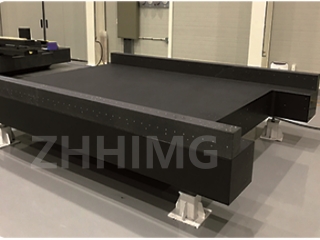

Ana amfani da dutse mai kyau sosai a masana'antu daban-daban kamar injiniyan injiniya, ilimin tsarin ƙasa, da masana'antar gani. An san wannan kayan da kyau saboda kwanciyar hankali, juriya, da daidaito. Duk da haka, bayan lokaci, dutse mai kyau zai iya lalacewa saboda lalacewa da tsagewa, tasirin haɗari, ko fallasa shi ga yanayin zafi mai tsanani. Wannan na iya lalata daidaitonsa kuma ya shafi bayyanarsa.

Idan kuna fuskantar wannan matsala, kada ku damu. A cikin wannan labarin, za mu jagorance ku ta hanyar matakan gyara yanayin granite da ya lalace, da kuma sake daidaita daidaitonsa. Yana da mahimmanci a lura cewa waɗannan matakan suna buƙatar ƙwararren masani tare da kayan aiki da kayan aiki da suka dace.

Gyaran bayyanar Granite mai kyau da ya lalace:

Mataki na 1: Tsaftace Fuskar: Mataki na farko wajen gyara kamannin granite mai kyau shine a tsaftace saman. Yi amfani da kyalle mai laushi da kuma mai tsaftace mara gogewa don cire duk wani datti, ƙura, ko tarkace. Idan saman yana da mai, yi amfani da mai a goge sannan a wanke da ruwa.

Mataki na 2: Duba saman: Duba saman don gano girman da nau'in lalacewar. Wasu nau'ikan lalacewa ana iya gyara su da gogewa mai sauƙi, yayin da wasu kuma suna buƙatar ƙarin dabarun ci gaba.

Mataki na 3: Goge Fuskar: Ana iya goge ƙananan ƙashi ta amfani da sinadarin gogewa da kuma zane mai laushi. Tabbatar an yi amfani da wani sinadari wanda ya dace da saman granite daidai. Ya kamata a shafa sinadarin gogewa a cikin motsi mai zagaye sannan a goge shi da zane mai tsabta.

Don ƙarin gogewa, ana iya amfani da kushin goge lu'u-lu'u. Ya kamata a haɗa kushin ɗin da wani mai gogewa mai saurin canzawa sannan a yi amfani da shi a hankali don guje wa lalata saman. Ya kamata a motsa kushin a cikin motsi mai zagaye, ta amfani da ruwa a matsayin mai shafawa.

Mataki na 4: Cika Fashewa da Ƙwayoyin Cuku: Idan akwai tsagewa ko ƙuraje a saman, ya kamata a cika su da resin epoxy. Ya kamata a haɗa resin ɗin bisa ga umarnin masana'anta sannan a shafa shi a yankin da ya lalace. Bayan resin ya yi laushi, ana iya rage shi zuwa matakin saman da ke kewaye.

Sake daidaita daidaiton dutse mai daidaici:

Mataki na 1: Duba Daidaito: Kafin a sake daidaita daidaiton dutse, yana da mahimmanci a duba daidaitonsa na yanzu. Ana iya yin hakan ta amfani da kayan aiki na daidaitacce kamar na'urar aunawa ta laser ko tubalan ma'auni.

Mataki na 2: Gano Matsalar: Idan aka gano cewa an kashe daidaiton, mataki na gaba shine a gano matsalar. Wannan na iya haɗawa da duba saman don ganin ko akwai lalacewa, duba daidaiton na'urar, ko duba daidaiton kayan aikin aunawa.

Mataki na 3: Daidaita Fuskar: Idan an ga saman granite ɗin bai daidaita ba, ana iya daidaita shi ta amfani da hanyar da aka sani da lapping. Lapping ya haɗa da goge saman granite ɗin da ɗan gogewa don cire manyan tabo da kuma ƙirƙirar saman da ya yi faɗi.

Mataki na 4: Duba Daidaito: Idan an gano cewa matsalar ta shafi daidaiton injin, ya kamata a daidaita ta don tabbatar da cewa tana daidai da saman granite ɗin daidaito. Ana iya yin hakan ta amfani da shims na daidaito ko sukurori na daidaitawa.

Mataki na 5: Sake Daidaita Kayan Aiki: Da zarar an gyara madaidaicin dutse kuma an yi daidai, yana da mahimmanci a sake daidaita kayan aikin aunawa da aka yi amfani da su. Wannan na iya haɗawa da daidaita sifili, daidaita sikelin, ko maye gurbin kayan da suka lalace.

A ƙarshe, granite mai daidaito abu ne mai mahimmanci wanda ke buƙatar kulawa sosai don tabbatar da daidaitonsa da dorewarsa. Ta hanyar bin matakan da aka bayyana a cikin wannan labarin, zaku iya gyara bayyanar granite mai daidaito da ya lalace kuma ku sake daidaita daidaitonsa don tabbatar da cewa ya kasance kayan aiki mai aminci a masana'antar ku.

Lokacin Saƙo: Oktoba-09-2023