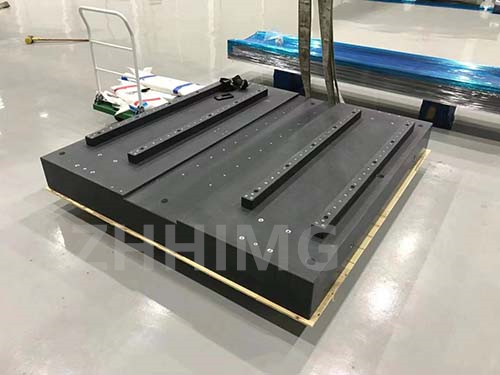

Teburan Granite XY, wanda kuma aka sani da faranti na saman granite daidai, muhimman kayan aiki ne don auna daidai a masana'antu, injiniyanci da kimiyya. Duk da haka, kamar kowane kayan aiki na injiniya, suna iya fuskantar lalacewa, wanda zai iya shafar daidaito da bayyanarsu. Abin farin ciki, akwai hanyoyin gyara bayyanar teburin XY na granite da ya lalace da kuma sake daidaita daidaitonsa, kamar yadda aka tattauna a cikin wannan labarin.

Gyaran Bayyanar Teburin XY na Granite da Ya Lalace

Mataki na farko na gyara yanayin teburin XY na granite da ya lalace shine a tantance girman lalacewar. Wasu nau'ikan lalacewa da aka saba gani sun haɗa da ƙaiƙayi, ƙuraje, guntu, da tabo. Da zarar ka gano nau'in da girman lalacewar, za ka iya ɗaukar matakan da suka dace don gyara ta.

1. Ƙuraje: Idan saman granite yana da ƙananan ƙwanƙwasa, za ku iya gwada amfani da takarda mai laushi ko wani abu na musamman na goge granite don cire ƙanƙancewa. Yi aiki da motsi mai zagaye kuma ku riƙe saman da ruwa don hana takardar yashi ko abin gogewa toshewa.

2. Nicks da Chips: Don zurfafan nicks da chips, za ku buƙaci amfani da sinadarin epoxy resin da aka yi musamman don gyaran granite. Wannan sinadarin yana taimakawa wajen cike yankin da ya lalace, kuma da zarar ya bushe, za ku iya amfani da takarda mai sandpaper don su daidaita shi. Yana da mahimmanci a tabbatar da cewa epoxy ɗin ya bushe yadda ya kamata don guje wa duk wani lalacewa.

3. Tabo: Tabo a saman granite na iya zama babban abin da ke haifar da ido. Sau da yawa ana haifar da waɗannan tabo ta hanyar acid ko wasu sinadarai masu lalata. Idan kun haɗu da tabo, za ku iya amfani da na'urar cire tabo ta granite don cire tabo ta hanyar bin umarnin masana'anta.

Sake daidaita daidaiton Teburin XY na Granite

Da zarar ka gama gyaran yanayin teburin XY na granite, za ka shirya don sake daidaita daidaitonsa. Tsarin daidaitawa yana da mahimmanci domin yana tabbatar da cewa teburin yana ci gaba da bayar da ma'auni daidai gwargwado.

Ga wasu nasihu don taimaka muku sake daidaita teburin XY na granite ɗinku:

1. Daidaitawa: Daidaitawa yana da mahimmanci ga teburin XY na granite, kuma ana iya cimma hakan ta hanyar amfani da kayan aikin daidaita daidaito. Kuna iya amfani da matakin ruhi ko matakin dijital don tabbatar da aikin aiki mai kyau.

2. Tsafta: Tsaftace saman dutse yana da matuƙar muhimmanci, domin duk wani ƙura ko datti na iya shafar daidaiton ma'aunin. Don tsaftace saman, za ku iya amfani da mai tsaftace shi da barasa, kuma da zarar ya bushe, za ku iya amfani da na'urar hura iska don cire duk wani ƙura.

3. Kayan Aikin Daidaita Daidaito: Za ku buƙaci wasu kayan aikin daidaita daidaito don tabbatar da cewa teburin XY na granite ɗinku daidai ne. Waɗannan kayan aikin galibi sun haɗa da ma'aunin tsayi, alamar bugun kira, da kuma prism na farantin saman. Da waɗannan kayan aikin, zaku iya duba cewa teburinku daidai ne, lebur, layi ɗaya, kuma a tsaye.

4. Duba Daidaita ...

Kammalawa

Teburan Granite XY kayan aiki ne masu mahimmanci, kuma daidaitonsu yana da matuƙar muhimmanci ga masana'antu da yawa. Tare da waɗannan muhimman shawarwari kan gyara kamanni da sake daidaita daidaiton teburin granite XY, za ku iya tabbatar da cewa yana ci gaba da samar da ma'auni masu inganci da inganci yayin da yake da kyau. Ku tuna cewa kulawa mai kyau da kuma duba akai-akai suna da mahimmanci don kiyaye teburin granite XY ɗinku cikin kyakkyawan yanayi.

Lokacin Saƙo: Nuwamba-08-2023