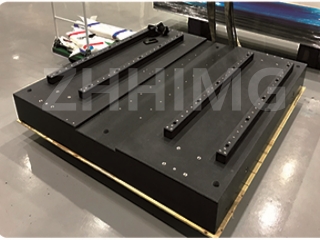

Kayan aikin injin granite na musamman suna da fannoni daban-daban na amfani saboda halaye da halaye daban-daban da suke da su. Waɗannan kayan aikin injin granite an yi su ne da kayan granite masu inganci, wanda aka san shi da dorewa, tauri, da juriya ga lalacewa da tsagewa. Saboda haka, ana amfani da su sosai a masana'antu daban-daban waɗanda ke buƙatar daidaito da daidaito mai yawa a cikin ayyukansu. A cikin wannan labarin, za mu duba wasu fannoni na amfani da kayan aikin injin granite na musamman.

1. Masana'antar Injiniyan Daidaito

Ana amfani da kayan aikin injinan granite na musamman sosai a masana'antar injiniyan daidaito, wanda ya haɗa da masana'antar likitanci, motoci, sararin samaniya, da lantarki. Ana amfani da su azaman faranti na tushe, tebura na aiki, da kayan aunawa a cikin kayan aikin injinan daidaito. Granite yana ba da kwanciyar hankali mai ƙarfi, wanda yake da mahimmanci a masana'antar daidaito don cimma daidaiton da ake so, kuma yana da juriya ga abubuwan muhalli kamar canjin zafin jiki da girgiza.

2. Masana'antar Tsarin Ma'auni

Ana kuma amfani da kayan aikin injin granite na musamman a masana'antar metrology, wanda ya haɗa da aunawa da daidaita siffofi na girma da na geometric. Ana amfani da kayan aikin injin granite azaman tushen aunawa, faranti na saman, da kuma ƙa'idodin daidaita kayan aikin injin. Babban kwanciyar hankali da siffa mai kyau na granite yana taimakawa wajen cimma daidaiton ma'auni mai girma, wanda yake da mahimmanci a masana'antar metrology.

3. Masana'antar Marufi

Masana'antar marufi ta ƙunshi samar da kayan marufi iri-iri kamar kwalaye, kwalabe, da kwantena. Ana amfani da kayan injin granite na musamman a cikin injinan marufi kamar injinan cikawa, injinan rufewa, da injinan lakabi. Abubuwan da aka yi amfani da su a cikin granite suna ba da kwanciyar hankali da juriya ga lalacewa, wanda ke taimakawa wajen inganta ingancin tsarin marufi da rage lokacin aiki.

4. Masana'antar Gilashi

Masana'antar gilashi ta ƙunshi samar da kayayyaki daban-daban na gilashi kamar zanen gado, kwalabe, da kwantena. Ana amfani da kayan aikin injin granite na musamman a cikin kayan aikin ƙera gilashi, kamar injin yanke gilashi da goge gilashi. Babban tauri da juriyar lalacewa na granite suna taimakawa wajen inganta daidaito da ingancin tsarin ƙera gilashi.

5. Masana'antar Semiconductor

Masana'antar semiconductor ta ƙunshi samar da kayan lantarki kamar ƙananan na'urori masu kwakwalwa da kuma da'irori masu haɗawa. Ana amfani da kayan aikin injin granite na musamman a cikin kayan aikin kera semiconductor, kamar injinan duba wafer da injinan lithography. Babban kwanciyar hankali da lanƙwasa na granite suna taimakawa wajen cimma daidaito da daidaito mai yawa a cikin tsarin kera.

6. Masana'antar Abinci

Masana'antar abinci ta ƙunshi samar da kayayyakin abinci iri-iri kamar su abun ciye-ciye, abubuwan sha, da kayayyakin kiwo. Ana amfani da kayan aikin injin granite na musamman a cikin kayan aikin sarrafa abinci, kamar injin yankewa da niƙa. Babban tauri da juriyar lalacewa na granite suna taimakawa wajen inganta inganci da tsaftar tsarin sarrafa abinci.

A ƙarshe, kayan aikin injinan granite na musamman suna da fannoni daban-daban na amfani, gami da injiniyan daidaito, ilimin metrology, marufi, gilashi, semiconductor, da masana'antun abinci. Waɗannan kayan aikin suna ba da kwanciyar hankali, daidaito, da juriya ga lalacewa, waɗanda suke da mahimmanci a masana'antu daban-daban waɗanda ke buƙatar babban daidaito da daidaito a cikin ayyukansu. Zuba jari a cikin kayan aikin injinan granite na musamman na iya taimaka wa 'yan kasuwa inganta ingancinsu, rage lokacin aiki, da ƙara riba.

Lokacin Saƙo: Oktoba-13-2023