A fannin kera daidaici, gwajin binciken kimiyya da sauran buƙatun daidaito na filin, daidaitaccen matsi mai tsauri na iska mai iyo yana taka muhimmiyar rawa. Zaɓin tushen dandamali, kamar shimfida ginshiƙi don ginin, yana da alaƙa kai tsaye da aikin dandamalin. Tushen daidaiton dutse da tushen simintin ma'adinai a matsayin zaɓuɓɓuka biyu masu shahara, kowannensu yana da nasa fa'idodi, ga cikakken kwatancen a gare ku.

Kwanciyar Hankali: Bambanci tsakanin lu'ulu'u na halitta da kuma haɗin wucin gadi

Tushen daidaiton dutse bayan miliyoyin shekaru na canje-canje a fannin ƙasa, ma'adinan ciki, feldspar da sauran ma'adanai masu ƙarfi, tsarin yana da matuƙar kauri da daidaito. Idan aka fuskanci tsangwama daga waje, kamar girgizar da aka samu daga aikin manyan kayan aiki da ke kewaye, tushen dutse yana kama da garkuwa mai ƙarfi, wanda zai iya toshewa da rage shi yadda ya kamata, kuma zai iya rage girman girgizar dandamalin iska mai matsin lamba mai tsauri da fiye da kashi 80%, yana samar da tushe mai ƙarfi da karko don motsi mai inganci na dandamalin. A cikin bitar kera guntu na semiconductor, tsarin lithography yana da manyan buƙatu don kwanciyar hankali na dandamalin, kuma tushen granite yana tabbatar da ingantaccen aikin kayan aikin lithography na guntu, yana taimakawa wajen zana tsarin guntu daidai, kuma yana inganta yawan amfanin masana'antar guntu sosai.

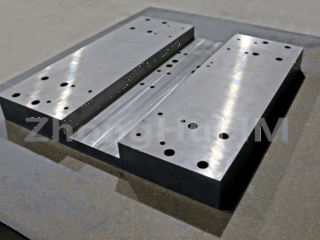

Tushen simintin ma'adinai an yi shi ne da ƙwayoyin ma'adinai da aka haɗa da maƙallin musamman. Tsarinsa na ciki iri ɗaya ne kuma yana da wasu halaye na rage girgiza. Lokacin da ake magance girgiza gabaɗaya, yana iya samar da yanayin aiki mai kyau ga dandamalin. Duk da haka, a fuskar babban ƙarfi da ci gaba da girgiza, ikon rage girgiza na tushen simintin ma'adinai bai isa ba idan aka kwatanta da tushen granite, wanda zai iya haifar da ɗan karkacewa na motsi na dandamali kuma yana shafar daidaiton aikin da aka yi daidai.

Riƙewa daidai: daidaiton fa'idodin halitta da kuma ikon sarrafa ƙarancin faɗaɗawa na wucin gadi

An san Granite saboda ƙarancin yawan faɗaɗa zafi, gabaɗaya 5-7 × 10⁻⁶/℃. A cikin yanayin zafi mai canzawa, girman tushen daidaiton granite yana canzawa kaɗan. A fannin ilmin taurari, daidaitaccen dandamalin iska mai matsin lamba mai tsauri don daidaita ruwan tabarau na hangen nesa an haɗa shi da tushen granite, koda kuwa bambancin zafin rana da dare yana da mahimmanci, yana iya tabbatar da cewa daidaiton wurin da ruwan tabarau yake a matakin submicron, yana taimaka wa masana ilmin taurari su kama canje-canje masu sauƙi na jikin sama mai nisa.

A cikin tsarin ƙira na kayan simintin ma'adinai, ana iya ingantawa da sarrafa halayen faɗaɗa zafi, kuma ma'aunin faɗaɗa zafi na iya zama kusa da ko ma fiye da dutse ta hanyar daidaita rabon ma'adanai da mahaɗan. A wasu kayan aikin aunawa masu saurin zafi, masu saurin daidaitawa, tushen simintin ma'adinai na iya kiyaye girman da ya dace lokacin da zafin jiki ya canza, yana tabbatar da daidaiton motsi na dandamalin. Duk da haka, tushen simintin ma'adinai yana shafar abubuwa kamar tsufa na mahaɗan, kuma ana buƙatar a ƙara lura da daidaiton daidaito na dogon lokaci.

Dorewa: Halayen dutse na halitta mai ƙarfi da kayan haɗin da ke jure gajiya

Taurin granite yana da girma, taurin Mohs zai iya kaiwa 6-7, tare da juriyar lalacewa mai kyau. A dakin gwaje-gwajen kimiyya, dandamalin iska mai matsakaicin matsin lamba mai ƙarfi da ake amfani da shi akai-akai, tushen granite ɗinsa zai iya jure asarar gogayya na dogon lokaci yadda ya kamata, idan aka kwatanta da tushe na yau da kullun, zai iya tsawaita zagayowar kula da dandamalin da fiye da 50%, rage farashin kula da kayan aiki, da kuma tabbatar da ci gaba da aikin binciken kimiyya. Duk da haka, kayan granite suna da rauni kuma suna da sauƙin karyewa idan aka yi musu ba da gangan ba.

Tushen simintin ma'adinai yana da kyawawan halaye na hana gajiya, wanda zai iya tsayayya da lalacewar gajiya yadda ya kamata kuma ya kiyaye amincin tsarin yayin motsi mai tsayi na dogon lokaci na daidaitaccen matsin lamba mai tsayawa a kan dandamalin iyo na iska. A lokaci guda, yana da wani juriya ga sinadarai na gabaɗaya, kuma a cikin muhalli tare da ɗan haɗarin lalata sinadarai, ya fi ƙarfi fiye da tushen granite. Duk da haka, a cikin yanayi mai tsauri kamar zafi mai yawa, mahaɗin da ke cikin tushen simintin ma'adinai na iya shafar, yana rage juriyarsa.

Kudin masana'anta da wahalar sarrafawa: Kalubalen dutse na halitta da kuma iyakokin yin amfani da roba

Haƙar ma'adinai da jigilar kayan dutse suna da sarkakiya, kuma sarrafa su yana buƙatar kayan aiki da fasaha mai ƙarfi sosai. Saboda tsananin tauri da karyewar sa, yana da sauƙin samun matsaloli kamar rugujewar gefen da fashe-fashe a lokacin yankewa, niƙawa, gogewa da sauran hanyoyin aiki, kuma yawan sharar yana da yawa, wanda ke haifar da tsadar masana'antu.

Yin ƙera tushen simintin ma'adinai yana buƙatar takamaiman mold da tsari, kuma farashin haɓaka mold da wuri yana da yawa, amma da zarar an samar da mold ɗin, ana iya samun yawan samarwa kuma ana iya rage farashin naúrar. Tsarin sarrafa shi yana da sauƙi idan aka kwatanta da granite, kuma yana iya cimma buƙatun daidaito mafi girma ta hanyar sarrafa injina, kuma yana da yuwuwar farashi mai araha a cikin manyan yanayi na aikace-aikace.

Lokacin Saƙo: Afrilu-10-2025