A fagen injunan alamar Laser-matakin picosecond, daidaito shine ainihin ma'anar kimanta aikin kayan aiki. Tushen, a matsayin maɓalli mai mahimmanci don tsarin laser da daidaitattun abubuwan da aka gyara, kayan sa kai tsaye yana shafar kwanciyar hankali na daidaiton aiki. Granite da simintin ƙarfe, azaman kayan tushe guda biyu na yau da kullun, suna da bambance-bambance masu mahimmanci a cikin madaidaicin halayen attenuation yayin sarrafa matakin-matakin picosecond. Wannan labarin zai zurfafa nazarin fa'idar aiki da rashin amfani na biyu don samar da tushen kimiyya don haɓaka kayan aiki. ;

Kaddarorin kayan aiki sun ƙayyade tushen madaidaicin

Granite da gaske dutse ne mai ban tsoro da aka samar ta hanyar tsarin ilimin ƙasa sama da ɗaruruwan miliyoyin shekaru. Tsarin kristal ɗinsa na ciki yana da yawa kuma iri ɗaya, tare da madaidaicin haɓakar faɗaɗa madaidaiciya kamar ƙasan 0.5-8 × 10⁻⁶/℃, kwatankwacin na madaidaicin gami kamar karfe indium. Wannan sifa tana sa canjin girmanta ya kusan zama sakaci lokacin da yanayin yanayi ya canza, yadda ya kamata ya guje wa ɓata hanyar gani da kurakuran injina da ke haifar da haɓakar zafi da raguwa. Bugu da kari, da yawa na granite ya kai 2.6-2.8g/cm³, wanda a zahiri yana da kyakkyawan ƙarfin ɗaukar girgiza. Zai iya hanzarta rage yawan girgizar da aka yi a lokacin sarrafa Laser, yana tabbatar da kwanciyar hankali na tsarin gani da sassa masu motsi. ;

Ana amfani da sansanonin simintin simintin gyare-gyare da yawa saboda kyakkyawan aikin simintin su da fa'idodin farashi. Siffar ginshiƙi na al'ada na simintin simintin launin toka yana ba shi wasu ƙayyadaddun aikin damping, wanda zai iya ɗaukar kusan 30% zuwa 50% na kuzarin girgiza. Koyaya, ƙimar haɓakar haɓakar ƙarfe na simintin ƙarfe kusan 10-12 × 10⁻⁶/℃, wanda shine sau 2-3 na granite. Ƙarƙashin tarin zafi da ake samarwa ta hanyar ci gaba da aiki na dogon lokaci, nakasawa mai girma yana yiwuwa ya faru. A halin yanzu, ana samun damuwa a cikin simintin ƙarfe. Yayin da aka saki damuwa yayin tsarin amfani, yana iya haifar da canje-canje maras canzawa a cikin lebur da madaidaicin tushe. ;

Madaidaicin tsarin attenuation a cikin sarrafa matakin-picosecond

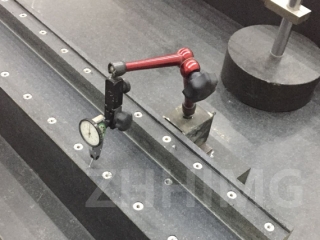

Picosecond Laser sarrafa, tare da matsananci-gajeren bugun jini halaye, na iya cimma kyau aiki a sub-micron matakin ko ma da nanometer matakin, amma kuma ya gabatar da m bukatun ga kwanciyar hankali na kayan aiki. Tushen granite, tare da tsayayyen tsari na ciki, na iya sarrafa amsawar girgiza a matakin ƙananan micron a ƙarƙashin tasirin laser mai girma, yadda ya kamata yana kiyaye daidaiton matsayi na mayar da hankali na laser. Bayanan da aka auna sun nuna cewa na'ura mai alamar Laser tare da tushe mai tushe har yanzu yana kula da karkatar da nisa tsakanin ± 0.5μm bayan ci gaba da sarrafa picosecond na sa'o'i 8. ;

