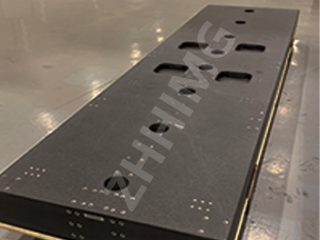

Ana amfani da kayan aikin CNC sosai a masana'antar zamani, kuma amfani da tallafi mai ƙarfi da dorewa kamar gadon granite sau da yawa shine zaɓi mafi kyau don yin aikin daidai. Duk da haka, faɗaɗa zafi na iya haifar da matsalolin daidaito lokacin amfani da gadon granite don kayan aikin CNC, musamman a cikin yanayin zafi mai yawa. Wannan labarin yana da nufin samar da wasu shawarwari masu amfani kan yadda za a guji matsalolin daidaito da faɗaɗa zafi ke haifarwa lokacin amfani da gadon granite don kayan aikin CNC.

Da farko, yana da mahimmanci a zaɓi kayan granite masu inganci tare da ƙarancin ƙimar faɗaɗa zafi. Matsakaicin faɗaɗa zafi na granite ya bambanta dangane da nau'in da asalin kayan, kuma yana da tasiri mai mahimmanci akan daidaiton injinan CNC. Saboda haka, ana ba da shawarar a zaɓi granite mai ƙarancin ƙimar faɗaɗa zafi, kamar baƙar dutse daga China ko Indiya, wanda ke da ƙimar faɗaɗa zafi na kusan 4.5 x 10^-6 / K.

Na biyu, yana da mahimmanci a kula da zafin yanayin da kayan aikin CNC ke aiki. Ya kamata zafin ɗakin da aka sanya gadon granite ya kasance mai daidaito kuma mai daidaito. Duk wani canji kwatsam a zafin jiki na iya haifar da faɗaɗa zafi ko raguwa, wanda ke haifar da kurakurai a cikin daidaiton injin. Saboda haka, ana ba da shawarar a samar wa kayan aikin CNC tsarin kula da zafin jiki wanda zai iya kiyaye zafin ɗakin a matakin da ya dace.

Abu na uku, yana da mahimmanci a zaɓi hanyar shafa man shafawa mai dacewa ga gadon granite. Yayin da zafin jiki ke canzawa, danko na man shafawa da ake amfani da shi a gadon granite shi ma zai canza, wanda zai shafi aikin kayan aikin CNC. Saboda haka, ana ba da shawarar amfani da man shafawa wanda yake da karko a yanayin zafi daban-daban kuma zai iya rage tasirin faɗaɗa zafi akan gadon granite.

A ƙarshe, yana da mahimmanci a riƙa duba da kuma kula da gadon granite akai-akai domin tabbatar da daidaito da daidaitonsa. Duk wani rashin daidaito ko lahani a gadon granite na iya haifar da matsalolin daidaito a cikin injinan CNC. Don haka, ana ba da shawarar a riƙa yin dubawa akai-akai da kuma kula da gadon granite don gano da kuma gyara duk wata matsala kafin su shafi daidaiton injinan.

A ƙarshe, amfani da gadon granite don kayan aikin CNC na iya samar da kyakkyawan kwanciyar hankali da daidaito a cikin injina. Duk da haka, tasirin faɗaɗa zafi akan gadon granite na iya haifar da matsalolin daidaito, wanda ke shafar ingancin injinan CNC. Saboda haka, yana da mahimmanci a zaɓi babban dutse mai inganci tare da ƙarancin ƙimar faɗaɗa zafi, a kula da zafin muhalli, a zaɓi hanyar shafa mai dacewa, da kuma dubawa akai-akai da kula da gadon granite don guje wa matsalolin daidaito da faɗaɗa zafi ke haifarwa.

Lokacin Saƙo: Maris-29-2024