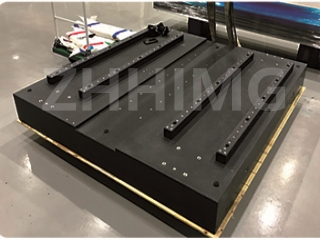

Granite yana ɗaya daga cikin kayan da aka fi amfani da su don tushen kayan aikin injin CNC saboda kyakkyawan juriyarsa, kwanciyar hankali, da daidaito. Duk da haka, girgiza da hayaniya na iya faruwa yayin aikin injinan CNC, wanda zai iya yin mummunan tasiri ga aiki da daidaiton injin. A cikin wannan labarin, za mu tattauna wasu hanyoyin rage girgiza da hayaniya lokacin da ake amfani da tushen granite don kayan aikin injin CNC.

1. Shigarwa Mai Kyau

Ɗaya daga cikin muhimman abubuwan da za a yi la'akari da su yayin amfani da tushen granite don kayan aikin injin CNC shine shigarwa mai kyau. Dole ne a daidaita tushen granite kuma a ɗaure shi sosai a ƙasa don hana duk wani motsi da zai iya haifar da girgiza. Lokacin shigar da tushen granite, ana iya amfani da ƙusoshin anga ko epoxy grout don ɗaure shi zuwa ƙasa. Ya kamata kuma a duba tushen lokaci-lokaci don tabbatar da cewa ya kasance daidai kuma amintacce.

2. Tabarmar Keɓewa

Wata hanya mai inganci don rage girgiza da hayaniya ita ce amfani da tabarmar keɓewa. An tsara waɗannan tabarmar don shan girgiza da girgiza kuma ana iya sanya su a ƙarƙashin injin don rage watsa girgiza zuwa ƙasa da kewaye. Amfani da tabarmar keɓewa na iya inganta aiki da daidaiton injin sosai yayin da ake rage hayaniyar da ba a so.

3. Damping

Damping wata dabara ce da ta ƙunshi ƙara kayan aiki a cikin injin don rage girgiza da hayaniya da ba a so. Ana iya amfani da wannan dabarar a kan tushen granite ta amfani da kayan aiki kamar roba, abin toshe kwalaba, ko kumfa. Ana iya sanya waɗannan kayan tsakanin tushe da injin don rage girgiza da hayaniya. An tsara su kuma aka sanya kayan damshi yadda ya kamata zai iya rage faruwar mitoci masu ƙarfi waɗanda za su iya haifar da girgiza a cikin injin.

4. Kayan aiki masu daidaito

Daidaitaccen kayan aiki yana da mahimmanci don rage girgiza da hayaniya. Dole ne a daidaita masu riƙe kayan aiki da madaurin kayan aikin injin CNC don guje wa girgiza mai yawa yayin aiki. Rashin daidaiton kayan aiki na iya haifar da girgiza mai yawa wanda zai iya yin mummunan tasiri ga aiki da daidaiton injin. Kula da tsarin kayan aiki mai daidaito na iya rage faruwar girgiza da hayaniya mara so a cikin kayan aikin injin CNC.

Kammalawa

Amfani da tushen granite don kayan aikin injin CNC kyakkyawan zaɓi ne don kwanciyar hankali da daidaito. Duk da haka, girgiza da hayaniya na iya faruwa yayin aikin injin. Ta hanyar bin dabarun da aka ambata a sama, zaku iya rage girgiza da hayaniya yadda ya kamata. Shigarwa mai kyau, tabarmar keɓewa, damping, da kayan aiki masu daidaito duk hanyoyi ne masu inganci don cimma aiki mai santsi da natsuwa na injunan CNC yayin da ake kiyaye matakan daidaito masu yawa.

Lokacin Saƙo: Maris-26-2024