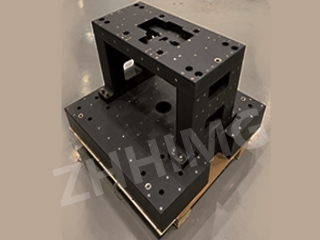

Granite sanannen abu ne da ake amfani da shi wajen gina kayan aikin daidaitacce na VMM (Injin auna hangen nesa) saboda taurinsa da kwanciyar hankalinsa. Taurin kayan aikin daidaitacce na granite yana taka muhimmiyar rawa wajen haɓaka aiki da daidaiton injunan VMM.

Taurin dutse yana tabbatar da cewa sassan daidaiton sun kasance masu karko kuma suna jure wa girgiza, wanda yake da mahimmanci don kiyaye daidaiton ma'auni a cikin injunan VMM. Wannan kwanciyar hankali yana da mahimmanci musamman lokacin gudanar da ma'auni da dubawa masu inganci, saboda kowane motsi ko girgiza na iya haifar da rashin daidaito a cikin sakamakon.

Bugu da ƙari, taurin sassan daidaiton dutse yana taimakawa wajen rage tasirin faɗaɗa zafi, wanda zai iya faruwa saboda canje-canje a zafin jiki a cikin yanayin VMM. Granite yana da ƙarancin ma'aunin faɗaɗa zafi, ma'ana ba ya saurin faɗaɗawa ko yin ƙunci tare da bambancin zafin jiki. Wannan halayyar tana tabbatar da cewa girman sassan daidaiton ya kasance daidai, yana ba da damar ma'auni masu inganci da maimaitawa.

Bugu da ƙari, taurin granite yana kuma taimakawa wajen dorewa da tsawon rai na injunan VMM. Ƙarfin yanayin granite yana tabbatar da cewa daidaiton sassan na iya jure amfani mai yawa da kuma kiyaye ingancin tsarin su akan lokaci, wanda ke rage buƙatar kulawa akai-akai da maye gurbinsu.

Dangane da aiki, taurin sassan daidaiton dutse yana bawa injunan VMM damar cimma manyan matakan daidaito da maimaitawa a ma'auninsu. Wannan yana da amfani musamman a masana'antu kamar su sararin samaniya, kera na'urorin mota, da na likitanci, inda ma'auni daidai suke da mahimmanci don tabbatar da inganci da amincin samfura.

A ƙarshe, taurin sassan daidaiton granite yana da matuƙar amfani ga injunan VMM ta hanyar samar da kwanciyar hankali, juriya ga girgiza, da kuma rage tasirin faɗaɗa zafi. Waɗannan halaye a ƙarshe suna ba da gudummawa ga daidaito, aminci, da tsawon rai na injunan VMM, wanda hakan ya sanya su kayan aiki mai mahimmanci don sarrafa inganci da hanyoyin dubawa a masana'antu daban-daban.

Lokacin Saƙo: Yuli-02-2024