Gadon injin yana aiki a matsayin babban ɓangaren tushen kowace kayan aikin injiniya, kuma tsarin haɗa shi muhimmin mataki ne wanda ke nuna taurin tsarin, daidaiton geometric, da kwanciyar hankali na dogon lokaci. Ba kamar haɗakar da aka yi da ƙulli ba, gina gadon injin daidaitacce ƙalubale ne na injiniyan tsarin matakai da yawa. Kowane mataki - daga nuni na farko zuwa daidaitawar aiki na ƙarshe - yana buƙatar iko mai ƙarfi na masu canji da yawa don tabbatar da cewa gadon yana da ingantaccen aiki a ƙarƙashin nauyin aiki mai rikitarwa.

Tsarin Aiki: Nazari na Farko da Daidaita Daidaito

Tsarin haɗawa yana farawa da kafa cikakken tsarin tunani. Yawanci ana samun wannan ta amfani da farantin saman granite mai inganci ko na'urar bin diddigin laser a matsayin ma'aunin duniya. Da farko ana daidaita tushen gadon injin ta amfani da madaidaitan matakan tallafi (toshe-toshe). Ana amfani da kayan aikin aunawa na musamman, kamar matakan lantarki, don daidaita waɗannan tallafi har sai an rage kuskuren daidaitawa tsakanin saman jagorar gado da saman tunani.

Ga manyan gadaje, ana amfani da dabarun daidaita matakai: ana gyara wuraren tallafi na tsakiya da farko, kuma daidaita yana ci gaba zuwa ƙarshen. Ci gaba da sa ido kan madaidaiciyar hanyar jagora ta amfani da alamar dial yana da mahimmanci don hana faɗuwa a tsakiya ko karkacewa a gefuna saboda nauyin kayan. Haka kuma ana ba da hankali ga kayan haɗin tallafi; sau da yawa ana zaɓar ƙarfe mai siminti saboda irin wannan ma'aunin faɗaɗa zafi zuwa ga gadon injin, yayin da ake amfani da madaidaitan kushin don mafi kyawun halayen damshi a aikace-aikacen da ke da saurin girgiza. Fim ɗin siriri na man shafawa na musamman da ke hana kamawa a saman hulɗa yana rage tsangwama na gogayya kuma yana hana zamewa a cikin lokacin daidaitawa na dogon lokaci.

Haɗin kai na Daidaito: Haɗa Tsarin Jagora

Tsarin hanyar jagora shine babban ɓangaren da ke da alhakin motsi na layi, kuma daidaiton haɗawarsa yana daidai da ingancin injin kayan aiki. Bayan an fara gyara shi da fil ɗin gano wuri, ana ɗaure hanyar jagora, kuma ana amfani da ƙarfin kafin tashin hankali sosai ta amfani da faranti na latsawa. Tsarin kafin tashin hankali dole ne ya bi ƙa'idar "daidaitacce kuma mai ci gaba": ana ƙara matse kusoshi kaɗan daga tsakiyar hanyar jagora zuwa waje, ana amfani da ƙarfin juyi kaɗan kawai a kowane zagaye har sai an cika ƙa'idodin ƙira. Wannan tsari mai tsauri yana hana yawan damuwa na gida wanda zai iya haifar da sunkuyar hanyar jagora.

Babban ƙalubale shine daidaita wurin da ke gudana tsakanin tubalan zamiya da hanyar jagora. Ana cimma wannan ta hanyar haɗa ma'aunin ji da hanyar auna alamar dial. Ta hanyar saka ma'aunin ji mai kauri daban-daban da kuma auna wurin da aka canza wurin zamiya tare da alamar dial, ana samar da lanƙwasa na sharewa da ƙaura. Wannan bayanin yana jagorantar ƙaramin daidaitawa na fil ko tubalan wedge a gefen zamiya, yana tabbatar da rarrabawar daidaito. Don gadaje masu daidaito sosai, ana iya amfani da fim ɗin man shafawa na nano a saman hanyar jagora don rage yawan gogayya da haɓaka santsi na motsi.

Haɗin kai mai ƙarfi: Sandal Headstock zuwa gado

Haɗin da ke tsakanin sandar kai, zuciyar fitar da wutar lantarki, da kuma gadon injin yana buƙatar daidaito mai kyau na watsa kaya mai ƙarfi da keɓewar girgiza. Tsaftar saman haɗuwa yana da matuƙar muhimmanci; dole ne a goge wuraren hulɗa da kyau da wani maganin tsaftacewa na musamman don cire duk wani gurɓatawa, sannan a shafa siririn man silicone na musamman don ƙara taurin hulɗa.

