawar babban gudu na injin haƙa ramin zai iya kaiwa 60-80℃. Faɗaɗa kayan ƙarfe na yau da kullun saboda zafi na iya sa matsayin haƙa ya canza cikin sauƙi. Matsakaicin faɗaɗa zafi na dutse shine 4-8×10⁻⁶/℃ kawai, wanda shine 1/5 na ƙarfe kawai. Wannan yana nufin cewa ko da zafin yanayi yana canzawa sosai, za a iya yin watsi da lalacewar tushen dutse. Bayan wani masana'anta na allon da'ira ya ɗauki tushen dutse, an rage kuskuren matsayin haƙa ramin daga ±50μm zuwa ±10μm, wanda hakan ya inganta daidaiton aikin lantarki na allon da'ira sosai.

2. Ƙarfin aikin girgizar ƙasa mai ƙarfi sosai

Girgizar injin haƙa rami mai yawan gaske a dubban juyawa a minti ɗaya na iya shafar tsaye na injin haƙa ramin, wanda ke haifar da karkacewar diamita na ramin. Halayen damshi na halitta a cikin granite suna ba shi damar shan fiye da kashi 90% na girgizar kayan aiki (20-50Hz). Bayanan da aka auna sun nuna cewa bayan shigar da tushen granite, girman girgizar injin haƙa ramin ya ragu daga 15μm zuwa 3μm, kuma ƙimar Ra na ƙaiƙayin bangon ramin da aka haƙa ramin ya ragu da kashi 60%, wanda hakan ya rage matsalolin burrs da wargajewar bangon ramin sosai.

3. Juriyar lalacewa mai ɗorewa

Hako PCB aiki ne mai yawan mita kuma yana da matuƙar buƙata don juriyar lalacewa na saman tushe. Granite yana da taurin Mohs na 6 zuwa 7 kuma juriyarsa ta ninka ta ƙarfe na yau da kullun sau uku. Babban masana'antar PCB ta ci gaba da amfani da tushen granite tsawon shekaru uku. Lalacewar saman bai wuce 0.01mm ba. Idan aka kwatanta da tushen ƙarfe, ana tsawaita zagayowar maye gurbin da sau biyu, wanda hakan ke rage farashin kula da kayan aiki yadda ya kamata.

Ii. Haɓaka Tsarin Aiki: Tsarin da aka keɓance yana haɓaka ingancin samarwa

Tushen duwatsun zamani, ta hanyar ingantaccen sarrafawa da sabbin tsare-tsare, suna ƙara haɓaka ƙimar amfani da su:

Tsarin sarrafa ma'aunin daidaitacce: Ta hanyar amfani da fasahar sarrafa lambobi masu haɗin kai guda biyar, ana sarrafa madaidaicin tushe a cikin ±0.5μm/m, yana samar da saman tunani mai faɗi sosai don kayan haƙa da kuma tabbatar da cewa kuskuren tsaye na ma'aunin haƙa ƙasa da 0.01°.

Tsarin shan girgizar zuma: Tsarin zumar ciki yana samar da rami mai zaman kansa, wanda ke cimma raguwar kuzarin girgiza mai matakai da yawa, kuma ya dace musamman don sarrafa ƙananan ramuka na 0.1mm ko ƙasa da haka.

Tashoshin sanyaya ruwa da aka riga aka saka: Don kayan haƙa mai ƙarfi, an shigar da tsarin sanyaya ruwa na ƙaramin tashar don sarrafa bambancin zafin jiki akan saman tushe a cikin ±0.5℃, wanda ke kawar da haɗarin lalacewar zafi gaba ɗaya.

Tsarin T-slot na musamman: An keɓance tazara da daidaiton T-slot (±0.01mm) bisa ga samfurin injin haƙa don cimma matsayi mai sauri da shigar da kayan aiki, wanda ke rage lokacin aiki na na'ura ɗaya da kashi 70%.

Iii. Shaidar Masana'antu: Inganta Inganci a Gani

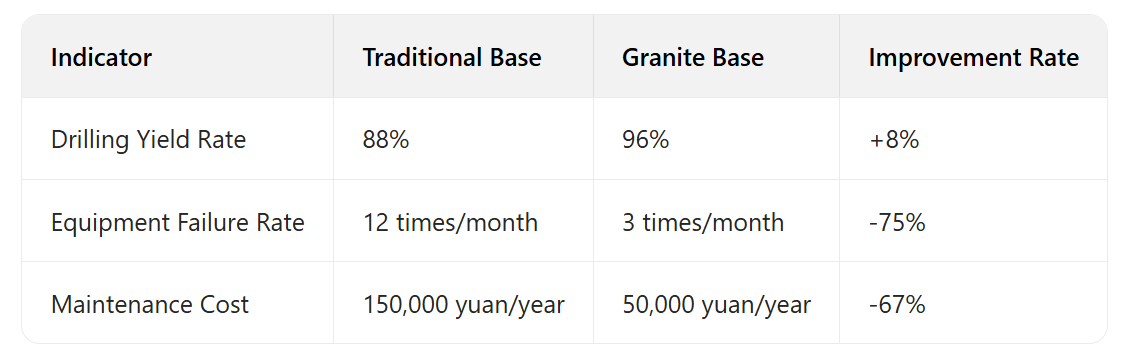

Bayan wani babban kamfanin PCB ya gabatar da sansanonin dutse, bayanan samar da shi sun sami ci gaba mai kyau:

Mafi mahimmanci, tushen dutse ya taimaka wa kamfanoni su shawo kan matsalolin fasaha, su yi nasarar yin odar ƙananan ramuka na 0.2mm ko ƙasa da haka, da kuma buɗe kasuwanni masu tsada.

iv. Fa'idodi Masu Dorewa: Zaɓi mai kyau don masana'antar kore

Granite dutse ne na halitta wanda ba shi da rufin sinadarai kuma ba shi da hayakin VOC, wanda ya cika ƙa'idodin kariyar muhalli na RoHS. Tsawon rayuwarsa mai tsawo yana rage yawan maye gurbin kayan aiki, yana rage yawan amfani da albarkatu da hayakin carbon. Wani lissafin hukumar kare muhalli ya nuna cewa amfani da tushen granite don na'urar haƙa PCB guda ɗaya na iya rage hayakin carbon da tan 3 a duk tsawon rayuwarsa, wanda ya yi daidai da yanayin canjin kore na masana'antar kera.

Daga tsarin sarrafa daidaito na matakin micron zuwa ingantaccen farashi mai cikakken tsari, sansanonin granite suna sake fasalin ka'idojin hanyoyin haƙa PCB tare da fa'idodin aiki marasa maye gurbinsu. A wannan zamanin da ake fama da buƙatar fashewar kwakwalwan 5G da AI, zaɓar tushen granite ba wai kawai saka hannun jari ne a cikin ingancin samfura ba, har ma da muhimmin mataki don ɗaukar babban matakin fasaha.

Lokacin Saƙo: Yuni-17-2025