Ga masana'antun da masana kimiyyar ƙasa a faɗin Arewacin Amurka, tun daga tsakiyar masana'antu na Amurka har zuwa ƙa'idodin da ake buƙata na masu samar da farantin saman dutse na Kanada, farantin saman dutse shine ginshiƙin auna girma. Wannan kayan aiki na asali, ko yana aiki azaman mai sauƙi ko kuma an haɗa shi azaman muhimmin sashi a cikin injunan zamani kamar farantin saman dutse na CNC, yana wakiltar babban jari a cikin kula da inganci. Duk da haka, tabbatar da wannan jarin yana buƙatar fahimtar abubuwan da ke haifar da farashi, buƙatun kulawa, da kuma tabbatar da daidaiton daidaito.

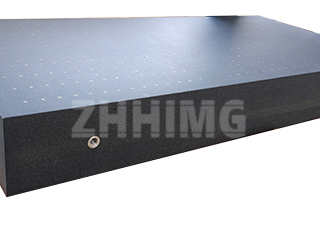

Tambayar farko, "Nawa ne farashin farantin saman granite?", tana buɗe ƙofar zuwa ga wani tsari mai rikitarwa na ƙima. Farashin farantin saman ba wai kawai farashin kayan abu bane; yana nuna ingancin dutsen (yawa, porosity, da kwanciyar hankali), daidaiton tsarin lapping, da kuma tsaurin tsarin takardar shaida. Granite mai rahusa, mai ƙarancin yawa, wanda galibi ana gano shi ta hanyar launinsa mai sauƙi, na iya adana farashin farantin saman granite na gaba, amma babu makawa yana haifar da ƙarin kuɗaɗen dogon lokaci saboda saurin lalacewa, mafi yawan kamuwa da rashin kwanciyar hankali na zafi, da kuma sake daidaita shi akai-akai. Granite baƙi mai tsada, kamar kayan mallakar ZHHIMG® da ake amfani da shi tare da yawa kusa da 3100 kg/m³, yana tabbatar da kwanciyar hankali mafi kyau da ƙarancin kulawa akai-akai, yana mai da shi zaɓi mafi araha a tsawon rayuwar samfurin.

Wannan tsawon rai yana da alaƙa kai tsaye da muhimman ayyukan kula da farantin saman granite. Farantin granite, duk da cewa yana da ƙarfi, yana da sauƙin kamuwa da manyan masu adawa guda biyu: lalacewar abrasive da girgizar zafi. Tsarin kula da farantin saman granite mai cikakken tsari dole ne ya magance duka biyun da kyau.

Wani muhimmin sashi na wannan tsari shine tsaftace farantin saman granite. Tsarin tsaftace saman farantin granite mai kyau ba wai kawai game da cire datti da ake iya gani ba ne; yana game da kawar da ƙananan ƙwayoyin cuta masu ɓarna - kamar niƙa ƙura ko swarf na ƙarfe - waɗanda, idan aka makale tsakanin kayan aikin da granite, suna aiki kamar takarda mai yashi, suna lalata madaidaicin da aka tabbatar. Kada a taɓa amfani da sabulun wanki mai ƙarfi ko masu tsabtace acidic, waɗanda za su iya barin ragowar ko kuma su goge saman dutsen. Madadin haka, dole ne a yi amfani da maganin tsaftace farantin saman granite mai tsaka-tsaki, wanda aka haɗa shi da zane na musamman, wanda ba shi da lint, kowace rana don kiyaye yanayin tsabta na matakin tunani. Wannan matakin yau da kullun ba za a iya yin shawarwari ba don kiyaye daidaito, musamman ga faranti da ke aiki a Mataki na 00 ko juriyar dakin gwaje-gwaje.

Duk da haka, ko da tsaftacewa da kulawa mafi tsauri ba za su iya hana tasirin amfani da canje-canjen muhalli a hankali ba. Wannan yana kawo mu ga buƙatar farantin saman dutse mai daidaito. Kalmar "daidaitawa" galibi ana amfani da ita ba daidai ba; dole ne ta nuna tabbacin da za a iya bi na faɗin faɗin farantin, faɗin yankin, da kuma maimaituwa. Masana'antu masu inganci, gami da waɗanda masu samar da farantin saman dutse na Kanada ke yi wa hidima, sun dogara ne da takaddun shaida na aunawa da za a iya bi ta hanyar dakunan gwaje-gwaje masu izini waɗanda ke amfani da hanyoyin laser da matakan lantarki.

Jajircewar ZHHIMG® ga daidaito ta tabbatar da cewa kowace faranti da ta bar wurin sarrafa yanayi mai girman murabba'in mita 10,000—tsarin da aka gina da siminti mai girgiza da ramukan keɓewa na girgiza—an tabbatar da shi sosai. Wannan sadaukarwar tana da mahimmanci musamman lokacin da aka yi amfani da farantin a matsayin tushen farantin saman granite CNC. A cikin wannan aikace-aikacen, farantin yana aiki a matsayin tushen tsarin jagororin layi da injinan injin. Duk wani kuskuren geometric a cikin granite ana fassara shi nan take zuwa kurakurai a cikin sarrafa motsi na CNC, wanda ke shafar daidaiton sassan injin na ƙarshe. Saboda haka, tazara tsakanin daidaitawa don aikace-aikacen farantin saman granite CNC ya kamata ya zama mai yawan gaske kuma mai tsauri fiye da na farantin dubawa na yau da kullun.

Bayan lanƙwasa da ingancin kayan aiki, masu amfani dole ne su yi la'akari da ƙirar tsarin. Ingantaccen tsarin farantin saman tubalin dutse—gami da ƙira da sanya kayan ɗagawa, wuraren tallafi, da kuma rabon kauri-zuwa-tsayi gaba ɗaya—yana da mahimmanci don hana karkacewa a ƙarƙashin kaya. Wannan daidaiton tsarin shine babban abin da ke haifar da ainihin farashin farantin saman dutse kuma alama ce ta masana'antun duniya waɗanda suka fahimci cewa daidaito an gina shi daga tushe zuwa sama.

Ta hanyar fifita yawan kayan da suka fi yawa, aiwatar da kula da farantin saman granite da tsaftace tsarin farantin saman granite, da kuma sadaukar da kai ga ayyukan farantin saman granite da za a iya ganowa akai-akai, masu amfani suna tabbatar da cewa tushen metrology ɗinsu ya kasance wuri mai ban sha'awa, yana isar da daidaiton matakin nanometer daidai gwargwado ba tare da la'akari da inda suka samo farantinsu ba - ko daga mai siyarwa na gida ko kuma shugaban ƙasa kamar ZHHIMG®.

Lokacin Saƙo: Nuwamba-25-2025