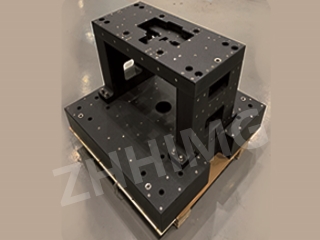

Haɗakar dutse muhimmin abu ne a cikin tsarin kera semiconductor. Yawanci ana amfani da haɗawar a matsayin kayan tushe don gina kayan aikin da aka yi amfani da su wajen samar da semiconductor. Wannan ya faru ne saboda fa'idodi da kaddarorin granite, wanda hakan ya sa ya zama kayan da ya dace da wannan aikace-aikacen.

Ana fifita Granite a masana'antar semiconductor saboda tsananin taurinsa, kwanciyar hankali na zafi, kyakkyawan kwanciyar hankali, da ƙarancin faɗaɗa zafi. Waɗannan kaddarorin suna sanya Granite Haɗawa ya zama kayan aiki mai kyau don aikace-aikacen daidaito waɗanda ke buƙatar babban matakin daidaito, kamar kayan aikin sarrafa wafer na semiconductor.

A cikin tsarin kera semiconductor, amfani da haɗa granite yana tabbatar da daidaito da kuma sanya kayan aiki daban-daban, kamar su wafers, ɗakunan injinan iska, da kayan aikin sarrafawa. Wannan yana da mahimmanci don cimma matakin daidaito da ake buƙata a cikin ƙera semiconductor.

Wani muhimmin fa'idar haɗa duwatsun dutse shine ikonsa na kiyaye siffarsa da girmansa a wurare daban-daban na yanayin zafi. Wannan yana da matuƙar muhimmanci a masana'antar semiconductor, inda ake amfani da yanayin zafi mai yawa a matakai daban-daban na ƙera na'urori.

Bugu da ƙari, haɗakar granite yana ba da kyakkyawan juriya ga lalacewa da tsagewa, wanda hakan ya sa ya zama abu mai ɗorewa kuma mai ɗorewa ga kayan aikin.

A ƙarshe, amfani da haɗakar granite a cikin tsarin kera semiconductor yana da mahimmanci don tabbatar da samar da ingantattun semiconductors. Abubuwan da ke tattare da shi na musamman, kamar ƙarfin tauri, kwanciyar hankali na zafi, da kwanciyar hankali na girma, sun sa ya zama zaɓi mafi kyau don aikace-aikacen daidai. Bugu da ƙari, juriya da juriya ga lalacewa da tsagewa suna tabbatar da cewa kayan aikin da aka yi daga haɗakar granite za su daɗe na dogon lokaci, wanda ke rage farashin kulawa. Saboda haka, masana'antun ya kamata su ci gaba da amfani da wannan kayan don tabbatar da mafi girman daidaito da aminci a cikin tsarin kera semiconductor ɗin su.

Lokacin Saƙo: Disamba-06-2023