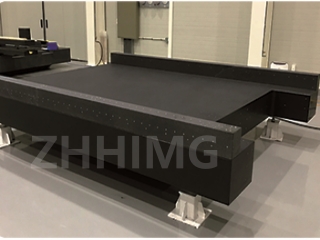

Idan ya zo ga ainihin mashin ɗin, mahimmancin zaɓin farantin gwajin granite daidai don injin CNC ɗin ku ba za a iya faɗi ba. Waɗannan faranti suna aiki azaman tsayayye da lebur don aunawa da duba sassan injinan, tabbatar da daidaito da inganci a samarwa. Anan akwai wasu mahimman abubuwan da za ku yi la'akari yayin zabar farantin binciken granite daidai don injin CNC ɗin ku.

1. Girma da Kauri: Girman farantin granite ya kamata ya dace da girman ɓangaren da ake dubawa. Manyan faranti suna ba da ƙarin sarari aiki, yayin da faranti masu kauri suna ba da kwanciyar hankali da juriya ga warping. Yi la'akari da nauyin injin CNC da kuma ɓangaren da ake aunawa don ƙayyade kauri mai dacewa.

2. Lalacewar Sama: Lalacewar dutsen granite yana da mahimmanci don auna daidai. Nemi tulun da ya dace da ma'aunin masana'antu don daidaitawa, yawanci ana auna shi da microns. Babban ingancin granite dubawa slabs za su sami kwanciyar hankali haƙuri wanda ke tabbatar da daidaito da ingantaccen sakamako.

3. Material Quality: Ba duk granite aka halitta daidai. Zaɓi babban dutsen dutse mai yawa wanda ba shi da sauƙi ga guntu da lalacewa. Ingancin granite zai shafi rayuwar kai tsaye da aikin kwamitin dubawa.

4. Cindarma ta ƙare: farfajiya ta karewa mafi girman dutsen yana shafar matsakaicin kayan aikin auna da sauƙi tsabtatawa. Ana fifita filaye masu gogewa sau da yawa don santsi da sauƙin kulawa.

5. Na'urorin haɗi da Features: Yi la'akari da ƙarin fasalulluka kamar T-ramummuka don matsawa, daidaita ƙafafu don kwanciyar hankali, da wadatar sabis na daidaitawa. Waɗannan na iya haɓaka aikin farantin binciken granite ɗinku.

A taƙaice, zabar farantin dubawa mai kyau don injin CNC ɗinku yana buƙatar yin la'akari da hankali na girman, ɗabi'a, ingancin kayan, ƙarewar ƙasa, da sauran fasalulluka. Ta zaɓin farantin da ya dace, zaku iya tabbatar da ingantattun ma'auni da haɓaka ingantaccen aikin injin ku.

Lokacin aikawa: Dec-23-2024