A fannin kera semiconductor mai cikakken daidaito, ko da ƙaramin girgiza zai iya yin tasiri sosai ga aikin injinan wafer slotting, wanda ke haifar da lahani da asarar yawan amfanin ƙasa. Tushen injinan granite sun fito a matsayin mafita mai canzawa, suna ba da damar rage girgiza mara misaltuwa - wanda ke da mahimmanci don kiyaye amincin sarrafa wafer.

Yawan Yawa da Rashin Inganci Don Dakatar da Girgizawa

Yawan girman dutse mai girman granite, yawanci daga 2,600 zuwa 3,100 kg/m³, yana samar da isasshen kuzari. Idan aka haɗa shi cikin injunan rami mai girman wafer, wannan halayyar tana tsayayya da girgizar waje yadda ya kamata. Misali, a cikin bene mai cike da kayan aiki na semiconductor, injinan da ke kewaye da su da zirga-zirgar ƙafa na iya haifar da girgizar yanayi. Tushen injin granite, tare da nauyinsa mai yawa, yana aiki azaman tushe mai ƙarfi, yana rage watsa waɗannan girgizar zuwa ga sassan injin rami mai laushi. Sakamakon haka, kayan aikin yankewa suna kasancewa daidai a wurin, suna rage haɗarin yankewa da aka yi niyya da kuma inganta ingancin wafers ɗin ramin.

Girgizar Halitta - Damfara Halayen Damfara

Tsarin ciki na musamman na granite, wanda ya ƙunshi ƙwayoyin ma'adinai masu haɗaka, yana ba shi damar yin rawar jiki da damshi mai kyau. Lokacin da injin wafer ya yi aiki, juyawa mai sauri na kayan aikin yankewa da ƙarfin injin da ke tattare da shi na iya haifar da girgizar ciki. Granite yana sha kuma yana wargaza wannan kuzarin girgiza, yana hana shi yin rawar jiki ta cikin tsarin injin. Ba kamar tushen ƙarfe ba waɗanda za su iya ƙara girgiza, tasirin damshin granite na halitta yana tabbatar da cewa injin yana aiki cikin sauƙi. Bincike ya nuna cewa amfani da tushen granite na iya rage girman girgiza har zuwa 70%, wanda ke ba injin ramin damar kiyaye babban matakin daidaito yayin aikin yankewa.

Kwanciyar Hankali Don Hana Girgizawa - Kurakurai da Aka Jawo

Sauye-sauyen zafin jiki a yanayin masana'antu na iya haifar da faɗaɗawa ko ƙunƙulewa, wanda ke haifar da rashin daidaito da kuma girgiza daga baya. Granite yana da ƙarancin yawan faɗaɗa zafi, ma'ana yana kiyaye siffarsa da girmansa ko da a ƙarƙashin yanayin zafi daban-daban. A cikin injin ramin wafer, wannan kwanciyar hankali na zafi yana da mahimmanci. Misali, a lokacin tsawaita aikin samarwa, injin na iya zafi saboda ci gaba da aiki. Tushen granite yana tabbatar da cewa sassan injin ɗin suna cikin daidaito daidai, yana guje wa duk wani girgiza da zafi ya haifar ko canje-canje na girma wanda zai iya shafar daidaiton ramin wafer. Wannan kwanciyar hankali yana taimakawa wajen tabbatar da daidaiton inganci a duk wafers da aka sarrafa.

Tushen Tsauri da Ƙarfi don Daidaito

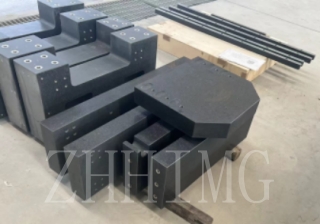

Taurin granite wani muhimmin abu ne wajen rage girgiza. Tsarinsa mai ƙarfi yana samar da tushe mai ƙarfi ga injin wafer slotting, yana hana duk wani motsi ko lanƙwasawa da ba a so. Daidaito - saman ƙasa na tushen injin granite kuma yana ba da damar shigar da kayan injin daidai, yana ƙara inganta kwanciyar hankali. Lokacin da aka ɗora injin da ƙarfi a kan tushen granite, yana iya aiki a babban gudu tare da ƙarancin girgiza, yana ba da damar saurin sarrafa lokaci ba tare da lanƙwasa daidaito ba.

Labarun Nasara na Gaske - Duniya

A cikin wani babban masana'antar kera na'urorin semiconductor, amfani da tushen injinan granite a cikin injinan wafer ya haifar da ingantaccen ci gaba a ingancin samarwa. Abubuwan da ke rage girgiza na granite sun rage faruwar ƙananan karyewar a cikin wafers ɗin da aka slotted, wanda ya ƙara yawan amfanin ƙasa daga 85% zuwa 93%. Bugu da ƙari, ingantaccen kwanciyar hankali ya ba da damar ƙaruwa da kashi 20% a cikin saurin aiki na injin, wanda ya haɓaka yawan aiki gaba ɗaya.

A ƙarshe, tushen injinan granite suna taka muhimmiyar rawa wajen rage girgiza a cikin injinan wafer slotting. Babban yawansu, halayen girgiza - damping, kwanciyar hankali na zafi, da tauri suna haɗuwa don ƙirƙirar yanayi mai karko da daidaito na aiki. Ga masana'antun semiconductor da ke da niyyar inganta inganci da ingancin sarrafa wafer ɗinsu, saka hannun jari a cikin tushen injinan granite mafita ce da aka tabbatar kuma mai tasiri.

Lokacin Saƙo: Yuni-12-2025