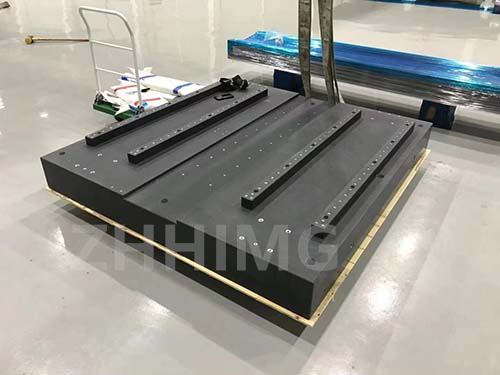

Granite sanannen abu ne da ake amfani da shi wajen yin sassa masu daidaito saboda dorewarsa da kuma juriyarsa ga lalacewa da tsagewa. Kammalawar saman sassan daidai gwargwado na granite yana taka muhimmiyar rawa wajen tantance ingancin hoton na'urar VMM (Na'urar auna gani).

Ƙarshen saman sassan daidaiton dutse yana nufin laushi da santsi na saman. Ana samunsa ta hanyar matakai kamar niƙa, gogewa, da lapping. Ingancin ƙarewar saman yana shafar aikin injin VMM ta hanyoyi da dama.

Da farko, kammala saman da ya yi santsi da daidaito yana da mahimmanci don tabbatar da daidaito da daidaiton ma'auni. Duk wani rashin daidaito ko rashin ƙarfi a saman ɓangaren granite na iya haifar da karkacewar hoton da injin VMM ya kama, wanda ke haifar da ma'auni marasa daidaito da kuma rashin ingancin da aka yi amfani da shi.

Bugu da ƙari, ƙarshen saman sassan daidai gwargwado na granite na iya shafar ikon injin VMM na ɗaukar cikakkun bayanai da fasaloli masu kyau. Kyakkyawan ƙarewar saman yana ba da damar ɗaukar hoto mai haske da kaifi, wanda ke ba injin VMM damar yin nazarin yanayin ƙasa da girman ɓangaren daidai.

Bugu da ƙari, kammala saman yana kuma tasiri ga daidaito da kuma sake maimaitawa na na'urar VMM. Tsarin dutse mai kyau yana samar da dandamali mai karko da daidaito ga ɓangaren da ake aunawa, yana rage girgiza da kuma tabbatar da sakamako mai inganci da maimaituwa.

A ƙarshe, ƙarshen saman sassan daidaiton dutse yana tasiri sosai ga ingancin hoton injin VMM. Yana da mahimmanci a kula da ƙarshen saman yayin aikin ƙera don tabbatar da mafi girman matakin daidaito da daidaito a cikin ma'auni. Ta hanyar cimma kyakkyawan ƙarewar saman, masana'antun za su iya inganta aikin injinan VMM da haɓaka ingancin sarrafa sassan daidaito.

Lokacin Saƙo: Yuli-02-2024