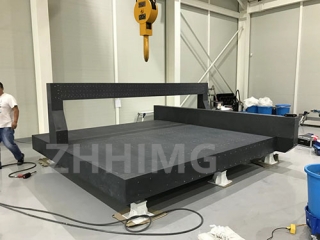

IA masana'antar kera na'urorin semiconductor, daidaiton kayan aikin duba wafer yana da matuƙar muhimmanci don tabbatar da ingancin da'irori masu haɗawa. Tushen injinan granite masu inganci, kamar waɗanda ZHHIMG® ke bayarwa, suna taka muhimmiyar rawa wajen haɓaka aikin irin waɗannan kayan aikin. Ga yadda suke kawo canji.

Daidaito Mai Girma Na MusammanGranite yana da ƙarancin ma'aunin faɗaɗa zafi, kusan (4-8) × 10⁻⁶/℃, ƙasa da ƙarfe da yawa. A cikin yanayin da masana'antun semiconductor ke sarrafawa sosai, inda ko da ƙananan canjin zafin jiki na iya haifar da kurakuran aunawa, tushen injin granite suna da ƙarfi. Wannan kwanciyar hankali yana tabbatar da cewa sanya abubuwan da ke cikin kayan aikin duba wafer ya kasance daidai, yana hana duk wani karkacewa da zafi ke haifarwa wanda zai iya shafar daidaiton sakamakon dubawa.

Babban Damfarar Girgiza Bene-bene na samarwa galibi suna cike da girgiza daga tushe daban-daban. Sifofin damfarar da ke cikin granite, tare da rabon damfarar 0.05–0.1, suna sha da kuma wargaza waɗannan girgizar yadda ya kamata. Don insp ɗin wafer

Sashen, wanda ke buƙatar ɗaukar hoto mai ƙuduri mai girma da kuma karanta firikwensin daidai, raguwar girgizar da tushen granite ke bayarwa yana da matuƙar muhimmanci. Yana rage tsangwama da zai iya ɓata hotuna ko ɓatar da bayanan firikwensin, yana ba kayan aikin damar ɗaukar bayanai bayyanannu da sahihanci game da saman wafer da tsarin ciki.

Babban Tauri da Juriyar Sawa Tare da yawan da ya kai kimanin kg 3100/m³, sansanonin injinan granite na ZHHIMG® suna ba da tauri mai ban mamaki. Suna iya tallafawa manyan sassan kayan aikin duba wafer ba tare da canza tsari ba, suna kiyaye daidaiton tsarin gani da na inji. Bugu da ƙari, babban tauri na granite (ma'aunin Mohs 6-7) da kuma kyakkyawan juriyar sawa suna tabbatar da cewa saman tushen injin ya kasance mai faɗi da santsi akan lokaci. Wannan daidaito yana da mahimmanci don daidaito na dogon lokaci, kamar yadda duk wani lalacewa ko nakasa a kan tushe zai iya lalata daidaiton kayan aikin a hankali.

Sinadaran Rashin Nauyi Kera semiconductor ya ƙunshi fallasa ga sinadarai daban-daban. Rashin nauyi na sinadarai na granite yana sa shi ya yi tsayayya da tsatsa daga waɗannan abubuwa. Wannan siffa tana kare mutuncin tushen injin, tana hana lalacewar da sinadarai ke haifarwa wanda zai iya shafar daidaito da daidaiton kayan aikin dubawa.

A ƙarshe, tushen injinan granite masu inganci ba wai kawai wani ɓangare bane, har ma wani muhimmin abu ne don cimma daidaiton buƙatun kayan aikin duba wafer. Lokacin zabar tushen injinan granite, zaɓi masu samar da kayayyaki masu aminci kamar ZHHIMG®. Tare da takaddun shaida da yawa da kuma jajircewa ga inganci, ZHHIMG® yana tabbatar da cewa kowane tushen injinan granite yana ba da aminci da aikin da ake buƙata don ƙera semiconductor mai ci gaba.

Lokacin Saƙo: Yuni-03-2025