Tsarin matse ƙulli yana da matuƙar muhimmanci. Ana amfani da tsari mai daidaito, wanda yawanci "ke faɗaɗawa daga tsakiya," ana fara matse ƙulli a yankin tsakiya, tare da haskawa daga waje. Dole ne a yi la'akari da lokacin sakin damuwa bayan kowane zagaye mai matsewa. Ga masu ɗaurewa masu mahimmanci, ana amfani da na'urar gano ƙulli mai ɗaukar hoto ta ultrasonic don sa ido kan ƙarfin axial a ainihin lokaci, yana tabbatar da rarraba damuwa iri ɗaya a duk ƙulli da kuma hana sassautawa ta gida wanda zai iya haifar da girgizar da ba a so.

Bayan haɗawa, ana yin nazarin yanayin aiki. Mai kunna sauti yana haifar da girgiza a takamaiman mitoci akan kan kai, kuma masu auna saurin gudu suna tattara siginar amsawa a fadin gadon injin. Wannan yana tabbatar da cewa mitoci masu amsawa na tushe sun rabu da isasshen kewayon mitoci na aiki na tsarin. Idan an gano haɗarin resonance, ragewa ya haɗa da shigar da damping shims a mahaɗin ko kuma ƙara ƙarfin bolt don inganta hanyar watsa girgiza.

Tabbatarwa ta Ƙarshe da Diyya na Daidaiton Geometric

Da zarar an haɗa shi, dole ne a yi cikakken bincike na geometric na ƙarshe. Na'urar auna haske ta laser tana auna madaidaiciyar hanya, ta amfani da haɗa madubai don ƙara girman ƙananan karkacewa a tsawon hanyar jagora. Tsarin matakin lantarki yana zana taswirar saman, yana kafa bayanin martaba na 3D daga wuraren aunawa da yawa. Mai haɗa haske ta atomatik yana duba daidaituwa ta hanyar nazarin canjin wurin haske da aka nuna daga madaidaicin prism.

Duk wani karkacewa da aka gano ba tare da haƙuri ba yana buƙatar diyya mai kyau. Ga kurakuran madaidaiciyar hanya a kan hanyar jagora, ana iya gyara saman maƙallin tallafi ta hanyar goge hannu. Ana amfani da wakilin haɓaka zuwa manyan wuraren, kuma gogayya daga maƙallin da ke motsawa yana bayyana tsarin hulɗa. Ana goge manyan wuraren sosai don a hankali cimma daidaiton ka'idar. Ga manyan gadaje inda gogewa ba ta da amfani, ana iya amfani da fasahar diyya ta hydraulic. An haɗa ƙananan silinda na hydraulic a cikin maƙallan tallafi, suna ba da damar daidaita kauri mara lalacewa ta hanyar daidaita matsin mai, cimma daidaito ba tare da cire kayan zahiri ba.

Saukewa da kuma ɗaukar nauyin aiki

Matakan ƙarshe sun haɗa da yin aiki. A lokacin matakin gyara kurakurai da aka sauke, gadon yana aiki a ƙarƙashin yanayin kwaikwayo yayin da kyamarar zafi ta infrared ke lura da lanƙwasa yanayin zafin kan kai kuma yana nuna wuraren zafi na gida don yuwuwar inganta tashar sanyaya. Na'urori masu auna karfin juyi suna lura da canjin fitowar motar, wanda ke ba da damar daidaita hanyoyin cirewa na tuƙi. Matakin gyara kurakurai da aka ɗora yana ƙara ƙarfin yankewa a hankali, yana lura da rawar jiki na gadon da ingancin ƙarewar saman injin don tabbatar da cewa tsauraran tsarin ya cika ƙa'idodin ƙira a ƙarƙashin matsin lamba na gaske.

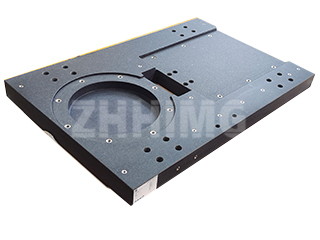

Haɗa kayan gadon injina haɗin kai ne na tsari na matakai da yawa, waɗanda aka sarrafa daidai. Ta hanyar bin ƙa'idodin haɗa kayan aiki, hanyoyin diyya masu ƙarfi, da kuma cikakken tabbatarwa, ZHHIMG yana tabbatar da cewa gadon injin yana kiyaye daidaiton matakin micron a ƙarƙashin nauyi mai rikitarwa, yana samar da tushe mai ƙarfi don aikin kayan aiki na duniya. Yayin da gano kayan aiki masu wayo da fasahar daidaitawa ta kai ke ci gaba da ci gaba, haɗa kayan aikin injina na gaba zai zama mai faɗi da haɓaka kai tsaye, yana tura kera injina zuwa sabbin tsare-tsare na daidaito.

Lokacin Saƙo: Nuwamba-14-2025