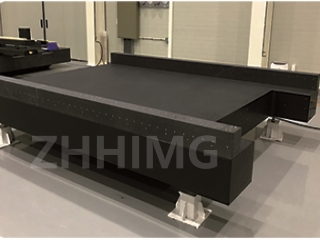

Granite madaidaicin dandamali, tare da babban tsayin su, ƙarancin haɓaka haɓakawa, kyakkyawan aikin damping da kaddarorin anti-magnetic na halitta, suna da ƙimar aikace-aikacen da ba za a iya maye gurbinsu ba a cikin manyan masana'antu da filayen binciken kimiyya inda ake buƙatar daidaito da kwanciyar hankali. Waɗannan su ne ainihin yanayin aikace-aikacen sa da fa'idodin fasaha:

I. Field na Ultra-daidaitaccen kayan aiki

Semiconductor masana'antu kayan aiki

Yanayin aikace-aikace: Lithography inji workpiece tebur, wafer dicing inji tushe, marufi kayan sakawa dandali.

Ƙimar fasaha:

Matsakaicin haɓakar haɓakar thermal na granite shine kawai (0.5-1.0) × 10⁻⁶/℃, wanda zai iya tsayayya da canjin zafin jiki yayin bayyanar nanoscale na injin lithography (kuskuren ƙaura <0.1nm a cikin yanayin ± 0.1℃).

Tsarin micro-pore na ciki yana samar da damping na halitta (damping rabo 0.05 zuwa 0.1), yana hana rawar jiki (amplitude <2μm) yayin yankan saurin sauri ta hanyar injin dicing da kuma tabbatar da cewa ƙarancin ƙarancin Ra na yankan wafer bai wuce 1μm ba.

2. Injunan Niƙa Madaidaici da Injunan Ma'auni (CMM)

Shari'ar aikace-aikacen:

Tushen na'ura mai daidaitawa guda uku yana ɗaukar tsarin granite mai mahimmanci, tare da shimfidar ± 0.5μm/m. Haɗe tare da layin dogo na jagorar iska, yana samun daidaiton motsi na matakin nano (maimaita daidaiton matsayi ± 0.1μm).

The worktable na Tantancewar nika inji rungumi dabi'ar wani hadadden tsari na granite da azurfa karfe. Lokacin niƙa gilashin K9, ƙawancen saman bai kai λ/20 (λ= 632.8nm), saduwa da buƙatun sarrafawa mai laushi na ruwan tabarau na Laser.

Ii. Filin Optics da Photonics

Na'urar hangen nesa ta taurari da tsarin laser

Aikace-aikace na yau da kullun:

Dandali na goyan baya na yanayin hangen nesa na babban na'urar hangen nesa na rediyo yana ɗaukar tsarin saƙar zuma mai ƙanƙara, wanda yake da haske a cikin nauyin kai (yawanci 2.7g/cm³) kuma yana da juriya mai ƙarfi na iska (nakasar <50μm ƙarƙashin iskar 10-mataki).

Dandali na gani na interferometer Laser yana amfani da granite micro-porous. An daidaita mai nuni ta hanyar tallan injin, tare da kuskuren lebur na ƙasa da 5nm, yana tabbatar da daidaiton ƙwararrun gwaje-gwajen gani na gani kamar gano kalaman nauyi.

2. Daidaitaccen kayan aikin gani na gani

Fa'idodin fasaha:

Matsakaicin ƙarfin maganadisu da ƙarfin wutar lantarki na dandamalin granite suna kusa da sifili, suna guje wa tasirin kutsewar lantarki akan matakan daidaitaccen tsari irin su ion beam polishing (IBF) da polishing magnetorheological (MRF). Daidaiton siffar saman ƙimar PV na ruwan tabarau da aka sarrafa na iya kaiwa λ/100.

Iii. Binciken Jirgin Sama da Madaidaici

Dandalin duba bangaren jirgin sama

Yanayin aikace-aikacen: Duban nau'i-nau'i uku na igiyoyin jirgin sama, auna siffa da jurewar matsayi na abubuwan haɗin gine-ginen aluminium na jirgin sama.

