A fagen masana'antar wafer semiconductor, zaɓin kayan tushe kai tsaye yana shafar daidaiton kayan aiki da yawan amfanin ƙasa. Wasu masu ba da kaya marasa gaskiya sun wuce marmara a matsayin granite na halitta, suna wucewa da ƙananan kayayyaki a matsayin masu kyau. Kwarewar hanyoyin ganowa na biyu shine mabuɗin don tabbatar da tsayayyen aiki na kayan wafer. Wannan labarin ya rushe bambance-bambance daga manyan girma huɗu don taimaka muku guje wa tarko na maye gurbin marasa inganci.

I. Dinsity da Hardness: Mafi Ilhamar Jiki "Katin ID"

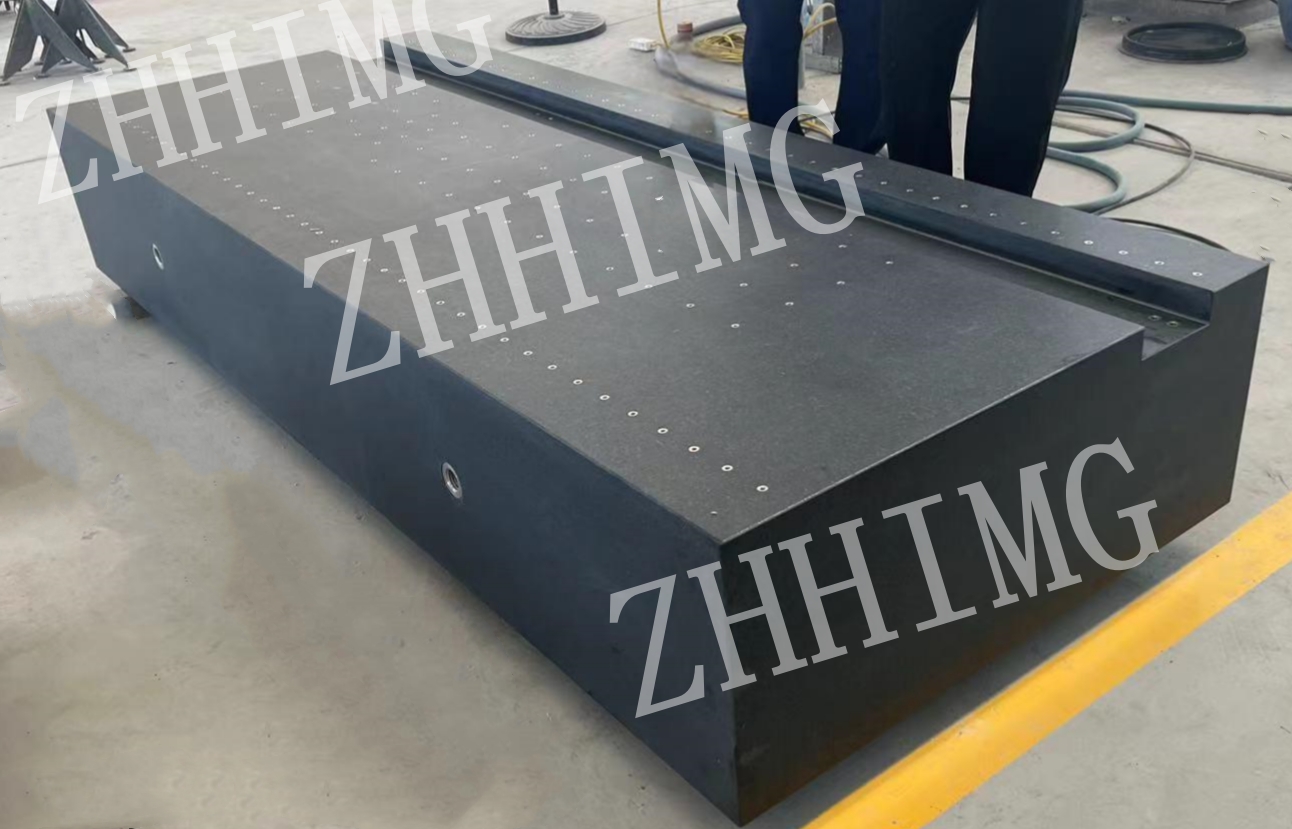

Granite na halitta: Tare da yawa na 2600-3100kg/m³, taurin Mohs na 6-7, da sauti mai haske lokacin da aka buge shi. Baƙar granite da ZHHIMG® ya zaɓa yana da nauyi sama da 3000kg/m³ kuma yana iya jure nauyi iri ɗaya sama da 1000kg/m².

Marmara: Tare da yawa kawai 2500-2700kg/m³, taurin 3-5, da sauti maras ban sha'awa lokacin da aka buga. Idan a hankali ka karce saman da tsabar kudin, marmara yana da wuyar barin alamomi, yayin da granite ya kusan lalacewa.

Ii. Halayen Tsari: "Labarai" Karkashin Ma'auni

Granite na halitta: Ya ƙunshi barbashi na ma'adinai irin su ma'adini da feldspar waɗanda ke kusa da juna, tare da porosity na ƙasa da 0.5%. Gwajin Ultrasonic ba ya nuna a fili aibi na ciki.

Marmara: Babban bangarensa shine calcium carbonate, tare da tsarin sikirin kristal, porosity na 1-3%, kuma yana da wuyar sha ruwa da fadadawa. A cikin yanayin zafi mai zafi na kayan aikin wafer, tushen marmara na iya haifar da madaidaicin karkata fiye da ± 5μm saboda haɓakar thermal da haɓaka.

Iii. Gwajin Aiki: "Madubin Sihiri" a cikin Yaƙin Gaskiya

Iv. Tabbatarwa da Ganewa: Dogaran "Tabbacin Shaida"

Tushen granite na yau da kullun: ISO 9001 ingancin takaddun shaida da rahoton gwajin abun da ke cikin ma'adinai na SGS ana ba da su, kuma ana iya gano asalin jijiya mai ma'adinai (kamar Jinan Black, Shandong, Baƙar fata Indiya).

Madogara mara inganci: Ba tare da takaddun shaida ba, ko siffanta su a matsayin "kayan granite", a zahiri rina marmara ne kuma ba za su iya samar da cikakkun bayanan gwaji ba.

Jagoran Gujewa Matsaloli: Dabaru Uku Don Kiyaye Tushe Mai Kyau

Bincika takaddun shaida: Bukatar mai siyarwa don gabatar da rahotannin gwaji na yawa, tauri da haɓakar haɓakar thermal;

Gwajin gwaji: Yi kwaikwayon yanayin aiki na kayan aikin wafer don gwada kwanciyar hankali na tushe a ƙarƙashin girgiza da canje-canjen zafin jiki;

Lokacin zabar alama, ba da fifiko ga masana'antun irin su ZHHIMG® waɗanda suka wuce takaddun tsarin tsarin ISO uku don guje wa tarko mai ƙarancin farashi na ƙananan tarurrukan.

Lokacin aikawa: Juni-10-2025