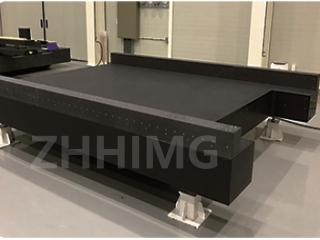

Ana amfani da sansanonin dutse a cikin kayan aikin semiconductor saboda kyakkyawan kwanciyar hankali, tauri, da kuma halayen damshi. Waɗannan sansanonin suna taka muhimmiyar rawa wajen kiyaye daidaito da daidaiton kayan aikin, wanda a ƙarshe ke ba da gudummawa ga ingancin samfuran semiconductor. Saboda haka, yana da mahimmanci a tabbatar da cewa an kula da waɗannan sansanonin sosai kuma sun cika buƙatun da ake buƙata.

Ga wasu daga cikin buƙatun kulawa da kula da sansanonin granite a cikin kayan aikin semiconductor:

1. Tsaftacewa Kullum: Ya kamata a riƙa tsaftace tushen granite akai-akai don hana taruwar ƙura, tarkace, da sauran gurɓatattun abubuwa. Waɗannan abubuwa na iya shafar daidaiton kayan aiki da kuma haifar da lalacewa ga saman granite ɗin. Ya kamata a yi tsaftacewa ta amfani da goga mai laushi ko zane mai microfiber da kuma maganin sabulu mai laushi. Ya kamata a guji sinadarai masu ƙarfi ko masu tsabtace goge-goge, domin suna iya haifar da lalacewa ga saman granite ɗin.

2. Man shafawa: Tushen dutse yana buƙatar man shafawa mai kyau don hana lalacewa da tsagewa da kuma tabbatar da motsi mai santsi na kayan aiki. Ya kamata a yi amfani da man shafawa mai dacewa, kamar man shafawa mai inganci na silicone. Ya kamata a shafa man shafawa kaɗan kaɗan kuma a rarraba shi daidai a saman. Ya kamata a goge man shafawa mai yawa don hana taruwa.

3. Kula da Zafin Jiki: Tushen dutse suna da saurin kamuwa da canje-canje a yanayin zafi, wanda zai iya haifar da faɗaɗa ko matsewar zafi. Ya kamata a ajiye kayan aikin a cikin yanayin da zafin jiki ke sarrafawa, kuma duk wani canji a yanayin zafi ya kamata ya kasance a hankali. Canjin zafin jiki kwatsam na iya haifar da damuwa a saman dutse, wanda ke haifar da tsagewa ko wasu lalacewa.

4. Daidaitawa: Dole ne a daidaita tushen granite don tabbatar da daidaiton rarraba nauyi a saman. Rashin daidaiton rarraba nauyi na iya haifar da damuwa a saman, wanda ke haifar da lalacewa akan lokaci. Ya kamata a yi amfani da alamar matakin don duba matakin tushe akai-akai da kuma daidaita shi kamar yadda ake buƙata.

5. Dubawa: Duba tushen dutse akai-akai yana da mahimmanci don gano duk wata alama ta lalacewa, lalacewa, ko lahani. Duk wani alamu na daban ko na rashin daidaituwa ya kamata a magance shi nan da nan don hana ƙarin lalacewa ko lalacewar kayan aikin.

A ƙarshe, kula da kuma kula da tushen granite a cikin kayan aikin semiconductor yana da matuƙar muhimmanci don tabbatar da daidaito, daidaito, da ingancin kayan aiki da kayayyakin. Tsaftacewa akai-akai, shafa mai, kula da zafin jiki, daidaita matakin, da dubawa wasu daga cikin muhimman buƙatun da ake buƙatar a bi don kiyaye tushen granite a cikin yanayi mafi kyau. Ta hanyar bin waɗannan buƙatu, kamfanonin semiconductor za su iya tabbatar da dorewa da amincin kayan aikinsu da kayayyakinsu, wanda a ƙarshe ke ba da gudummawa ga nasararsu da ci gaban su a masana'antar.

Lokacin Saƙo: Maris-25-2024