Mahimmin aiki:

Ana kula da saman dandalin granite ta hanyar lalatawar electrolytic don samar da tsari mai kyau (tare da rashin ƙarfi na Ra 0.4-0.8μm), wanda ya dace da bincike mai mahimmanci mai mahimmanci, kuma kuskuren gano bayanin martaba bai wuce 5μm ba.

Zai iya jure wa nauyin nauyin 200kg na kayan aikin jirgin sama, kuma canjin kwanciyar hankali bayan amfani da dogon lokaci bai wuce 2μm / m ba, yana saduwa da daidaitattun bukatun kulawa na Grade 10 a cikin masana'antar sararin samaniya.

2. Daidaita abubuwan kewayawa inertial

Bukatun fasaha: Tsayayyen daidaitawa na na'urori marasa amfani kamar gyroscopes da accelerometers suna buƙatar dandamalin tunani mai tsayi.

Magani: An haɗu da dandalin granite tare da tsarin keɓewar rawar jiki mai aiki (mitar yanayi <1Hz), samun daidaitaccen daidaituwa na daidaiton sifili na kwanciyar hankali na abubuwan inertial <0.01 ° / h a cikin yanayi tare da haɓakar girgiza <1 × 10⁻⁻g.

Iv. Nanotechnology da Biomedicine

Scanning microscope (SPM) dandamali

Ayyukan Core: A matsayin tushen tushen microscopy na ƙarfin atomic (AFM) da kuma duban microscopy (STM), yana buƙatar ware shi daga girgizar muhalli da raɗaɗin zafi.

Alamomin aiki:

Dandalin granite, a hade tare da kafafu na keɓancewar pneumatic, na iya rage yawan watsawar girgizar da ke waje (1-100Hz) zuwa ƙasa da 5%, cimma hoton matakin atomic na AFM a cikin yanayin yanayi (ƙuduri <0.1nm).

A zafin jiki ji na ƙwarai ne kasa da 0.05μm / ℃, wanda ya gana da bukatun ga nanoscale lura da nazarin halittu samfurori a cikin wani m zazzabi (37 ℃ ± 0.1 ℃) yanayi.

2. Biochip marufi kayan aiki

Shari'ar aikace-aikacen: Babban madaidaicin madaidaicin dandamali don guntuwar jerin DNA yana ɗaukar ginshiƙan jagororin jagororin iska, tare da daidaiton matsayi na ± 0.5μm, yana tabbatar da haɗin haɗin ƙananan microfluidic tsakanin tashar microfluidic da lantarki mai ganowa.

V. Yanayin aikace-aikacen da ke tasowa

Tushen kayan aikin ƙididdigewa

Kalubalen fasaha: Yin magudin qubit yana buƙatar ƙananan yanayin zafi (matakin mK) da kuma yanayin injina mai ƙarfi.

Magani: Ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan haɓakar haɓakar granite (yawan haɓaka <1ppm daga -200 ℃ zuwa zafin daki) na iya dacewa da halayen ƙanƙancewa na matsananciyar ƙarancin zafin jiki mai ƙarfi, yana tabbatar da daidaiton daidaituwa yayin marufi na kwakwalwan kwamfuta.

2. Electron Beam Lithography (EBL) tsarin

Maɓalli na aiki: Kayan rufin dandali na granite (resistivity> 10¹³Ω · m) yana hana watsewar katako na lantarki. Haɗe tare da ƙwanƙolin sandal ɗin lantarki, yana samun babban madaidaicin ƙirar lithography rubutu tare da faɗin layin nanoscale (<10nm).

Takaitawa

Aikace-aikacen dandali madaidaicin granite ya haɓaka daga injunan daidaitaccen kayan gargajiya zuwa manyan filayen kamar nanotechnology, kididdigar kimiyyar lissafi, da biomedicine. Babban gasa ya ta'allaka ne a cikin zurfafa haɗin kai na kayan abu da buƙatun injiniya. A nan gaba, tare da haɗakar da fasahar ƙarfafa haɗin gwiwa (kamar graphene-granite nanocomposites) da fasaha na fasaha mai hankali, dandamali na granite zai karya ta cikin kwatancen daidaiton matakin atomic, cikakken yanayin yanayin kwanciyar hankali, da haɗin kai da yawa, zama ainihin mahimman abubuwan da ke tallafawa masana'antar masana'anta na gaba.

Lokacin aikawa: Mayu-28-2025