A fannin kera daidaito, kuskuren da aka saba gani shine "yawan yawa = ƙarfi mai ƙarfi = daidaito mafi girma". Tushen granite, tare da yawa na 2.6-2.8g/cm³ (7.86g/cm³ don ƙarfe mai siminti), ya cimma daidaito fiye da na micrometers ko ma nanometers. Bayan wannan abin da ya faru "mai adawa da fahimta" akwai haɗin gwiwa mai zurfi na ilimin ma'adinai, injiniyoyi da dabarun sarrafawa. Mai zuwa yana nazarin ƙa'idodin kimiyya daga manyan fannoni guda huɗu.

1. Yawan ≠ Tauri: Matsayin da ke da mahimmanci na tsarin kayan

Tsarin lu'ulu'u na "sabon zuma na halitta" na granite

Granite ya ƙunshi lu'ulu'u na ma'adinai kamar quartz (SiO₂) da feldspar (KAlSi₃O₈), waɗanda ke da alaƙa da haɗin ionic/covalent, suna samar da tsari mai kama da saƙar zuma. Wannan tsari yana ba shi siffofi na musamman:

Ƙarfin matsewa yana kama da na ƙarfen siminti: yana kaiwa 100-200 mpa (100-250 mpa ga ƙarfen simintin toka), amma tsarin roba yana ƙasa (70-100 gpa idan aka kwatanta da 160-200 gpa ga ƙarfen simintin), wanda ke nufin ba zai iya fuskantar lalacewar filastik ba a ƙarƙashin ƙarfi.

Sakin damuwa ta ciki ta halitta: Granite ya tsufa tsawon ɗaruruwan shekaru na ayyukan ilimin ƙasa, kuma matsin lamba na ciki ya kusan kusan sifili. Lokacin da aka sanyaya ƙarfen siminti (tare da saurin sanyaya > 50℃/s), ana samar da matsin lamba na ciki har zuwa 50-100 mpa, wanda ke buƙatar a kawar da shi ta hanyar annealing na wucin gadi. Idan maganin bai yi cikakken bayani ba, yana iya zama mai saurin lalacewa yayin amfani da shi na dogon lokaci.

2. Tsarin ƙarfe mai "laifi da yawa" na ƙarfen siminti

Iron ɗin da aka yi da ƙarfe da carbon ne, kuma yana da lahani kamar flake graphite, pores da kuma raguwar porosity a ciki.

Ma'aunin rarrabuwar Graphite: Flake graphite yayi daidai da "ƙananan fasa" na ciki, wanda ke haifar da raguwar kashi 30%-50% a ainihin yankin ɗaukar nauyi na ƙarfen siminti. Duk da cewa ƙarfin matsewa yana da yawa, ƙarfin lanƙwasa yana da ƙasa (kashi 1/5-1/10 kawai na ƙarfin matsewa), kuma yana iya fashewa saboda yawan damuwa na gida.

Yawan yawa amma ba daidai ba: Iron ɗin da aka yi da siminti yana ɗauke da kashi 2% zuwa 4% na carbon. A lokacin siminti, rabuwar sinadaran carbon na iya haifar da canjin yawa na ±3%, yayin da granite ke da daidaiton rarraba ma'adinai na sama da kashi 95%, wanda ke tabbatar da daidaiton tsarin.

Na biyu, fa'idar daidaiton ƙarancin yawa: rage zafi da girgiza sau biyu

"Fa'idar da ta dace" ta sarrafa nakasar zafi

Yawan faɗaɗa zafin jiki ya bambanta sosai: granite shine 0.6-5×10⁻⁶/℃, yayin da ƙarfen siminti shine 10-12×10⁻⁶/℃. Ɗauki tushen mita 10 a matsayin misali. Lokacin da zafin jiki ya canza da 10℃:

Faɗaɗa da matsewar dutse: 0.06-0.5mm

Faɗaɗa da matse ƙarfen siminti: 1-1.2mm

Wannan bambancin ya sa granite ya zama kusan "babu nakasu" a cikin yanayin da zafin jiki ke sarrafawa daidai (kamar ±0.5℃ a cikin bita na semiconductor), yayin da ƙarfe mai siminti yana buƙatar ƙarin tsarin diyya na zafi.

