;

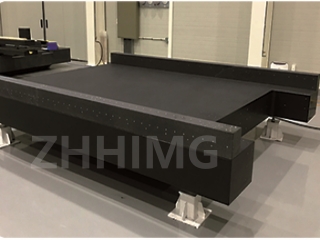

A cikin yanayin sarrafawa mai inganci na injunan alamar laser matakin picosecond, tushe, a matsayin babban ɓangaren tallafi na kayan aiki, zaɓin kayansa kai tsaye yana ƙayyade daidaiton sarrafawa. Granite da ƙarfe simintin ƙarfe abubuwa ne guda biyu gama gari don kera tushe. Wannan labarin zai gudanar da kwatantawa daga fannoni kamar halayen zahiri, ƙa'idar rage daidaito, da bayanan aikace-aikacen aiki, yana samar da tushen kimiyya don haɓaka kayan aiki.

I. Bambance-bambancen Kadarorin Kayan Aiki: Babban Ma'anar Aikin Daidaito

Granite dutse ne na halitta mai kama da dutse mai kama da dutse, wanda aka samar ta hanyar haɗa ma'adanai kamar quartz da feldspar a ciki. Yana da tsari mai yawa da kuma taurin kai mai yawa. Yawansa yawanci yana tsakanin 2.7 da 3.1g/cm³, kuma yawan faɗaɗa zafinsa yana da ƙasa sosai, kusan (4-8) ×10⁻⁶/℃, wanda zai iya tsayayya da tasirin canjin zafin jiki akan daidaiton kayan aiki. Bugu da ƙari, tsarin granite na musamman yana ba shi kyakkyawan aikin damfara, yana ba shi damar shan kuzarin girgiza na waje cikin sauri da rage tsangwama na girgiza akan daidaiton sarrafawa.

Iron ɗin da aka yi da siminti, a matsayin kayan masana'antu na gargajiya, yana da yawa kusan 7.86g/cm³, ƙarfin matsi mai ƙarfi, amma yana da zafi sosai.

Adadin faɗaɗawa (kimanin 12×10⁻⁶/℃) ya ninka na granite sau 1.5-3. Bugu da ƙari, akwai tsarin flake graphite a cikin ƙarfen siminti. A lokacin amfani da shi na dogon lokaci, waɗannan tsarin na iya haifar da yawan damuwa, yana shafar daidaiton kayan kuma daga baya yana haifar da raguwar daidaito.

Ii. Tsarin Rage Daidaito a Injin Matakin Picosecond

Sarrafa laser matakin Picosecond yana da matuƙar buƙata don kwanciyar hankali a muhalli. Duk wani ɗan ƙaramin nakasu na kayan tushe zai ƙaru zuwa sakamakon sarrafawa. Canjin zafin jiki, girgizar da kayan aiki ke haifarwa, gajiya a ƙarƙashin kaya na dogon lokaci, da sauransu, duk manyan abubuwan ne ke haifar da raguwar daidaito.

Idan zafin jiki ya canza, girman dutse yana canzawa kaɗan saboda ƙarancin yawan faɗaɗa zafi. Babban adadin faɗaɗa zafi na ƙarfen siminti zai sa tushen ya fuskanci nakasu wanda yake da wahalar ganowa da ido tsirara. Wannan nakasu zai shafi daidaiton hanyar gani ta laser kai tsaye kuma ya sa matsayin alama ya canza. Dangane da girgiza, babban yanayin danshi na dutse na iya rage girgizar 100Hz cikin daƙiƙa 0.12, yayin da ƙarfen siminti yana buƙatar daƙiƙa 0.9. A ƙarƙashin yanayin girgiza mai yawan mita, daidaiton sarrafawa na kayan aiki tare da tushen ƙarfe siminti ya fi saurin canzawa.

Iii. Kwatanta Bayanan Rage Daidaito

A cewar gwaje-gwajen cibiyoyin ƙwararru, yayin ci gaba da aikin alamar laser picosecond na awanni 8, raguwar daidaiton matsayin XY-axis na kayan aiki tare da tushen granite yana cikin ±0.5μm. Daidaiton rage kayan aikin tushen ƙarfe na simintin ya kai ±3μm, tare da babban bambanci. A cikin yanayin kwaikwayo tare da canjin zafin jiki na 5℃, kuskuren nakasar zafi na kayan aikin tushen granite shine + 0.8μm kawai, yayin da na kayan aikin tushen ƙarfe na simintin yana da girman + 12μm.

Bugu da ƙari, daga mahangar amfani da shi na dogon lokaci, ƙimar fahimtar kuskuren tushe na dutse shine 0.03% kawai, yayin da ƙimar fahimtar kuskuren tushe na ƙarfen simintin ya kai 0.5% saboda matsalolin kwanciyar hankali na tsarin. Waɗannan bayanai sun nuna sarai cewa a ƙarƙashin buƙatun daidaito na sarrafa matakin picosecond, fa'idar kwanciyar hankali na tushen dutse yana da mahimmanci.

Iv. Shawarwari Masu Ingantawa da Aikace-aikace Masu Amfani

Ga kamfanonin da ke bin ingantaccen sarrafa kayan aiki, haɓaka tushen ƙarfen siminti zuwa tushen granite hanya ce mai inganci don haɓaka aikin kayan aiki. A lokacin haɓaka kayan aiki, ya kamata a mai da hankali kan daidaiton sarrafa kayan aikin don tabbatar da cewa faɗin saman ya cika buƙatun ƙira. A lokaci guda, tare da na'urori masu taimako kamar tsarin keɓewar girgizar iska, ana iya ƙara inganta aikin hana girgiza na kayan aikin.

A halin yanzu, a cikin masana'antu kamar kera guntu na semiconductor da sarrafa kayan gani daidai, an yi amfani da injunan alama na laser tare da tushen granite sosai, wanda hakan ke haɓaka yawan amfanin samfura da ingancin samarwa yadda ya kamata. Misali, bayan da wani kamfanin kera kayan gani ya haɓaka kayan aikin tushen ƙarfe na siminti, ƙimar cancantar samfurin ta ƙaru daga kashi 82% zuwa kashi 97%, kuma an ƙara inganta ingancin samarwa sosai.

A ƙarshe, a cikin haɓaka tushe na injunan alamar laser matakin picosecond, granite, tare da ingantaccen kwanciyar hankali na zafi, babban aikin damfara da kuma ikon riƙe daidaito na dogon lokaci, ya zama zaɓi mafi kyau fiye da ƙarfen siminti. Kamfanoni na iya zaɓar kayan tushe bisa ga buƙatun sarrafawa da kasafin kuɗinsu don cimma cikakken haɓaka aikin kayan aiki.

Lokacin Saƙo: Mayu-19-2025