;

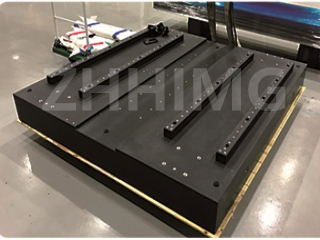

A cikin masana'antar semiconductor, duba wafer muhimmin abu ne don tabbatar da inganci da aikin guntu, kuma daidaito da kwanciyar hankali na teburin dubawa suna taka muhimmiyar rawa a cikin sakamakon ganowa. Tushen dutse mai ban mamaki tare da halaye na musamman, ya zama zaɓi mafi kyau ga teburin duba wafer na semiconductor, wanda ke biye daga nazarin girma dabam-dabam a gare ku.

Da farko, girman garantin daidaito

1. Tsabta da daidaito mai girma: Ana sarrafa tushen granite ta hanyar fasahar sarrafawa mai zurfi, kuma tsattsagewar na iya kaiwa ±0.001mm/m ko ma mafi girman daidaito, kuma madaidaiciyar ita ma tana da kyau sosai. A cikin tsarin duba wafer, babban matakin daidaito yana ba da tallafi mai ƙarfi ga wafer kuma yana tabbatar da daidaito tsakanin binciken kayan aikin dubawa da haɗin solder akan saman wafer.

2. Ƙarancin yawan faɗaɗa zafi: masana'antar semiconductor tana da saurin kamuwa da canje-canjen zafin jiki, kuma yawan faɗaɗa zafi na granite yana da ƙasa sosai, yawanci kusan 5×10⁻⁶/℃. Lokacin da dandamalin ganowa ke aiki, koda kuwa zafin yanayi yana canzawa, girman tushen granite yana canzawa kaɗan. Misali, a cikin bitar zafi mai yawa a lokacin rani, zafin dandamalin gano tushe na ƙarfe na yau da kullun na iya haifar da canjin matsayin wafer da kayan aikin ganowa, wanda ke shafar daidaiton ganowa; Dandalin gano tushe na granite na iya kiyaye kwanciyar hankali, tabbatar da daidaiton matsayin wafer da kayan aikin ganowa yayin aikin ganowa, da kuma samar da yanayi mai kyau don gano daidaiton matsayi mai kyau.

Na biyu, girman kwanciyar hankali

1. Tsarin da ya dace da juriya da girgiza: Granite bayan shekaru miliyoyi na ayyukan ƙasa, tsarin cikin gida yana da yawa kuma iri ɗaya ne. A cikin yanayi mai rikitarwa na masana'antar semiconductor, girgizar da ke haifar da aikin kayan aiki na gefe da ma'aikatan da ke yawo a kusa yana raguwa ta hanyar tushen granite.

2. Daidaiton amfani na dogon lokaci: idan aka kwatanta da sauran kayan aiki, granite yana da tauri mai yawa, juriya mai ƙarfi, kuma taurin Mohs zai iya kaiwa 6-7. Ba a saurin sa saman tushen granite a lokacin loda wafer akai-akai, sauke kaya da ayyukan dubawa. Dangane da ainihin amfani da ƙididdigar bayanai, amfani da teburin gwajin tushen granite, aiki mai ci gaba bayan awanni 5000, daidaiton lanƙwasa da madaidaiciyar daidaito har yanzu ana iya kiyaye shi a sama da kashi 98% na daidaiton farko, rage kayan aiki saboda lalacewa na tushe wanda ke haifar da daidaito na yau da kullun da lokutan kulawa, rage farashin aiki na kasuwanci, don tabbatar da kwanciyar hankali na dogon lokaci na aikin gwaji.

Na uku, girman tsabta da hana tsangwama

1. Ƙarancin ƙura: yanayin masana'antar semiconductor yana buƙatar tsafta sosai, kuma kayan granite ɗin kansa yana da ƙarfi kuma ba shi da sauƙin samar da ƙura. A lokacin aikin dandalin gwaji, ana guje wa ƙurar da tushe ke samarwa don gurɓata wafer ɗin, kuma haɗarin gajeren da'ira da buɗewa da ƙura ke haifarwa yana raguwa. A yankin duba wafer na wurin bita mara ƙura, yawan ƙurar da ke kewaye da teburin duba tushen granite koyaushe ana sarrafa shi zuwa ƙasa sosai, yana biyan buƙatun tsafta na masana'antar semiconductor.

2. Babu tsangwama ta maganadisu: kayan aikin ganowa suna da saurin kamuwa da yanayin lantarki, kuma granite abu ne da ba shi da ƙarfin maganadisu, wanda ba zai tsoma baki ga siginar lantarki ta kayan aikin ganowa ba. A cikin amfani da gano hasken lantarki da sauran fasahar gwaji waɗanda ke buƙatar yanayin lantarki mai ƙarfi sosai, tushen granite yana tabbatar da ingantaccen watsa siginar lantarki ta kayan aikin ganowa kuma yana tabbatar da daidaiton sakamakon gwajin. Misali, lokacin da aka gwada wafer don ingantaccen aikin lantarki, tushen granite mara ƙarfin maganadisu yana guje wa tsangwama ga siginar gano wutar lantarki da ƙarfin lantarki, don haka bayanan ganowa da gaske suna nuna halayen wutar lantarki na wafer.

Lokacin Saƙo: Maris-31-2025