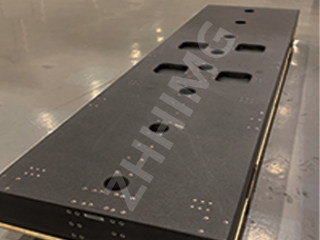

Granite dutse ne na halitta wanda ke da kyakkyawan kwanciyar hankali, ƙarancin faɗaɗa zafi, da kuma juriya mai yawa, wanda hakan ya sa ya zama zaɓi mafi dacewa ga aikace-aikacen masana'antu da yawa, gami da samfuran sarrafa laser. Tare da ƙaruwar buƙatar injuna da kayan aiki na masana'antu masu inganci, granite ya zama sanannen abu don gina sansanonin injina tare da ƙarin daidaito da kwanciyar hankali, waɗanda suke da mahimmanci ga samfuran sarrafa laser. Ga wasu daga cikin fannoni na amfani da tushen granite don samfuran sarrafa laser:

1. Injinan Yanke Laser

Daidaiton injunan yanke laser yana da matuƙar muhimmanci a masana'antar kera. Granite abu ne mai kyau ga waɗannan injunan domin yana ba da kwanciyar hankali mai kyau na zafi, wanda ke ba injunan damar samar da yanke mai santsi da daidaito. Ƙarancin faɗuwar zafi yana tabbatar da cewa tushen injin ba ya faɗaɗa ko ya yi ƙunci da zafi yayin yanke laser, wanda ke tabbatar da ingancin yankewa a cikin kayan daban-daban.

2. Injinan Zane-zanen Laser

Ana amfani da injunan sassaka na Laser don ƙirƙirar ƙira mai kyau a kan saman tauri, kamar ƙarfe, itace, da granite. Daidaiton da ake buƙata don waɗannan injunan ya sa granite ya zama kayan tushe mafi kyau domin yana tabbatar da daidaito da juriya ga girgiza. Ƙarfin granite yana tabbatar da cewa tushen injin ba ya motsawa ko girgiza yayin sassaka, wanda ke haifar da ƙira mai kyau da daidaito.

3. Injinan Alamar Laser

Ana amfani da injunan alama na Laser don ƙara alamomi na dindindin a saman daban-daban, ciki har da ƙarfe, robobi, da yumbu. Granite abu ne da aka fi so ga tushen injin domin yana ba da kyawawan kaddarorin damshi, yana rage tasirin girgiza akan injin yayin amfani. Kwanciyar granite yana tabbatar da ƙarancin motsi yayin yin alama, wanda ke haifar da daidaito da daidaiton alamomi.

4. Injinan walda na Laser

Ana amfani da injunan walda na Laser don haɗa abubuwa daban-daban, gami da ƙarfe, robobi, da yumbu. Daidaiton da ake buƙata don waɗannan injunan ya sa granite ya zama kayan tushe mai kyau. Ƙarancin faɗaɗa zafi da kuma ƙarfinsa yana tabbatar da kwanciyar hankali da ƙarancin motsi yayin aikin walda, yana tabbatar da daidaito da daidaiton walda.

5. Injinan haƙa Laser

Ana amfani da injunan haƙa Laser don ƙirƙirar ramuka masu daidaito a cikin nau'ikan kayayyaki daban-daban, gami da ƙarfe da yumbu. Daidaiton da ake buƙata don waɗannan injunan ya sa granite ya zama kayan tushe mafi kyau, yana ba da kyakkyawan kwanciyar hankali da ƙarancin ƙimar faɗaɗa zafi. Wannan yana tabbatar da haƙa mai kyau tare da ƙarancin ɓarna ko lalacewa ga kayan.

A ƙarshe, tushen granite abu ne mai kyau don gina tushen injina don samfuran sarrafa laser saboda ƙarfinsa, juriyarsa, da ƙarancin yawan faɗaɗa zafi. Ƙara daidaito da daidaito na waɗannan injunan suna da mahimmanci ga aikace-aikacen masana'antu na masana'antu, wanda hakan ya sa granite ya zama mafi kyawun abu ga waɗannan injunan. Sakamakon haka, tushen granite zai ci gaba da zama zaɓi mai shahara ga samfuran sarrafa laser a masana'antu daban-daban.

Lokacin Saƙo: Nuwamba-10-2023