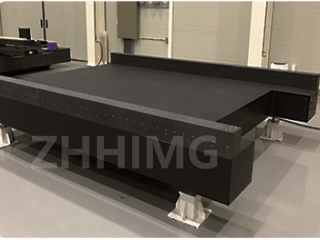

Granite abu ne da aka saba amfani da shi wajen ƙera abubuwan da ake amfani da su a cikin na'urorin semiconductor. Waɗannan sassa, galibi a cikin nau'in chucks da pedestals, suna samar da dandamali mai ɗorewa don motsa da sanya wafers na semiconductor a matakai daban-daban na tsarin ƙera su. Ayyuka da amincin waɗannan sassan granite suna da tasiri ta hanyar abubuwa da yawa, gami da yanayin da ake amfani da su.

Ɗaya daga cikin muhimman abubuwan da ke shafar abubuwan da ke cikin granite a cikin na'urorin semiconductor shine zafin jiki. Granite yana da ƙarancin yawan faɗaɗa zafi, wanda ke nufin yana iya jure yanayin zafi iri-iri ba tare da yaɗuwa ko fashewa ba. Duk da haka, canjin zafin jiki mai tsanani na iya haifar da damuwa a cikin kayan, wanda ke haifar da tsagewa ko wargaza saman. Bugu da ƙari, fallasa ga yanayin zafi mai yawa na dogon lokaci na iya sa kayan ya yi laushi, wanda hakan ke sa shi ya zama mai sauƙin lalacewa da lalacewa.

Danshi wani muhimmin abu ne na muhalli wanda ke shafar aikin sassan granite a cikin na'urorin semiconductor. Yawan zafi na iya haifar da danshi ya shiga cikin farfajiyar granite mai ramuka, wanda ke haifar da wargajewa ko fashewa. Bugu da ƙari, danshi na iya haifar da gajeren wando na lantarki, wanda zai iya lalata kayan lantarki masu laushi waɗanda ake sarrafawa a saman granite. Don hana waɗannan matsalolin, yana da mahimmanci a kiyaye muhallin bushewa yayin aiwatar da kera semiconductor.

Shafar sinadarai kuma muhimmin abu ne idan ana amfani da sassan granite a cikin na'urorin semiconductor. Granite gabaɗaya yana jure wa yawancin sinadarai, amma wasu sinadarai da acid na iya haifar da lalacewa ga samansa. Abubuwan tsaftacewa na yau da kullun kamar isopropyl alcohol ko hydrofluoric acid na iya goge ko lalata saman granite, wanda ke haifar da rashin ƙarfi da raguwar lanƙwasa. Don guje wa waɗannan matsalolin, ya kamata a yi taka-tsantsan lokacin zaɓar masu tsaftacewa da hanyoyin hana lalacewar sinadarai.

Wani abu kuma da ke shafar aikin sassan granite shine girgiza. Girgizar na iya haifar da ƙananan fasa a saman granite, wanda ke haifar da lalacewar lanƙwasa saman. Don rage girgiza, yana da mahimmanci a ɗauki matakai masu dacewa kamar shigar da tsarin keɓewar girgiza da kuma guje wa motsi mara amfani na sassan granite.

A ƙarshe, aikin sassan granite a cikin na'urorin semiconductor yana da tasiri ga abubuwa daban-daban na muhalli, ciki har da zafin jiki, danshi, fallasa sinadarai, da girgiza. Ta hanyar ɗaukar matakan da suka dace don rage fallasa ga waɗannan abubuwan, masana'antun za su iya tabbatar da aminci da tsawon rai na sassan granite a cikin na'urorin semiconductor. Tare da kulawa sosai ga abubuwan muhalli da kuma kulawa mai kyau, sassan granite za su ci gaba da taka muhimmiyar rawa a masana'antar semiconductor.

Lokacin Saƙo: Afrilu-08-2024