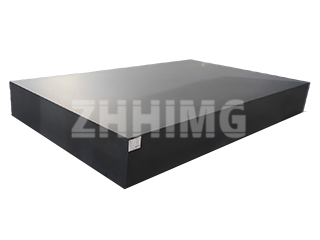

Jagorar Injin da Kula da Farantin Dutse: Farantin saman dutse mai daidaito yana buƙatar injina da kulawa na musamman don tabbatar da daidaitonsa da tsawon rayuwarsa. Kafin a goge, dole ne a fara sarrafa injina da daidaitawa a kwance bisa ga ƙa'idodin sanyawa a cikin sassa uku. Bayan niƙa a kwance, idan injin CNC ba zai iya cimma daidaiton da ake buƙata ba - yawanci isa ga daidaiton Daraja 0 (juriyar 0.01mm/m kamar yadda aka ƙayyade a cikin DIN 876) - kammala hannu ya zama dole don cimma manyan maki masu daidaito kamar Daraja 00 (juriyar 0.005mm/m bisa ga ƙa'idodin ASTM B89.3.7).

Tsarin injin ya ƙunshi matakai masu mahimmanci da yawa. Na farko, niƙa mai ƙarfi yana kafa madaidaicin layi, sannan a biyo baya da ƙarshen layi don cire alamun injin. Niƙa daidai, wanda galibi ana yin sa da hannu, yana gyara saman don cimma juriyar lanƙwasa da kuma ƙaiƙayin saman da ake so (ƙimar Ra ta 0.32-0.63μm, inda Ra ke wakiltar matsakaicin karkacewar bayanin saman). A ƙarshe, dubawa mai kyau yana tabbatar da bin ƙa'idodin fasaha, tare da wuraren aunawa da aka sanya su a cikin dabarun diagonal, gefuna, da tsakiyar layi - yawanci maki 10-50 dangane da girman farantin - don tabbatar da daidaito iri ɗaya.

Sarrafawa da shigarwa suna da tasiri sosai ga daidaito. Saboda taurin granite (taurin Mohs 6-7), ɗagawa mara kyau na iya haifar da nakasa ta dindindin. Don aikace-aikacen da ke buƙatar daidaiton Grade 00, lanƙwasa hannu bayan shigarwa yana da mahimmanci don dawo da daidaiton da aka lalace yayin jigilar kaya. Wannan kulawa ga cikakkun bayanai yana bambanta faranti na saman granite masu inganci daga nau'ikan injina na yau da kullun.

Ayyukan kulawa suna shafar aiki da tsawon rai kai tsaye. Fara da tsaftacewa sosai ta amfani da masu tsaftace pH masu tsaka-tsaki - guje wa abubuwan acidic waɗanda zasu iya goge saman. Daidaitawar shekara-shekara tare da na'urorin auna laser, waɗanda ake iya gano su bisa ga ƙa'idodin NIST, yana tabbatar da ci gaba da daidaito. Lokacin sanya kayan aiki, a bar daidaiton zafi (yawanci mintuna 15-30) don hana kurakuran aunawa daga bambance-bambancen zafin jiki. Kada a taɓa zame abubuwa masu kaifi a saman, domin wannan na iya haifar da ƙananan karce waɗanda ke shafar lanƙwasa.

Jagororin amfani masu kyau sun haɗa da girmama iyakokin kaya don hana lalacewar tsari, kiyaye yanayin muhalli mai ɗorewa (zafin jiki 20±2°C, danshi 50±5%), da kuma amfani da kayan aikin ɗagawa na musamman don guje wa lalacewar ɓangaren da ke raba ƙasa. Ba kamar sauran ƙarfe ba, kwanciyar hankali na zafin granite (0.01ppm/°C) yana rage tasirin muhalli, amma ya kamata a guji canje-canjen zafin jiki kwatsam.

A matsayin kayan aiki na asali a fannin daidaiton yanayin ƙasa, faranti masu takardar shaidar granite (wanda aka amince da shi a ISO 17025) suna aiki a matsayin ma'aunin ma'auni don auna girma. Kula da su yana buƙatar ƙaramin ƙoƙari - kawai a goge su da zane mara lint bayan amfani - babu buƙatar shafa mai ko man shafawa na musamman. Ta hanyar bin waɗannan ƙa'idodin injina da kulawa, faranti masu daidaitacce suna ba da ingantaccen aiki tsawon shekaru da yawa, wanda hakan ke sa su zama dole a dakunan gwaje-gwaje na daidaitawa, kera jiragen sama, da aikace-aikacen injiniya mai inganci.

Lokacin Saƙo: Nuwamba-19-2025