A fannin masana'antu na zamani da kuma ci gaban bincike na kimiyya, buƙatar sarrafa motsi mai inganci yana ƙaruwa. Tsarin iska mai ƙarfi mai tsauri, a matsayin babban kayan aikin sarrafa motsi mai matuƙar daidaito, ya zama babban taimako ga masana'antu da yawa don cimma nasarori tare da kyakkyawan aikin sa.

Na farko, fasahar asali: tallafin iyo a iska, madaidaicin matsin lamba mai tsauri

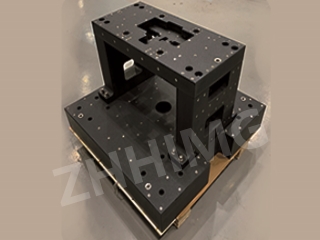

Dandalin iska mai matsakaicin matsin lamba mai daidaito yana amfani da fasahar flotation ta iska mai ci gaba, ta hanyar ƙirƙirar fim ɗin iska mai matsin lamba iri ɗaya da kwanciyar hankali tsakanin dandamalin da tushe, an dakatar da dandamalin. Wannan Layer na fim ɗin iskar gas kamar "matashi mai iska" ne mai sihiri, don haka dandamalin ba shi da hulɗa kai tsaye da tushe yayin motsi, yana rage yawan gogayya, kuma kusan yana kawar da lalacewa da abin da ke haifar da hulɗar injiniya ta gargajiya. A lokaci guda, tsarin tuƙi mai daidaito yana tabbatar da cewa dandamalin zai iya cimma daidaito mai girma da kwanciyar hankali mai tsayi bisa ga hanyar da aka riga aka saita, kuma daidaiton matsayi na iya kaiwa zuwa nanometers, yana samar da tushe mai ƙarfi don ayyukan daidaito daban-daban.

Na biyu, madaidaicin gaske: matsakaicin matakin micron ko ma nanometer

A fannin kera guntu na semiconductor, tsarin lithography yana buƙatar daidaiton matsayi mai kyau. Tare da kyakkyawan ikon sarrafa daidaitonsa, dandamalin iska mai matsin lamba mai tsauri na iya sarrafa kuskuren matsayi na kayan aikin lithography na guntu a cikin tsari na nanometer, canja wurin tsarin da'ira zuwa wafer daidai, taimakawa wajen kera ƙananan guntu masu haɗawa, da haɓaka masana'antar semiconductor don ci gaba da matsawa zuwa matakin tsari mafi girma. A fannin niƙa ruwan tabarau na gani, dandamalin zai iya sarrafa hanyar motsi na kayan aikin niƙa daidai, don haka daidaiton sarrafawa na saman ruwan tabarau zai iya kaiwa matakin micron ko ma ƙaramin micron, kuma ya samar da ruwan tabarau mai inganci da ƙarancin rashin daidaituwa don biyan buƙatun tsauraran kyamarori masu inganci, na'urorin hangen nesa, na'urorin hangen nesa da sauran kayan aikin gani.

Kyakkyawan kwanciyar hankali: tsangwama mai ware, aiki akai-akai

Girgizar waje da canjin zafin jiki su ne manyan "masu laifi" guda biyu da ke shafar daidaiton kayan aiki na daidaitacce. Dandalin iyo na iska mai daidaiton matsin lamba mai tsauri yana da tsarin keɓewar girgiza mai aiki sosai, wanda zai iya toshe tsangwama daga yanayin da ke kewaye, kamar aikin manyan kayan aiki a cikin bitar masana'anta, girgizar zirga-zirga, da sauransu, don tabbatar da cewa dandamalin har yanzu yana iya aiki cikin kwanciyar hankali a cikin yanayi mai rikitarwa. A lokaci guda, dandamalin yana ɗaukar kayan aiki da ƙirar tsari tare da kyakkyawan kwanciyar hankali na zafi, wanda ba shi da la'akari da canjin zafin jiki, kuma har yanzu yana iya kiyaye kwanciyar hankali da motsi mai inganci a cikin yanayin canjin zafin jiki, yana ba da garanti mai inganci don injina da gwaji daidaitacce.

Na huɗu, aikace-aikace iri-iri: wasan daidaito na fili da yawa

A fannin kera jiragen sama, ana amfani da dandamalin iyo na iska mai daidaiton matsin lamba mai tsauri don sarrafa sassan jiragen sama, kamar niƙa ruwan wukake na injin jirgin sama, haƙa sassan tsarin jirgin sama, da sauransu, don tabbatar da daidaiton sarrafa sassan da inganta aiki da amincin jiragen sama. A cikin binciken likitanci, dandamalin yana taimakawa kayan aikin jerin kwayoyin halitta su motsa zane-zanen samfura daidai don cimma ingantaccen karatun bayanan kwayoyin halitta; A cikin micromanipulation na ƙwayoyin halitta, kayan aiki kamar microneedles da micropipettes ana sarrafa su daidai don gudanar da ayyuka masu kyau akan ƙwayoyin halitta daban-daban da kuma haɓaka zurfafa binciken likitanci. Bugu da ƙari, a cikin kera kayan lantarki, kera kayan aiki masu inganci da sauran masana'antu, dandamalin iyo na iska mai matsin lamba mai tsauri shima yana taka muhimmiyar rawa ba tare da maye gurbinsa ba.

Na biyar, ayyuka na musamman: don biyan buƙatun mutum ɗaya

Sanin cewa masana'antu daban-daban da abokan ciniki daban-daban suna da buƙatu daban-daban na dandamalin flotation na iska mai matsin lamba mai tsauri, muna ba da cikakken sabis na musamman. Daga girman da ƙarfin ɗaukar nauyin dandamali zuwa matakin bugun motsi da daidaito, ana iya aiwatar da ƙira da samarwa na musamman bisa ga ainihin yanayin aikace-aikacen da buƙatun aiwatarwa na abokan ciniki. Ƙwararrun ƙungiyar R&D za su yi aiki tare da abokan ciniki don tabbatar da cewa kowane dandamalin float na iska mai matsin lamba mai tsauri zai iya biyan buƙatun abokin ciniki daidai da kuma ƙirƙirar mafi girman ƙima ga abokan ciniki.

Zaɓin dandamalin da ke da matsi mai tsauri na iska mai iyo shine zaɓar mafi kyawun mafita na sarrafa motsi mai matuƙar daidaito, buɗe sabon babi na masana'antu masu inganci da bincike na kimiyya, taimaka muku ficewa a kasuwar gasa, da kuma cimma sau biyu na fasaha da masana'antu.

Lokacin Saƙo: Afrilu-10-2025