A cikin fagage kamar masana'anta na semiconductor da ingantattun kayan aunawa, daidaiton matakan madaidaicin granite yana ƙayyade ingancin aikin kayan aiki kai tsaye. Don tabbatar da cewa daidaiton dandamali ya cika ka'idoji, ya kamata a yi ƙoƙari daga bangarori biyu: gano mahimman alamomi da bin ƙa'idodi. ;

Gano mai nuna alama: Multi-girma iko na daidaito

Gano kwanciyar hankali: Ƙayyade "lalata" na jirgin sama

Flatness shine ainihin ma'anar madaidaicin dandamali na granite, kuma yawanci ana auna shi ta hanyar interferometers na Laser ko matakan lantarki. Interferometer na Laser na iya auna daidai ƙarancin minti kaɗan a saman dandamali ta hanyar fitar da katako na Laser da amfani da ƙa'idar tsangwama ta haske, tare da daidaito ya kai matakin ƙananan micron. Matsayin lantarki yana auna ta hanyar motsawa sau da yawa kuma yana zana taswirar kwane-kwane mai girma uku na farfajiyar dandamali don gano ko akwai wani firgici na gida ko damuwa. Misali, dandali na granite da ake amfani da su a cikin injunan hoto na semiconductor ana buƙatar samun daidaiton ± 0.5μm/m, ma'ana cewa bambancin tsayi tsakanin tsayin mita 1 bai kamata ya wuce rabin micrometer ba. Ta hanyar ingantattun kayan aikin ganowa ne kawai za'a iya tabbatar da wannan tsayayyen ma'auni. ;

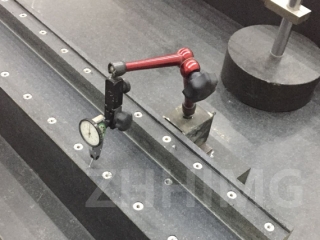

2. Gano madaidaiciya: Tabbatar da "daidaita" motsi na layi

Don dandamali waɗanda ke ɗaukar daidaitattun sassa masu motsi, madaidaiciya yana da mahimmanci. Hanyoyin da ake amfani da su don ganowa sune hanyar waya ko na'ura mai sarrafa Laser. Hanyar waya ta ƙunshi dakatar da madaidaicin madaidaicin wayoyi na ƙarfe da kwatanta rata tsakanin farfajiyar dandamali da wayoyi na ƙarfe don sanin madaidaiciyar. Laser collimator yana amfani da sifofin yaɗuwar layin layi na Laser don gano kuskuren madaidaiciyar saman shigarwa na layin jagorar dandamali. Idan madaidaicin bai dace da ma'auni ba, zai haifar da kayan aiki don motsawa yayin motsi, yana shafar daidaiton sarrafawa ko aunawa. ;

3. Gano rashin ƙarfi na saman: Tabbatar da "lafiya" na lamba

Ƙaƙƙarfan yanayin dandali yana rinjayar dacewa da shigar da kayan aiki. Gabaɗaya, ana amfani da mitar roughness stylus ko na'urar hangen nesa don ganowa. Nau'in kayan aiki na stylus yana yin rikodin canje-canjen tsayin bayanan martabar ƙanƙanta ta hanyar tuntuɓar saman dandamali tare da bincike mai kyau. Na'urorin gani na gani na iya lura da rubutun saman kai tsaye. A cikin aikace-aikacen madaidaicin madaidaici, ana buƙatar sarrafa yanayin saman dandamali na granite a Ra≤0.05μm, wanda yayi daidai da tasirin madubi, tabbatar da cewa daidaitattun abubuwan da suka dace sun dace sosai yayin shigarwa da guje wa rawar jiki ko ƙaura ta hanyar gibba. ;

Matsakaicin madaidaicin sun biyo baya: ƙa'idodin ƙasa da ƙasa da sarrafa cikin gida na kamfani

A halin yanzu, a duniya, ana amfani da ka'idodin ISO 25178 da GB/T 24632 azaman tushen ƙayyadaddun daidaiton dandamali na dutse, kuma akwai bayyanannun rarrabuwa don alamomi kamar lebur da madaidaiciya. Bugu da kari, manyan masana'antun masana'antu galibi suna saita mafi tsauraran matakan sarrafawa na ciki. Misali, abin da ake buƙata na shimfidar wuri don dandalin granite na injin photolithography shine 30% sama da daidaitattun ƙasashen duniya. Lokacin gudanar da gwaje-gwaje, ya kamata a kwatanta bayanan da aka auna tare da ma'auni masu dacewa. Sai kawai dandamali waɗanda ke cika cikar ƙa'idodi za su iya tabbatar da ingantaccen aiki a ainihin kayan aiki. ;

Duban daidaiton matakan granite madaidaicin tsari ne na tsari. Sai kawai ta hanyar gwada ainihin ma'anoni irin su flatness, straightness, da surface roughness, da mannewa ga kasa da kasa da kuma sha'anin matsayin, za a iya tabbatar da babban daidaito da amincin dandali, aza m harsashi ga high-karshen masana'antu filayen kamar semiconductor da daidaitattun kayan aiki.

Lokacin aikawa: Mayu-21-2025