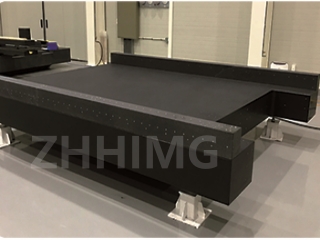

A fannin auna daidaito, injin auna tsayi muhimmin abu ne don tabbatar da daidaiton girma na samfura, kuma aikin kayan tushe yana shafar kwanciyar hankali da tsawon sabis na kayan aiki kai tsaye. A cikin 'yan shekarun nan, yawan injunan auna tsayi sun fara amfani da granite a matsayin kayan tushe. Ɗaya daga cikin mahimman dalilan wannan shine ƙarfin gajiya mai ban mamaki na granite. Bayanan gwaji sun nuna cewa ƙarfin gajiya na kayan granite ya ninka na ƙarfen siminti sau bakwai. Wannan babban fa'ida yana ba da garanti mai ƙarfi don tsawaita tsawon lokacin sabis na tushen injin auna tsayi.

Domin tabbatar da bambancin ƙarfin gajiya tsakanin granite da ƙarfen siminti, ƙungiyar binciken ta gudanar da gwaje-gwaje masu tsauri. Gwajin ya zaɓi samfuran tushen granite da ƙarfen siminti na ƙayyadaddun bayanai iri ɗaya kuma a ƙarƙashin yanayin kwaikwayon yanayin aiki iri ɗaya. Ta hanyar injin gwajin gajiya, ana canza kaya akai-akai ga samfuran tushe na kayan aiki guda biyu don kwaikwayon ƙarfin waje kamar girgiza da matsin lamba da injin auna tsayi ke fuskanta yayin amfani da dogon lokaci. A lokacin gwajin, an yi rikodin tsarin microstructure, yanayin lalacewar saman da matakin lalacewar kayan bayan kowane zagayen lodi.

Bayan gwaje-gwajen da aka yi da yawa na madaurin lodi, sakamakon ya yi kyau kwarai da gaske. An ga fashewar gajiya a bayyane a cikin samfuran tushen ƙarfe bayan ƙaramin adadin zagayowar lodi. Yayin da adadin zagayowar ke ƙaruwa, waɗannan tsage-tsage suna ci gaba da faɗaɗawa da haɗuwa, wanda ke haifar da lalata amincin tsarin kayan da kuma raguwar halayen injinan sa. Duk da haka, samfuran tushen dutse sun fara nuna tsage-tsage masu ƙanƙanta sosai bayan an yi zagayowar lodi sau da yawa fiye da na ƙarfen siminti, kuma saurin yaɗuwar tsagewar ya yi jinkiri sosai. Daga mahangar macroscopic, matakin lalacewar kadarorin injiniya na tushen dutse ya yi ƙasa da na tushen ƙarfe siminti. Ta hanyar nazarin bayanai da lissafi na ƙwararru, a ƙarshe an kammala da cewa ƙarfin gajiya na kayan dutse ya ninka na ƙarfe siminti sau bakwai.

Dalilin da yasa kayan granite ke da irin wannan ƙarfin gajiya yana da alaƙa da tsarinsu na ciki da kuma halayen ma'adinai. Granite dutse ne mai kama da wuta wanda aka samar ta hanyar haɗin lu'ulu'u daban-daban na ma'adinai. Ƙwayoyin ma'adinai da ke cikinsa suna haɗuwa da juna, suna samar da tsari mai yawa da kwanciyar hankali. Wannan tsari yana bawa granite damar wargaza damuwa daidai lokacin da aka fuskanci ƙarfin waje, yana rage abin da ke haifar da yawan damuwa a gida, ta haka yana jinkirta samarwa da faɗaɗa fasawar gajiya yadda ya kamata. Sabanin haka, akwai wasu ƙananan ramuka da ƙazanta a cikin ƙarfe mai siminti. Waɗannan lahani suna zama "ƙasa mai kiwo" don fara fasawar gajiya. Lokacin da aka fuskanci ƙarfin waje, suna iya haifar da yawan damuwa da hanzarta gazawar kayan.

Ga na'urar auna tsayi, ƙarfin gajiya mai yawa na tushen granite yana nufin cewa a lokacin amfani da shi na dogon lokaci, ana iya kiyaye kwanciyar hankali da daidaiton tsarin sosai. An rage kuskuren aunawa da lalacewar gajimare na tushen ya haifar, kuma an inganta ingancin sakamakon aunawa. A halin yanzu, yayin da tushen granite ba shi da saurin lalacewa ga gajiya, yana rage yawan kulawa da farashin maye gurbin kayan aiki sosai, kuma yana tsawaita tsawon rayuwar injin auna tsayi sosai.

A cikin yanayin masana'antu na yau inda buƙatun daidaito na samfura ke ƙara tsauri, kwanciyar hankali na aikin injin auna tsayi, a matsayin muhimmin kayan aiki don kula da inganci, yana da matuƙar muhimmanci. Kayan dutse, tare da ƙarfin gajiyarsa da ya wuce na ƙarfen siminti, yana ba da zaɓi mafi kyau don ƙira da ƙera tushen injin auna tsayi, wanda ya zama sirri mai mahimmanci don tsawaita rayuwar sabis na tushen injin auna tsayi da tabbatar da daidaiton ma'auni daidai. Tabbas zai taka rawa mafi girma wajen haɓaka haɓaka fasahar auna daidai.

Lokacin Saƙo: Mayu-13-2025