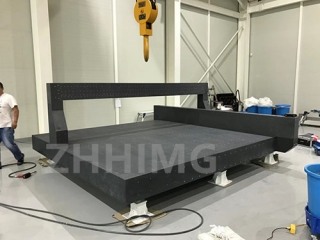

Ana amfani da gadon injin granite sosai a cikin kayayyakin Wafer Processing Equipment saboda kyawawan halayensa. Granite dutse ne mai kama da dutse mai kama da wuta wanda aka san shi da juriya mai yawa, tauri, da juriya ga lalacewa da tsagewa. Sakamakon haka, granite ya sami amfani mai yawa a masana'antar masana'antu a matsayin kayan aiki don gadajen injina a aikace-aikace daban-daban, musamman waɗanda ke buƙatar babban matakin daidaito da kwanciyar hankali. Ga wasu daga cikin fannoni na amfani da gadon injin granite don samfuran Wafer Processing Equipment:

1. Masana'antar Semiconductor

Kera na'urorin Semiconductor yana ɗaya daga cikin mafi mahimmanci da rikitarwa a masana'antar lantarki. Samar da wafers masu inganci yana buƙatar amfani da kayan aiki masu inganci waɗanda ke iya cimma juriya na ƙasa da micron ɗaya. Saboda haka, ana amfani da gadajen injin granite a cikin samfuran Kayan Aikin Sarrafa Wafer don tabbatar da cewa injinan suna kiyaye daidaito, kwanciyar hankali, da kuma maimaituwa a tsawon lokaci na amfani. Bugu da ƙari, gadajen injin granite na iya shan girgizar da aka samar yayin aikin ƙera, yana rage haɗarin lalacewar wafers masu laushi da sauran abubuwan haɗin.

2. Kera na'urorin gani

Kera na'urorin gani wani fanni ne na aikace-aikacen gadajen injin granite a cikin kayayyakin Wafer Processing Equipment. Ana amfani da gadajen injin granite wajen samar da kayan gani masu inganci, kamar ruwan tabarau, prisms, madubai, da matattara, waɗanda ke buƙatar babban matakin kwanciyar hankali da daidaito yayin aikin ƙera su. Gadojin injin granite na iya samar da kwanciyar hankali da tauri ga injinan, suna hana duk wani motsi da ba a so wanda zai iya shafar ingancin samfurin ƙarshe. Bugu da ƙari, gadajen injin granite suna da ƙarancin yawan faɗaɗa zafi, wanda hakan ya sa suka dace da amfani a cikin yanayin da zafin jiki ke sarrafawa.

3. Kera Kayan Aikin Likitanci

Kera kayan aikin likitanci fanni ne na musamman wanda ke buƙatar daidaito da daidaito wajen samar da abubuwa daban-daban, kamar su dashen kayan daki, na roba, da kayan aikin tiyata. Ana amfani da gadajen injinan granite a cikin kayayyakin Wafer Processing Equipment yayin ƙera kayan aikin likitanci, don tabbatar da cewa injunan za su iya kiyaye daidaitonsu da kuma maimaituwa a kan lokaci. Bugu da ƙari, gadajen injinan granite suna da sauƙin tsaftacewa, wanda hakan ke sauƙaƙa kiyaye tsafta da rashin tsafta da ake buƙata a ƙera kayan aikin likita.

4. Tashar Jiragen Sama da Tsaro

Masana'antun sararin samaniya da tsaro su ne biyu daga cikin aikace-aikacen da suka fi wahala a cikin kayayyakin Wafer Processing Equipment. Waɗannan masana'antu suna buƙatar samar da kayan da za su iya jure yanayin zafi mai tsanani, matsin lamba, girgiza, da girgiza. Ana amfani da gadajen injinan granite a cikin waɗannan masana'antu don samar da dandamali mai ɗorewa da tsauri ga injunan da ke ƙera muhimman abubuwa, kamar tsarin jagorar makamai masu linzami, injunan jet, da abubuwan tauraron ɗan adam. Bugu da ƙari, gadajen injinan granite suna da ikon jure yanayin muhalli mai tsanani kuma suna da kyawawan halaye na juriyar girgiza, wanda hakan ya sa su zama zaɓi mafi kyau don aikace-aikacen sararin samaniya da tsaro.

A ƙarshe, kayayyakin Kayan Aikin Sarrafa Wafer suna taka muhimmiyar rawa wajen kera sassa daban-daban a masana'antu daban-daban. Gadojin injinan Granite muhimman sassan kayayyakin Kayan Aikin Sarrafa Wafer ne, suna samar da kwanciyar hankali, daidaito, da aminci da ake buƙata don aikace-aikacen da suka dace. Tare da kyawawan halayensu, gadajen injinan granite sun zama zaɓi mai shahara don aikace-aikace a masana'antar semiconductor, kera na'urorin gani, kera kayan aikin likita, da kuma sararin samaniya da tsaro.

Lokacin Saƙo: Disamba-29-2023