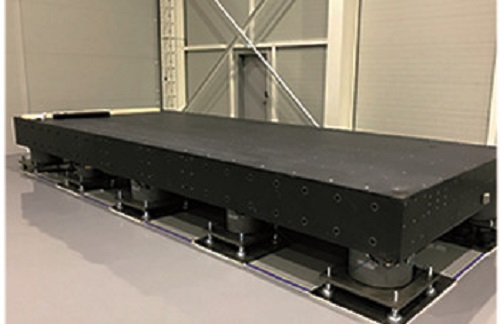

A fannin gwajin semiconductor, zaɓin kayan da dandamalin gwaji ke yi yana taka muhimmiyar rawa a cikin daidaiton gwaji da kwanciyar hankali na kayan aiki. Idan aka kwatanta da kayan ƙarfe na gargajiya, granite yana zama zaɓi mafi kyau ga dandamalin gwajin semiconductor saboda kyakkyawan aikinsa.

Kyakkyawan juriya ga tsatsa yana tabbatar da dorewar aiki na dogon lokaci

A lokacin gwajin semiconductor, galibi ana amfani da sinadarai daban-daban, kamar maganin potassium hydroxide (KOH) da ake amfani da shi don haɓaka hasken rana, da kuma abubuwa masu lalata kamar hydrofluoric acid (HF) da nitric acid (HNO₃) a cikin tsarin etching. Iron ɗin da aka yi da siminti galibi yana ƙunshe da abubuwan ƙarfe. A cikin irin wannan yanayin sinadarai, halayen rage oxidation suna da yuwuwar faruwa. Kwayoyin ƙarfe suna rasa electrons kuma suna fuskantar halayen maye gurbin abubuwa masu acidic a cikin maganin, wanda ke haifar da tsatsa mai sauri a saman, yana haifar da tsatsa da raguwa, da lalata lanƙwasa da daidaiton girma na dandamali.

Sabanin haka, sinadarin ma'adinai na granite yana ba shi juriyar tsatsa mai ban mamaki. Babban sinadarinsa, quartz (SiO₂), yana da kaddarorin sinadarai masu ƙarfi sosai kuma ba ya yin aiki da acid da tushe na yau da kullun. Ma'adanai kamar feldspar suma ba sa aiki a cikin yanayin sinadarai gabaɗaya. Yawancin gwaje-gwaje sun nuna cewa a cikin yanayin sinadarai na gano semiconductor da aka yi kwaikwayon, juriyar tsatsa ta sinadarai na granite ya fi na ƙarfen siminti sau 15. Wannan yana nufin cewa amfani da dandamalin granite na iya rage yawan da farashin kula da kayan aiki da tsatsa ke haifarwa, tsawaita rayuwar kayan aiki, da kuma tabbatar da daidaiton ganowa na dogon lokaci.

Babban kwanciyar hankali, wanda ya cika buƙatun daidaiton gano matakin nanometer

Gwajin Semiconductor yana da matuƙar buƙata don kwanciyar hankali na dandamalin kuma yana buƙatar auna halayen guntu daidai a sikelin nano. Matsakaicin faɗaɗa zafi na ƙarfen siminti yana da girma sosai, kusan 10-12 × 10⁻⁶/℃. Zafin da aikin kayan aikin ganowa ko canjin zafin jiki na yanayi zai haifar da faɗaɗa zafi da matsewar dandamalin ƙarfen siminti mai mahimmanci, wanda ke haifar da karkacewar matsayi tsakanin na'urar ganowa da guntu kuma yana shafar daidaiton ma'auni.

Yawan faɗaɗa zafin granite shine 0.6-5×10⁻⁶/℃ kawai, wanda shine ƙaramin ɓangare ko ma ƙasa da na ƙarfen siminti. Tsarinsa yana da yawa. An kawar da damuwar ciki ta hanyar tsufa na dogon lokaci kuma canjin zafin jiki ba ya shafar shi sosai. Bugu da ƙari, granite yana da ƙarfi mai ƙarfi, tare da tauri sau 2 zuwa 3 fiye da na ƙarfen siminti (daidai yake da HRC > 51), wanda zai iya tsayayya da tasirin waje da girgiza yadda ya kamata da kuma kiyaye madaidaiciyar dandamalin. Misali, a cikin gano da'irar guntu mai inganci, dandamalin granite zai iya sarrafa kuskuren lanƙwasa a cikin ±0.5μm/m, yana tabbatar da cewa kayan aikin ganowa har yanzu suna iya cimma daidaiton gano nanoscale a cikin mahalli masu rikitarwa.

Kyakkyawan kayan hana maganadisu, ƙirƙirar yanayin ganowa mai tsabta

Abubuwan lantarki da na'urori masu auna sigina a cikin kayan gwajin semiconductor suna da matuƙar saurin kamuwa da tsangwama ta hanyar lantarki. Iron ɗin da aka yi amfani da shi wajen yin amfani da shi yana da wani mataki na maganadisu. A cikin yanayin lantarki, zai samar da wani filin maganadisu da aka haifar, wanda zai tsoma baki ga siginar lantarki ta kayan aikin ganowa, wanda zai haifar da karkacewar sigina da kuma bayanan ganowa marasa kyau.

A gefe guda kuma, dutse mai launin toka abu ne mai hana maganadisu kuma ba a raba shi da filayen maganadisu na waje ba. Elektrons na ciki suna wanzuwa a cikin nau'i-nau'i a cikin haɗin sinadarai, kuma tsarin yana da ƙarfi, ba ya shafar ƙarfin lantarki na waje. A cikin yanayin filin maganadisu mai ƙarfi na 10mT, ƙarfin filin maganadisu da aka haifar a saman dutse bai wuce 0.001mT ba, yayin da wanda ke kan saman ƙarfe mai siminti ya kai sama da 8mT. Wannan fasalin yana bawa dandamalin granite damar ƙirƙirar yanayi mai tsabta na lantarki don kayan aikin ganowa, musamman dacewa da yanayi tare da ƙa'idodi masu tsauri don hayaniyar lantarki kamar gano guntu na kwantum da gano da'irar analog mai inganci, yana haɓaka aminci da daidaiton sakamakon ganowa yadda ya kamata.

A fannin gina dandamalin gwajin semiconductor, granite ya zarce kayan ƙarfe da aka yi da siminti saboda fa'idodinsa masu yawa kamar juriya ga tsatsa, kwanciyar hankali da kuma hana maganadisu. Yayin da fasahar semiconductor ke ci gaba zuwa ga daidaito mafi girma, granite zai taka muhimmiyar rawa wajen tabbatar da aikin kayan gwaji da kuma haɓaka ci gaban masana'antar semiconductor.

Lokacin Saƙo: Mayu-15-2025