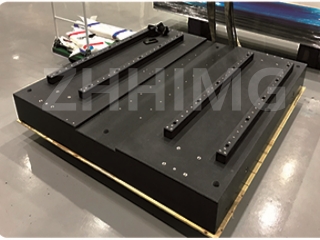

An tabbatar da cewa sassan injinan granite suna da matuƙar muhimmanci ga na'urorin sarrafa daidaito. Halayensu na asali na tauri mai yawa, kwanciyar hankali mai girma, ƙarancin faɗaɗa zafi, da kuma juriyar tsatsa mai kyau sun sa su zama dole ga aikace-aikace inda daidaito da daidaito suke da mahimmanci. Yawancin masana'antu sun haɗa da amfani da sassan injinan granite, gami da metrology, masana'antar semiconductor, kayan aikin gani, da kuma sararin samaniya.

A aikace-aikacen ilimin metrology, auna daidaito yana da matuƙar muhimmanci, kuma sassan injiniya na granite suna aiki a matsayin mizanin tunani mai dacewa don dalilai na daidaitawa. Masana kimiyyar metrology suna amfani da faranti na granite da cubes don saita jiragen sama da wuraren tunani, bi da bi. Waɗannan abubuwan suna samar da saman da ke da faɗi da kwanciyar hankali don auna daidai na ƙananan fasaloli, kamar kauri, tsayi, da siffa. Ingantaccen daidaiton sassan injiniya na granite yana tabbatar da cewa daidaitonsu ya kasance ba tare da wani jinkiri ba akan lokaci, wanda hakan ya sa suka dace da amfani na dogon lokaci a fannin metrology.

A fannin kera semiconductor, daidaito da ingancin kayayyakin suna da matuƙar muhimmanci ga aiki da amincinsu. Abubuwan da ke cikin injinan granite kamar su chucks, wafer carriers, da die pads suna ba da dandamali mai ɗorewa da daidaito don sarrafawa da haɗa wafers na semiconductor. Babban tauri da ƙarancin faɗaɗa zafi na abubuwan da ke cikin granite suna taimakawa wajen rage faruwar warping da tarkace yayin sarrafawa, wanda ke haifar da ingantaccen amfani da kuma ƙarancin lahani. Kyakkyawan juriyar tsatsa na granite yana tabbatar da cewa waɗannan abubuwan suna da aminci da ƙarfi a cikin mawuyacin yanayi na sinadarai.

A fannin kayan aikin gani, buƙatun daidaito da daidaito suna da yawa. Abubuwan da aka ƙera na dutse suna ba da tushe mai ƙarfi da rashin girgiza don haɓakawa da daidaita kayan aikin gani kamar na'urorin hangen nesa, masu auna zafin jiki, da tsarin laser. Ƙarancin faɗaɗa zafi na kayan aikin injinan dutse yana rage tasirin canjin zafin jiki akan aikin gani na kayan aikin, yana inganta daidaito da amincin su. Bugu da ƙari, babban taurin sassan dutse yana ba da damar gina manyan na'urori masu hangen nesa masu nauyi ba tare da lalata kwanciyar hankalinsu ba.

A aikace-aikacen sararin samaniya, amfani da kayan aikin injiniya na granite yana ƙara shahara saboda sauƙin nauyi, ƙarfinsa mai yawa, da kuma juriya ga lalacewar muhalli. Haɗaɗɗun kayan aikin da aka yi da dutse, kamar "Granitium," suna samun sha'awa a matsayin kayan aiki mafi kyau don gina kayan aikin injiniya masu sauƙi a cikin jiragen sama da tauraron ɗan adam. Waɗannan kayan suna ba da kyawawan halaye na injiniya da zafi waɗanda suke da mahimmanci ga aikin tsarin daidaito a sararin samaniya da jirgin sama.

A ƙarshe, sassan injinan granite suna taka muhimmiyar rawa wajen haɓaka da kuma sarrafa samfuran na'urorin sarrafa daidaito a masana'antu daban-daban. Haɗinsu na musamman na halaye, gami da babban tauri, ƙarancin faɗaɗa zafi, da kyakkyawan kwanciyar hankali na girma, yana sa su zama mahimmanci ga aikace-aikacen da ke buƙatar ma'auni daidai, ingantaccen sarrafawa, da ingantaccen aiki. Yanayin sassa daban-daban na sassan granite ya haifar da amfani da su a cikin na'urori da yawa, gami da kayan aikin metrology, kayan aikin semiconductor, na'urorin gani, da tsarin sararin samaniya. Yayin da fasaha ke ci gaba, ana sa ran amfani da sassan injinan granite zai haɓaka, wanda ke ƙara haɓaka daidaito da amincin tsarin masana'antu na zamani.

Lokacin Saƙo: Nuwamba-25-2023