Lokacin da simintin simintin simintin gyare-gyaren da aka fallasa zuwa babban motsi na picosecond Laser, tsarin hatsi na ciki zai fuskanci gajiyar microscopic saboda ci gaba da tasiri, wanda zai haifar da raguwa a cikin rigidity na tushe. Saka idanu bayanai daga wani semiconductor masana'antu masana'antu nuna cewa bayan watanni shida na aiki, da aiki daidaito attenuation kudi na kayan aiki tare da jefa baƙin ƙarfe sansanonin ya kai 12%, yafi bayyana a matsayin karuwa a cikin roughness na line gefuna da kuma fadada na sakawa kurakurai. A halin yanzu, simintin gyare-gyaren yana da ɗan damuwa da zafi na muhalli. Amfani na dogon lokaci yana da haɗari ga tsatsa, yana ƙara haɓaka haɓakar daidaito. ;

Tabbatar da bambance-bambancen aiki a aikace-aikace masu amfani

A cikin fannin sarrafa kayan aikin lantarki na 3C, wani sanannen kamfani ya gudanar da gwajin kwatancen kayan aiki na nau'ikan tushe guda biyu. A cikin gwajin, injunan alamar Laser picosecond guda biyu tare da tsari iri ɗaya an sanye su da granite da simintin ƙarfe don yanke da yiwa gilashin fuskar wayar hannu da faɗin 0.1mm. Bayan sa'o'i 200 na ci gaba da sarrafawa, ƙimar riƙe daidaiton daidaiton kayan aikin granite ya kasance 98.7%, yayin da na simintin ƙarfe na ƙarfe ya kasance kawai 86.3%. Gefen gilashin da na ƙarshe ya sarrafa ya nuna a fili lahani na sawtooth. ;

A cikin masana'antar abubuwan haɗin sararin samaniya, bayanan sa ido na dogon lokaci na wani cibiyar bincike da hankali yana nuna bambance-bambance: Na'urar yin alama ta Laser tare da tushe mai granite yana da ƙimar daidaitaccen ƙimar ƙasa da 3μm a cikin rayuwar sabis na shekaru biyar; Koyaya, bayan shekaru uku, kuskuren sarrafawa na kayan ginin simintin ƙarfe na simintin ƙarfe wanda ya haifar da nakasar tushe ya wuce daidaitattun tsari na ± 10μm, kuma dole ne a aiwatar da daidaitaccen daidaiton injin gabaɗaya. ;

Shawarwari don haɓaka yanke shawara

Idan kamfanoni sun ɗauki ingantaccen aiki mai tsayi da tsayin zagayowar azaman ainihin buƙatun su, musamman a fannoni kamar kwakwalwan kwamfuta na semiconductor da ingantattun kayan aikin gani, sansanonin granite, tare da ingantaccen kwanciyar hankali da juriyar rawar jiki, zaɓin ingantacciyar zaɓi ne. Kodayake farashin siyan sa na farko shine kashi 30% zuwa 50% sama da na simintin ƙarfe, daga mahangar cikakken farashi na rayuwa, raguwar ƙimar daidaitaccen daidaitawa da rage lokacin kayan aiki don kulawa na iya haɓaka fa'idodin gabaɗaya. Don yanayin aikace-aikacen tare da ƙananan buƙatun daidaiton sarrafawa da iyakanceccen kasafin kuɗi, za a iya amfani da sansanonin simintin ƙarfe azaman mafita na tsaka-tsaki a ƙarƙashin jigo na sarrafa yanayin amfani. ;

Ta hanyar kwatanta daidaitattun halaye na granite da simintin ƙarfe a cikin sarrafa matakin-picosecond, ana iya ganin cewa zabar kayan tushe da ya dace shine babban mataki don haɓaka daidaiton aiki da amincin injin alamar Laser. Ya kamata kamfanoni, bisa la'akari da buƙatun fasaha na kansu da la'akarin farashi, yanke shawarar kimiyya akan tsarin haɓaka tushe don samar da ingantaccen tushe na kayan aiki don masana'anta na ƙarshe. ;

Lokacin aikawa: Mayu-22-2025