;

A fannin kera na'urorin semiconductor, daidaiton kayan aikin duba wafer kai tsaye yana ƙayyade inganci da yawan guntu. A matsayin harsashin da ke tallafawa abubuwan gano ainihin, daidaiton girman kayan tushe na kayan aiki yana taka muhimmiyar rawa a cikin aikin aiki na dogon lokaci na kayan aikin. Granite da ƙarfe siminti kayan tushe ne guda biyu da aka saba amfani da su don kayan aikin duba wafer. Wani bincike na shekaru 10 ya bayyana manyan bambance-bambancen da ke tsakaninsu dangane da daidaiton girma, yana ba da mahimman bayanai don zaɓar kayan aiki.

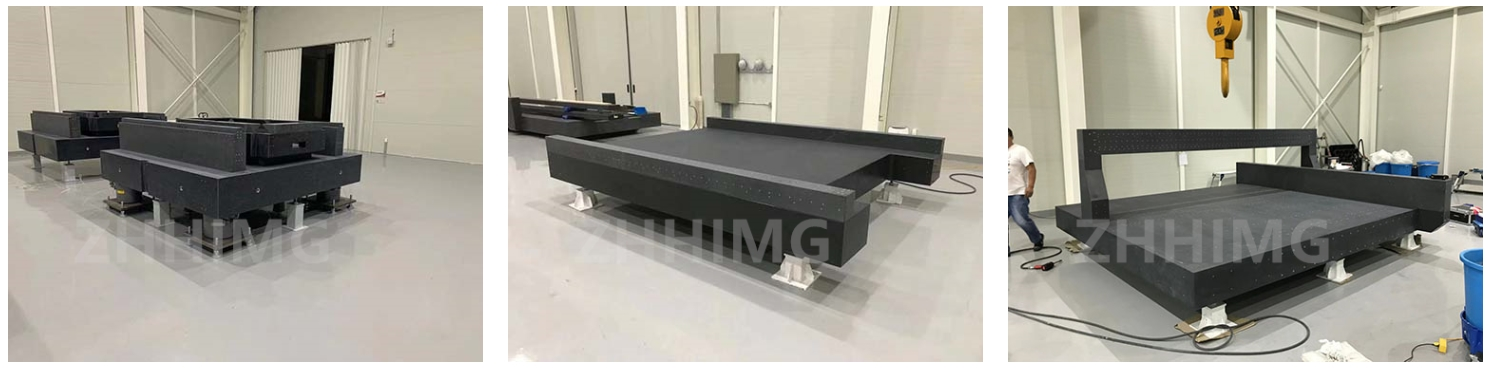

Bayanin Gwaji da Zane

Tsarin samar da wafers na semiconductor yana da matuƙar buƙata don daidaiton ganowa. Ko da karkacewar girma a matakin micrometer na iya haifar da raguwar aikin guntu ko ma gogewa. Don bincika daidaiton girma na granite da ƙarfen siminti yayin amfani na dogon lokaci, ƙungiyar bincike ta tsara gwaje-gwajen da suka kwaikwayi yanayin aiki na gaske. An zaɓi samfuran granite da ƙarfen siminti iri ɗaya kuma an sanya su a cikin ɗakin muhalli inda zafin jiki ya canza daga 15℃ zuwa 35℃ kuma danshi ya canza daga 30% zuwa 70% RH. An kwaikwayi girgizar injiniya yayin aikin kayan aiki ta hanyar teburin girgiza. An auna mahimmin girman samfuran a kowane kwata ta amfani da na'urar laser mai daidaitaccen daidaito, kuma ana ci gaba da yin rikodin bayanan na tsawon shekaru 10.

Sakamakon gwaji: Cikakken fa'idar granite

Shekaru goma na bayanai na gwaji sun nuna cewa tushen granite yana nuna kwanciyar hankali mai ban mamaki. Matsakaicin faɗaɗa zafinsa yana da ƙasa sosai, matsakaicin 4.6×10⁻⁶/℃ kawai. A ƙarƙashin canje-canjen zafin jiki mai tsanani, ana sarrafa karkacewar girma koyaushe a cikin ±0.001mm. A fuskar canje-canjen danshi, tsarin granite mai yawa yana sa ya kusan ba ya shafar shi, kuma babu canje-canjen girma da za a iya aunawa. A cikin yanayin girgizar injiniya, kyawawan halayen damshi na granite suna shan kuzarin girgiza yadda ya kamata, kuma canjin girma yana da ƙanƙanta sosai.

Sabanin haka, ga ƙarfen simintin ƙarfe, matsakaicin ma'aunin faɗaɗa zafinsa ya kai 11×10⁻⁶/℃ - 13×10⁻⁶/℃, kuma matsakaicin karkacewar girma da canje-canjen zafin jiki ke haifarwa cikin shekaru 10 shine ±0.05mm. A cikin yanayi mai danshi, ƙarfen simintin yana da saurin tsatsa da tsatsa. Wasu samfura suna nuna nakasar gida, kuma karkacewar girma tana ƙara ƙaruwa. A ƙarƙashin tasirin girgizar injiniya, ƙarfen simintin yana da ƙarancin aikin rage girgiza kuma girmansa yana canzawa akai-akai, wanda hakan ke sa ya zama da wahala a cika buƙatun dubawa na wafer mai inganci.

Muhimmin dalilin bambancin kwanciyar hankali

An samar da dutse mai daraja tsawon ɗaruruwan shekaru ta hanyar tsarin ƙasa. Tsarinsa na ciki yana da kauri da daidaito, kuma lu'ulu'u na ma'adinai an tsara su da kyau, wanda hakan ke kawar da damuwa ta ciki ta yanayi. Wannan yana sa shi rashin jin daɗi ga canje-canje a cikin abubuwan waje kamar zafin jiki, danshi da girgiza. Ana yin ƙarfe mai kauri ta hanyar tsarin siminti kuma yana da lahani kamar ramuka da ramukan yashi a ciki. A halin yanzu, damuwar da aka samu yayin aikin simintin tana iya haifar da canje-canje a girma a ƙarƙashin ƙarfafa yanayin waje. Halayen ƙarfe na ƙarfe mai kauri suna sa shi ya yi tsatsa saboda danshi, yana hanzarta lalacewar tsari da rage kwanciyar hankali.

Tasirin kayan aikin duba wafer

Kayan aikin duba wafer bisa ga tushen granite, tare da aikin girmansa mai ƙarfi, na iya tabbatar da cewa tsarin dubawa yana riƙe da daidaito mai yawa na dogon lokaci, yana rage rashin fahimta da kuma gano kurakurai da aka samu sakamakon karkatar da daidaiton kayan aiki, da kuma inganta yawan amfanin samfura sosai. A halin yanzu, ƙarancin buƙatun kulawa yana rage cikakken farashin zagayowar rayuwar kayan aiki. Kayan aiki da ke amfani da abubuwan ƙarfe na siminti, saboda rashin kwanciyar hankali na girma, suna buƙatar daidaitawa akai-akai da kulawa. Wannan ba wai kawai yana ƙara farashin aiki ba har ma yana iya shafar ingancin samar da semiconductor saboda rashin daidaito, yana haifar da asarar tattalin arziki.

A ƙarƙashin yanayin da masana'antar semiconductor ke neman ingantaccen daidaito da inganci, zaɓar dutse a matsayin kayan aikin duba wafer babu shakka mataki ne mai kyau don tabbatar da aikin kayan aiki da haɓaka gasawar kamfanoni.

Lokacin Saƙo: Mayu-14-2025