A cikin madaidaicin masana'anta da ilimin awo, dutsen granite shine ginshiƙin da ba a gardama ba- ma'anar sifili don auna girma. Ƙarfinsa na riƙe da cikakken jirgin sama ba dabi'a ce kawai ba, amma sakamakon tsarin sarrafa tsari sosai, yana biye da horo, kulawa na yau da kullun. Amma menene madaidaicin tafiya da dutsen dutsen dutse ya ɗauka don cimma irin wannan kamala, kuma waɗanne ka'idoji ne suka wajaba don kiyaye ta? Ga injiniyoyi da manajoji masu inganci, fahimtar duka asalin wannan madaidaicin da matakan da suka wajaba don kiyaye shi yana da mahimmanci ga kiyaye ingancin masana'anta.

Sashe na 1: Tsarin Siffar-Tsarin Injiniya

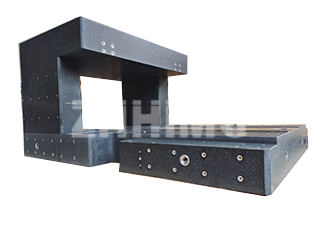

Tafiya na dutsen dutsen dutse, daga ƙaƙƙarfan shinge zuwa faranti mai daraja, ya ƙunshi jerin niƙa, daidaitawa, da matakan ƙarewa, kowanne an tsara shi don rage kuskuren girma.

Da farko, bayan yankan, ana yin ginshiƙan da Ƙaƙƙarfan Siffatawa da Niƙa. Wannan matakin yana kawar da abubuwa masu yawa don tabbatar da madaidaicin lissafi na ƙarshe da m flatness. Mahimmanci, wannan tsari kuma yana ba da gudummawa don sakin yawancin abubuwan da ke haifar da damuwa da ke tasowa a cikin dutse yayin sassaƙawa da yankewar farko. Ta hanyar ƙyale slab ɗin don "zama" kuma ya sake daidaitawa bayan kowane babban matakin cire kayan, muna hana ɗimbin girma na gaba, tabbatar da kwanciyar hankali na dogon lokaci.

Canji na gaskiya yana faruwa a lokacin The Art of Precision Lapping. Lapping shi ne na ƙarshe, tsari na musamman wanda ke sake fasalin ƙasa mai ɗan lebur cikin ingantacciyar jirgin sama. Wannan ba inji ba ne; aiki ne mai ƙwazo, ƙananan sauri, aiki mai ƙarfi. Muna amfani da lallausan mahadi masu ɓarna - galibi slurry lu'u-lu'u - an dakatar da su a cikin matsakaicin ruwa, ana amfani da shi tsakanin saman dutsen da tsayayyen farantin ƙarfe na simintin gyare-gyare. Ana sarrafa motsi a hankali don tabbatar da cire kayan iri ɗaya a saman saman. Wannan matsakaicin sakamako, maimaituwa da hannu da injina a cikin matakan juzu'i, a hankali yana sake daidaita daidaituwa zuwa cikin microns ko ma ƙananan ƙananan microns (gamuwa da ƙayyadaddun ƙa'idodi kamar ASME B89.3.7 ko ISO 8512). Madaidaicin da aka samu anan ya kasance ƙasa da na'ura da ƙari game da ƙwarewar ma'aikacin, wanda muke kallo a matsayin sana'a mai mahimmanci, wadda ba za a iya maye gurbinsa ba.

Sashe na 2: Kulawa — Maɓalli don Dorewar Gaskiya

Farantin granite kayan aiki daidai ne, ba kayan aiki ba. Da zarar an tabbatar da shi, ikonsa na kiyaye daidaito ya dogara gaba ɗaya akan ka'idojin mai amfani da muhalli.

Kula da muhalli shine mafi girman al'amari guda ɗaya wanda ke shafar daidaiton granite. Duk da yake granite yana da ƙarancin haɓakar haɓakar thermal (COE), bambancin zafin jiki tsakanin saman sama da ƙasa (ƙawan yanayin zafin jiki na tsaye) na iya haifar da tudun gabaɗaya zuwa kubba ko warp. Sabili da haka, dole ne a kiyaye farantin daga hasken rana kai tsaye, daftarin sanyaya iska, da matsanancin zafi. Kyakkyawan yanayi yana kula da barga 68°F ± 1°F (20℃ ± 0.5℃).

Game da Yarjejeniyar Amfani da Tsaftacewa, ci gaba da amfani da gida yana haifar da rashin daidaituwa. Don magance wannan, muna ba da shawara lokaci-lokaci a jujjuya slab akan tsayawarsa da rarraba ayyukan ma'auni a duk faɗin saman. tsaftacewa na yau da kullun wajibi ne. Kura da tarkace masu kyau suna aiki azaman abrasives, suna hanzarta lalacewa. Ya kamata a yi amfani da masu tsabtace granite na musamman, ko barasa isopropyl mai tsafta. Kada a taɓa amfani da wanki na gida ko masu tsabtace ruwa wanda zai iya barin rago mai ɗaki ko, a yanayin ruwa, ɗan ɗan yi sanyi da karkatar da ƙasa. Lokacin da farantin yana aiki, dole ne a rufe shi da tsabta, mai laushi, mara lahani.

A ƙarshe, game da Recalibration da Sabuntawa, ko da tare da cikakkiyar kulawa, babu makawa lalacewa. Ya danganta da darajar amfani (misali, Grade AA, A, ko B) da nauyin aiki, dole ne a sake daidaita farantin granite a bisa ƙa'ida kowane watanni 6 zuwa 36. ƙwararren ƙwararren masani yana amfani da kayan aiki kamar autocollimators ko Laser interferometers don taswirar karkatacciyar ƙasa. Idan farantin ya faɗi a waje da ƙimar haƙurinsa, ZHHIMG yana ba da sabis na sake latsawa ƙwararru. Wannan tsari ya haɗa da dawo da madaidaicin ƙafar baya a kan rukunin yanar gizon ko zuwa wurin aikinmu don maido da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aikin.

Ta hanyar fahimtar babban tsari na siffatawa da kuma ƙaddamar da tsarin kulawa mai tsauri, masu amfani za su iya tabbatar da cewa faranti na granite ya kasance tabbataccen tushe don duk ainihin buƙatun ingancin su, shekaru goma bayan shekaru goma.

Lokacin aikawa: Oktoba-24-2025