Granite dutse ne na halitta wanda aka samar ta hanyar sanyaya da ƙarfafa magma ko lava na aman wuta. Abu ne mai kauri da dorewa wanda yake da matuƙar juriya ga karce, tabo, da zafi. Ana amfani da granite sosai a masana'antar gini don kayan gini kamar kan tebur, bene, da facades saboda ƙarfi da dorewarsa. Baya ga waɗannan aikace-aikacen, granite ya kuma sami hanyarsa ta shiga masana'antar kayan haɗa kayan aiki daidai, inda ake amfani da shi sosai a matsayin kayan tushe.

Ana amfani da na'urorin haɗa na'urori daidai gwargwado a fannoni daban-daban kamar na mota, jiragen sama, da na likitanci, inda ake buƙatar daidaito da aminci. Ana buƙatar kayan tushe don waɗannan na'urori waɗanda za su iya samar da kyakkyawan damƙar girgiza, ƙarfi mai yawa, da kwanciyar hankali na zafi. Granite ya cika duk waɗannan buƙatun, wanda hakan ya sa ya zama zaɓi mafi kyau ga tushen na'urorin haɗa na'urori daidai gwargwado.

Ɗaya daga cikin manyan aikace-aikacen granite a cikin na'urorin haɗa daidaito shine wajen samar da injunan aunawa masu daidaitawa (CMMs). Ana amfani da CMMs a masana'antun masana'antu don auna girman abubuwan da aka haɗa zuwa babban daidaito. Waɗannan injunan suna amfani da tushen granite saboda yana samar da dandamali mai karko da aminci ga tsarin aunawa. Granite yana da ƙarancin ma'aunin faɗaɗa zafi, wanda ke nufin yana da matuƙar juriya ga canje-canje a zafin jiki. Wannan ya sa ya zama kayan aiki mai kyau don kiyaye daidaiton tsarin aunawa.

Ana kuma amfani da dutse mai daraja sosai wajen samar da tsarin daidaita haske. Ana amfani da waɗannan tsarin don daidaita abubuwan gani zuwa babban matakin daidaito. Kayan tushe na dutse mai daraja yana da mahimmanci ga waɗannan tsarin saboda yana ba da babban matakin tauri, wanda ake buƙata don kiyaye daidaiton abubuwan gani. Granite kuma yana da matuƙar juriya ga girgiza, wanda hakan ya sa ya dace da amfani a cikin muhalli inda matakan girgiza suke da yawa, kamar masana'antar kera.

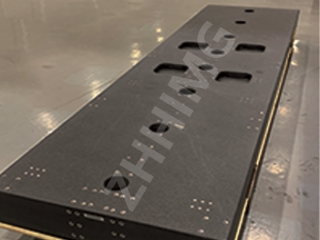

Wani amfani da granite a cikin na'urorin haɗa kayan aiki daidai shine samar da kayan aikin kera semiconductor. Kera semiconductor yana buƙatar babban matakin daidaito don tabbatar da cewa an ƙera kayan aikin daidai gwargwado. Tushen granite yana ba da kwanciyar hankali da tauri da ake buƙata don kayan aikin kera, wanda ke taimakawa wajen tabbatar da cewa an ƙera kayan aikin daidai gwargwado.

Baya ga waɗannan aikace-aikacen, ana amfani da granite wajen samar da kayan aikin dakin gwaje-gwaje, kamar ma'aunin auna nauyi da kayan aikin spectroscopy. Waɗannan na'urori suna buƙatar babban matakin kwanciyar hankali don tabbatar da daidaiton ma'auni. Tushen granite yana samar da kwanciyar hankali da tauri da ake buƙata ga waɗannan nau'ikan na'urori, wanda hakan ya sa ya zama zaɓi mafi kyau.

A ƙarshe, granite abu ne mai matuƙar amfani wanda aka yi amfani da shi sosai a masana'antar injiniyan daidaito. Abubuwan da ke tattare da shi na tauri mai ƙarfi, rage girgiza, da kuma kwanciyar hankali na zafi sun sa ya zama zaɓi mafi kyau ga kayan tushe na na'urorin haɗa daidaito. Daga CMMs zuwa kayan aikin kera semiconductor, granite ya sami hanyarsa ta shiga cikin aikace-aikace iri-iri, yana taimakawa wajen tabbatar da cewa na'urorin da aka ƙera sun kai ga daidaito da aminci. Yayin da buƙatar ƙarin kayan haɗin ke ci gaba da ƙaruwa, yana yiwuwa amfani da granite a cikin injiniyan daidaito zai ci gaba da ƙaruwa.

Lokacin Saƙo: Nuwamba-21-2023