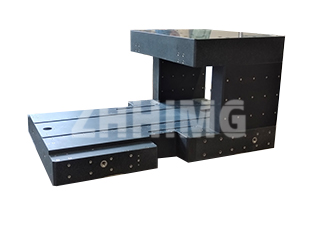

Tsarin gwajin granite daidai shine ginshiƙin ma'auni mai maimaitawa da daidaito. Kafin a ɗauki duk wani kayan aikin granite—daga farantin saman mai sauƙi zuwa murabba'i mai rikitarwa—a matsayin wanda ya dace da amfani, dole ne a tabbatar da daidaitonsa sosai. Masana'antun kamar ZHONGHUI Group (ZHHIMG) suna bin ƙa'idodin kula da inganci masu tsauri, suna tabbatar da dandamali a matakai daban-daban kamar 000, 00, 0, da 1. Wannan takardar shaidar ta dogara ne akan hanyoyin fasaha da aka kafa waɗanda ke bayyana ainihin madaidaicin saman.

Ƙayyade Daidaito: Babban Hanyar

Babban manufar tabbatar da tsarin granite shine a tantance kuskuren lanƙwasa (FE). Wannan kuskuren an bayyana shi a matsayin ƙaramin tazara tsakanin layuka biyu masu layi ɗaya waɗanda ke ɗauke da dukkan wuraren da ke cikin ainihin saman aiki. Masana kimiyyar ƙasa suna amfani da hanyoyi guda huɗu da aka sani don tantance wannan ƙimar:

Hanyoyin Maki Uku da Diagonal: Waɗannan hanyoyin suna ba da kimantawa masu amfani da tushe na yanayin saman. Hanyar Maki Uku tana kafa tsarin ma'aunin kimantawa ta hanyar zaɓar wurare uku da suka rabu a saman, tana bayyana FE ta hanyar nisan da ke tsakanin layukan layi biyu masu layi ɗaya. Hanyar Ma'aunin, wacce galibi ake amfani da ita azaman ma'aunin masana'antu, yawanci tana amfani da kayan aiki masu inganci kamar matakin lantarki tare da farantin gada. A nan, an saita tsarin ma'aunin ma'auni tare da diagonal, yana ba da hanya mai inganci don kama rarraba kurakurai gaba ɗaya a duk saman.

Hanyar Mafi Ƙaramin Mai Nisa Biyu (Mafi Ƙarancin Murabba'i): Wannan ita ce hanya mafi tsauri a lissafi. Tana bayyana matakin tunani a matsayin wanda ke rage jimlar murabba'in nisan daga dukkan wuraren da aka auna zuwa ga jirgin kanta. Wannan hanyar ƙididdiga tana ba da kimantawa mafi daidaito na lanƙwasa amma tana buƙatar ci gaba da sarrafa kwamfuta saboda sarkakiyar lissafin da ke tattare da shi.

Hanyar Ƙaramin Yanki: Wannan dabarar ta yi daidai da ma'anar siffar geometric na lanƙwasa, inda ƙimar kuskuren ke ƙayyade ta hanyar faɗin ƙaramin yanki da ake buƙata don ya ƙunshi duk wuraren saman da aka auna.

Gudanar da Daidaito: Yarjejeniyar Alamar Kira

Bayan daidaitaccen lanƙwasa, kayan aiki na musamman kamar murabba'ai na granite suna buƙatar tabbatar da daidaito tsakanin fuskokin aikinsu. Hanyar nuna alamar kira ta dace sosai da wannan aikin, amma amincinsa ya dogara ne kawai akan aiwatarwa mai kyau.

Dole ne a koyaushe a yi binciken a kan farantin saman da aka yi amfani da shi mai cikakken daidaito, ta amfani da fuskar aunawa ɗaya ta murabba'in granite a matsayin ma'aunin farko, wanda aka daidaita shi da kyau a kan dandamalin. Matakin mahimmanci shine a kafa wuraren aunawa a fuskar da ake dubawa - waɗannan ba bazuwar ba ne. Don tabbatar da cikakken kimantawa, ana buƙatar wurin duba wuri mai nisan kusan 5mm daga gefen saman, tare da tsarin grid mai faɗi daidai a tsakiyar, tare da wuraren da galibi ke raba su da 20mm zuwa 50mm. Wannan grid mai tsauri yana tabbatar da cewa an tsara kowane tsari ta hanyar mai nuna alama.

Abu mafi mahimmanci, lokacin duba fuskar da ta dace, dole ne a juya murabba'in granite digiri 180. Wannan sauyi yana buƙatar kulawa sosai. Bai kamata a taɓa zame kayan aikin a kan farantin nuni ba; dole ne a ɗaga shi a hankali a sake sanya shi a wuri. Wannan muhimmin tsarin sarrafawa yana hana hulɗa mai lalata tsakanin saman biyu da aka yi daidai, yana kare daidaiton murabba'in da dandamalin nuni na dogon lokaci.

Cimma juriyar kayan aikin da suka fi inganci—kamar murabba'ai masu girman Grade 00 na ZHHIMG—shaida ce ta kyawawan halayen zahiri na tushen granite da kuma amfani da waɗannan ƙa'idodin ƙa'idodin metrology masu tsauri.

Lokacin Saƙo: Nuwamba-03-2025