Bambancin ƙarfin lantarki mai zafi: Matsakaicin ƙarfin lantarki mai zafi na granite shine 2-3W/(m · K), wanda shine 1/20-1/30 na ƙarfe mai siminti (50-80W/(m · K)). A cikin yanayin dumama kayan aiki (kamar lokacin da zafin motar ya kai 60℃), yanayin zafin saman granite bai kai 0.5℃/m ba, yayin da na ƙarfe mai siminti zai iya kaiwa 5-8℃/m, wanda ke haifar da faɗaɗawa ta gida mara daidaituwa kuma yana shafar madaidaiciyar layin jagora.

2. Tasirin "damtsewa ta halitta" na damƙewar girgiza

Tsarin watsa makamashin iyaka na ciki na hatsi: Ƙananan karaya da zamewar iyaka tsakanin lu'ulu'u na granite na iya wargaza kuzarin girgiza cikin sauri, tare da rabon damping na 0.3-0.5 (yayin da ga ƙarfen simintin, 0.05-0.1 ne kawai). Gwajin ya nuna cewa a lokacin girgizar 100Hz:

Yana ɗaukar daƙiƙa 0.1 kafin girman granite ya ruɓe zuwa 10%.

Simintin ƙarfe yana ɗaukar daƙiƙa 0.8

Wannan bambancin yana bawa granite damar daidaita nan take a cikin kayan aiki masu saurin gudu (kamar na'urar daukar hoton kan murfin a cikin mita 2/s), yana guje wa lahani na "alamun girgiza".

Sakamakon juyewar nauyin inertial: Ƙananan yawa yana nufin cewa nauyin ya ƙanƙanta a cikin wannan adadin, kuma ƙarfin inertial (F=ma) da ƙarfin motsi (p=mv) na ɓangaren motsi sun yi ƙasa. Misali, lokacin da aka hanzarta firam ɗin gantry na granite mai mita 10 (mai nauyin tan 12) zuwa 1.5G idan aka kwatanta da firam ɗin ƙarfe mai siminti (tan 20), buƙatar ƙarfin tuƙi ya ragu da kashi 40%, tasirin farawa-tsayawa yana raguwa, kuma daidaiton matsayi yana ƙara inganta.

Iii. Nasara a cikin daidaiton fasahar sarrafawa "mai zaman kanta"

1. Daidaitawa ga aiki mai matuƙar daidaito

"Matsayin kristal" na niƙa da gogewa: Duk da cewa taurin granite (6-7 akan sikelin Mohs) ya fi na ƙarfen simintin ƙarfe (4-5 akan sikelin Mohs), tsarin ma'adinan sa iri ɗaya ne kuma ana iya cire shi ta hanyar atomic ta hanyar goge lu'u-lu'u + magnetorheological (kauri na gogewa ɗaya < 10nm), kuma taurin saman Ra na iya kaiwa 0.02μm (matakin madubi). Duk da haka, saboda kasancewar ƙwayoyin graphite masu laushi a cikin ƙarfen simintin, "tasirin furplough" yana da saurin faruwa yayin niƙa, kuma taurin saman yana da wuya ya zama ƙasa da Ra 0.8μm.

Amfanin "ƙarancin damuwa" na injin CNC: Lokacin sarrafa granite, ƙarfin yankewa shine 1/3 kawai na ƙarfen siminti (saboda ƙarancin yawa da ƙaramin modulus na roba), yana ba da damar saurin juyawa mafi girma (juyin juya 100,000 a minti ɗaya) da ƙimar ciyarwa (5000mm/min), yana rage lalacewa na kayan aiki da haɓaka ingancin sarrafawa. Wani akwati na injinan axis biyar ya nuna cewa lokacin sarrafa ramukan jagorar granite ya fi guntu 25% fiye da na ƙarfen siminti, yayin da daidaiton ya inganta zuwa ±2μm.

2. Bambance-bambance a cikin "tasirin tarin" kurakuran haɗuwa

Haɓakar sarkar nauyin kayan aiki: Ana iya rage yawan abubuwan da ke cikin motar kamar injina da layin jagora da aka haɗa da ƙananan tushe. Misali, lokacin da ƙarfin motar layi ya ragu da kashi 30%, samar da zafi da girgizarsa suma suna raguwa daidai gwargwado, suna samar da kyakkyawan zagaye na "ingantaccen daidaito - rage yawan amfani da makamashi".

Riƙewa daidai na dogon lokaci: Juriyar tsatsa ta granite sau 15 fiye da ƙarfen siminti (quartz yana da juriya ga lalata acid da alkali). A cikin yanayin hazo na acid na semiconductor, canjin yanayin saman bayan shekaru 10 na amfani bai wuce 0.02μm ba, yayin da ake buƙatar a niƙa ƙarfen siminti a gyara shi kowace shekara, tare da kuskuren tarin ±20μm.

Iv. Shaidar Masana'antu: Mafi kyawun Misali na Ƙananan Yawan Kauri ≠ Ƙarancin Aiki

Kayan aikin gwaji na Semiconductor

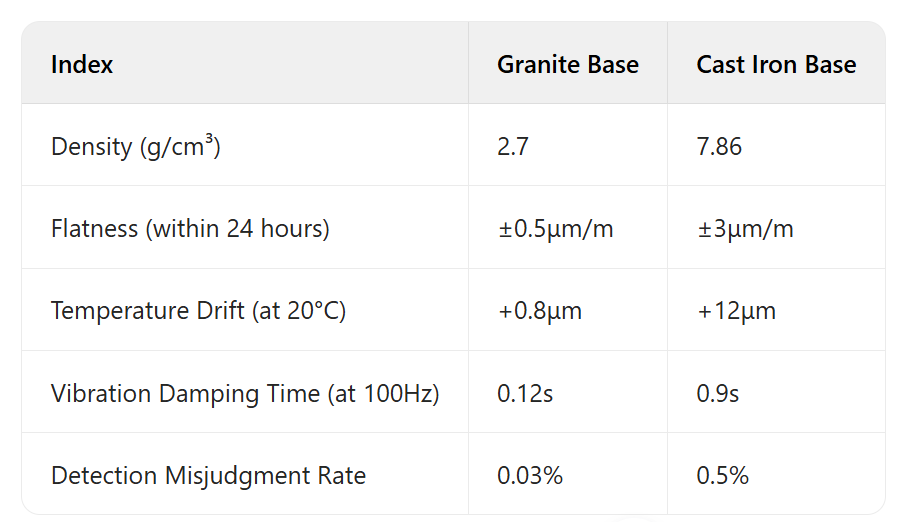

Bayanan kwatantawa na wani dandamalin duba wafer:

2. Kayan aikin gani masu daidaito

An yi amfani da ma'aunin gano infrared na na'urar hangen nesa ta James Webb ta NASA da dutse mai daraja. Ta hanyar amfani da ƙarancin yawansa (rage nauyin tauraron dan adam) da kuma ƙarancin faɗaɗa zafi (tsayawa a yanayin zafi mai ƙarancin -270℃) ne ake tabbatar da daidaiton daidaiton matakin nano, yayin da ake kawar da haɗarin ƙarfen da aka yi amfani da shi wajen yin ƙarfe mai ƙarfi a yanayin zafi mai ƙanƙanta.

Kammalawa: "Hankali Mai Ra'ayi" a fannin kimiyyar kayan aiki

Fa'idar daidaiton tushen dutse a zahiri tana cikin nasarar dabaru na abu na "daidaitaccen tsari > yawa, kwanciyar hankali na girgizar zafi > taurin kai mai sauƙi". Ba wai kawai ƙarancin yawa ba ya zama rauni ba, har ma ya sami tsalle a cikin daidaito ta hanyar matakai kamar rage rashin ƙarfi, inganta sarrafa zafi, da daidaitawa zuwa ingantaccen sarrafawa. Wannan lamari ya bayyana ainihin dokar kera daidaito: halayen kayan abu cikakken daidaito ne na sigogi masu girma dabam-dabam maimakon tarin alamomi guda ɗaya kawai. Tare da haɓaka fasahar nano da kera kore, kayan granite masu ƙarancin yawa da aiki suna sake fasalta fahimtar masana'antu na "nauyi" da "haske", "mai tauri" da "mai sassauƙa", suna buɗe sabbin hanyoyi don kera kayayyaki masu inganci.

Lokacin Saƙo: Mayu-19-2025